Urinal and manufacturing process thereof

A manufacturing process and urinal technology, applied in the field of sanitary ware, can solve the problems of high risk of pipe deformation, gaps in bonding parts, and easy deformation, etc., to achieve the effect of convenient bonding, reliable connection parts, and not easy to scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

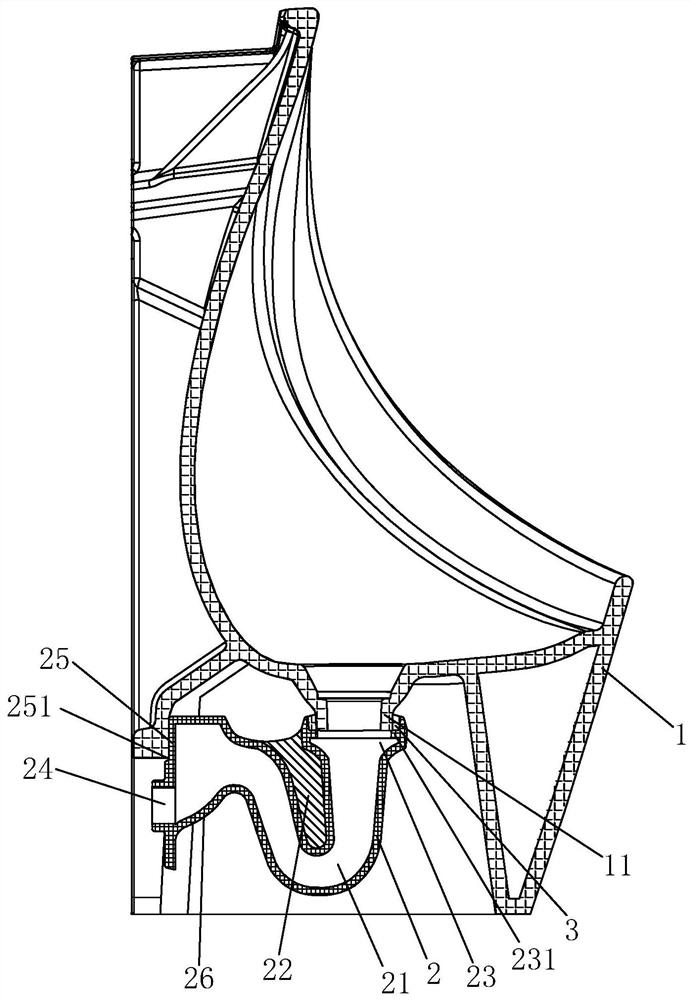

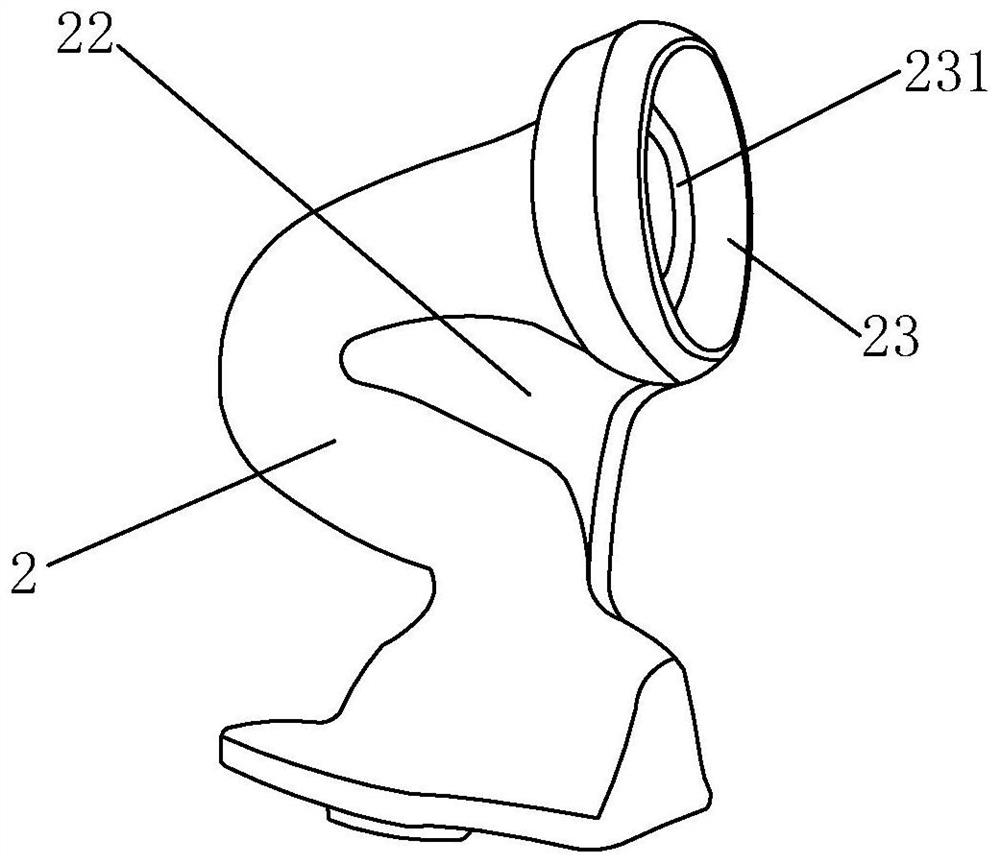

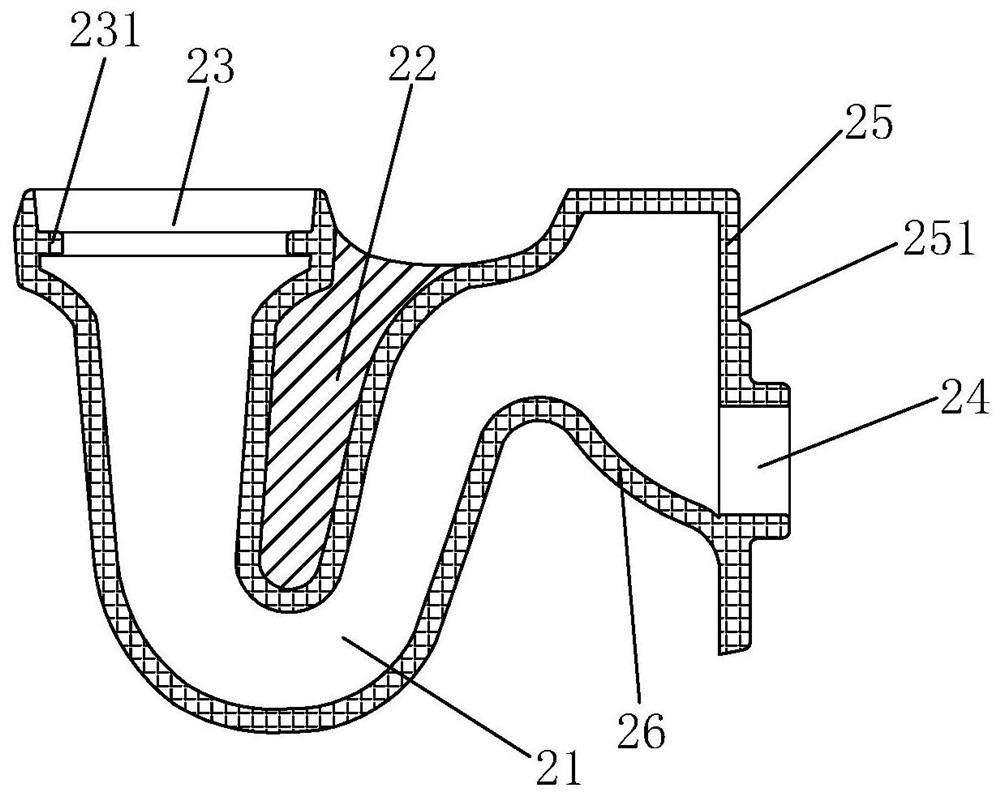

[0030] Examples, see Figure 1-Figure 3 As shown, a urinal of the present invention comprises a urinal body 1 and a sewage pipe 2, and the sewage pipe 2 is provided with a trap 21; the sewage pipe 2 and the urinal body 1 are made of ceramic material, and the sewage pipe 2 and the The toilet body 1 is molded independently, and bonded and fixed in a wet state.

[0031] In this embodiment, the sewage pipe 2 is provided with reinforcing ribs 22 between the two sides of the water trap 21, and the water trap 21 is U-shaped. The rib plate 22 can play a supporting role to prevent the wet billet of the sewage pipe 2 from being deformed due to gravitational force during the drying process, thereby reducing the deformation rate of the sewage pipe 2 after firing.

[0032] In this embodiment, the sewage inlet 23 of the sewage pipeline 2 is sleeved outside the urination part 11 of the urinal body 1, and a ring of positioning flanges 231 is provided in the sewage inlet 23 of the sewage pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com