Sample piece for testing peel strength of paper-based material, manufacturing method and testing method

A technology of peel strength and manufacturing method, which is applied in the direction of applying stable tension/pressure to test the strength of materials, analysis of materials, strength characteristics, etc., which can solve problems such as inability to accurately test product performance indicators, substrate damage or breakage, and avoid damage or break, the effect of accurate testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

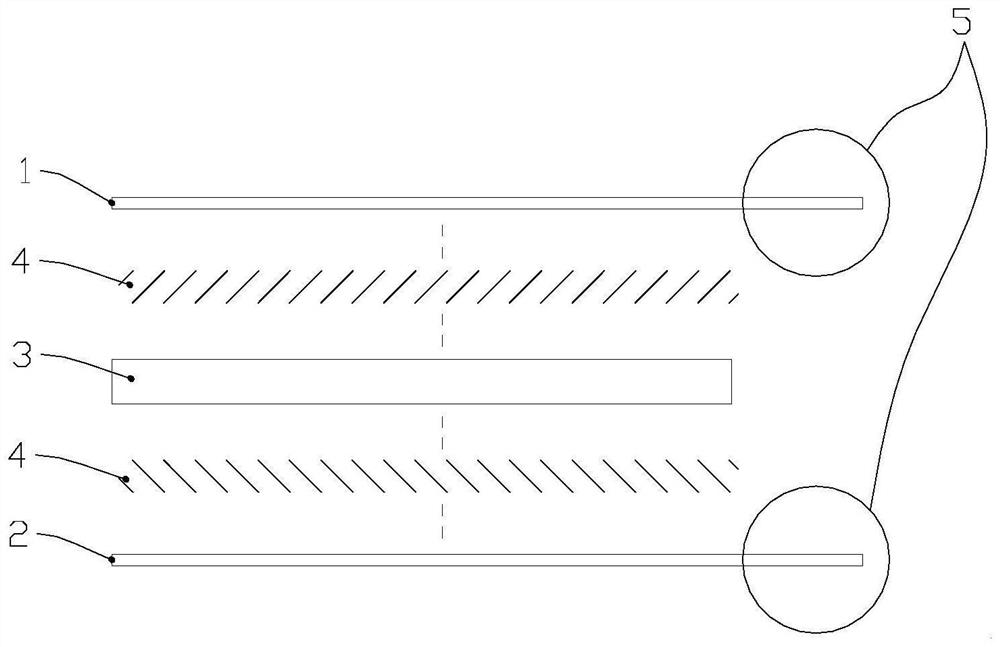

[0043] The sample used for the peel strength test of paper-based materials, including: the first base material 1, the main body of paper-based material 3 and the second base material 2 which are stacked in sequence; The base material main body 3 is connected by an adhesive layer 4, and the adhesive layer 4, the first base material 1 and the second base material 2 all cover the paper base material main body 3; wherein, in the first base material 1 and the second base material 2 At least one of them is a flexible material, and the flexible material is provided with a leading end 5 relative to the main body 3 of the paper-based material for applying force during the test.

[0044] The present invention provides a kind of suitable for paper base, especially the grammage is less than 500g / m 2 Or the test samples of paper base and related paper base products with a thickness of less than 0.5mm, through the setting of the base material on both sides, play a role in protecting the mai...

Embodiment approach

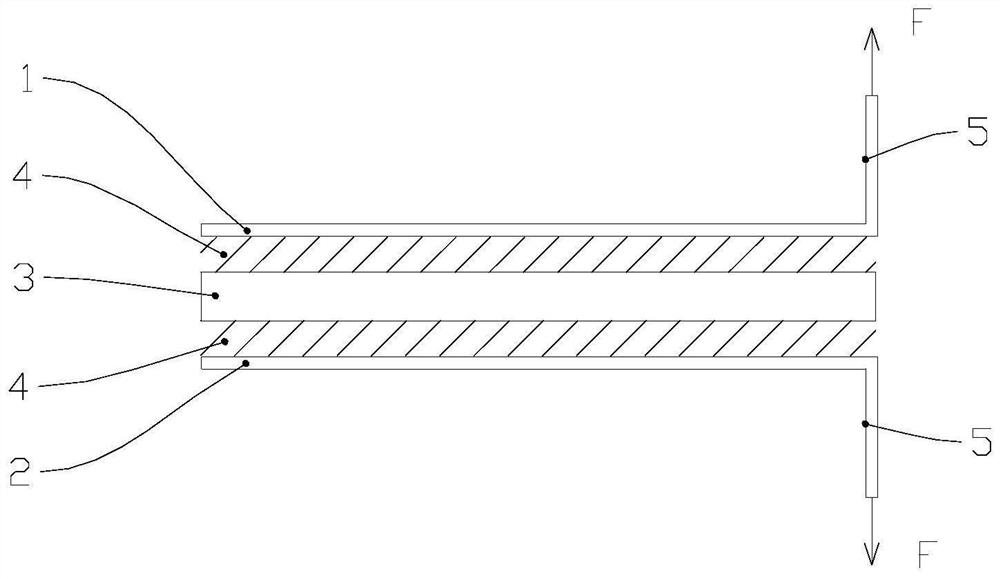

[0046] like figure 1 As shown, it shows the first embodiment in which both the first base material 1 and the second base material 2 are flexible materials. In this way, the first base material 1 and the second base material on the top and bottom layers in the figure The base material 2 is provided with a lead-out end 5, and by applying force to both, the top and bottom layers of the paper-based material body 3 are respectively subjected to forces from the top and bottom through the adhesive layer 4, thereby achieving the purpose of peeling; and During this process, due to the connection established between the first base material 1 and the second base material 2 with the paper base material main body 3 through the adhesive layer 4, the top and bottom layers of the paper base material main body 3 are stabilized, thereby avoiding Damage and breakage are avoided, and only the peeled state is achieved.

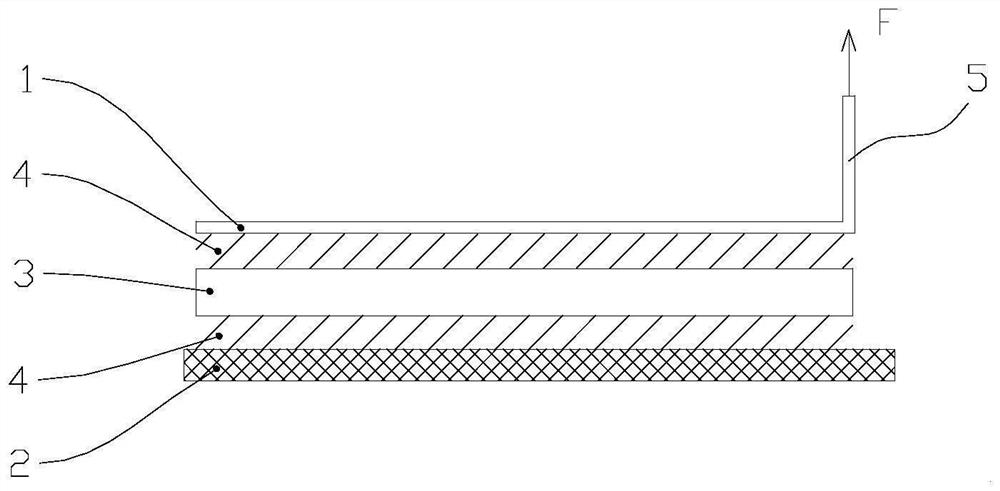

[0047] or, as in figure 2 As shown, it shows the second specific embodimen...

Embodiment 2

[0056] The method for making a sample for the peel strength test of the paper-based material comprises the following steps: respectively covering the first base material 1 and the second base material 2 on both sides of the paper-based material main body 3; The adhesive establishes respectively the connection of the first base material 1 and the paper base material main body 3, and the connection of the second base material 2 and the paper base material main body 3; Cutting with the second base material 2 to obtain a sample of required size.

[0057] Wherein, at least one of the first base material 1 and the second base material 2 is a flexible material, and the flexible material is drawn out relative to the edge of the paper base material main body 3 to form a force application position during the test.

[0058] As described in the above-mentioned embodiment, the adhesive can be purchased from the adhesive tape, and in this way, the part where the flexible material is led out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com