Glue spraying gun special for gluing

A glue gun and glue gun technology, applied in the field of glue gun, can solve the problems of high cost and price, different structures, inconvenient use, etc., and achieve the effects of reducing labor costs, ensuring life, and reducing shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

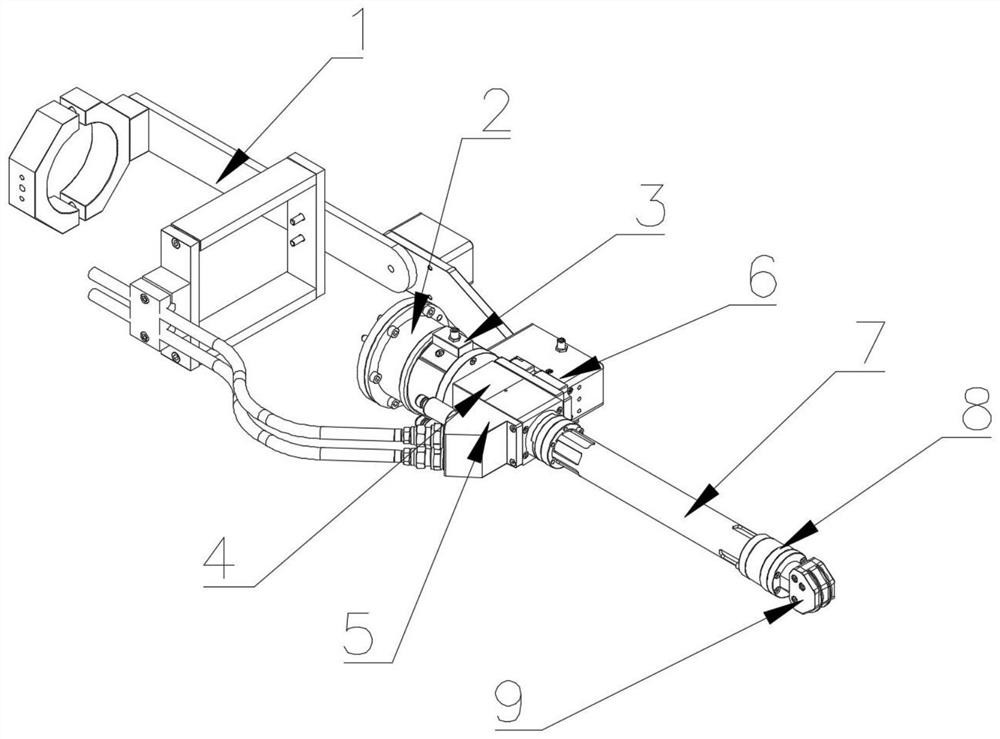

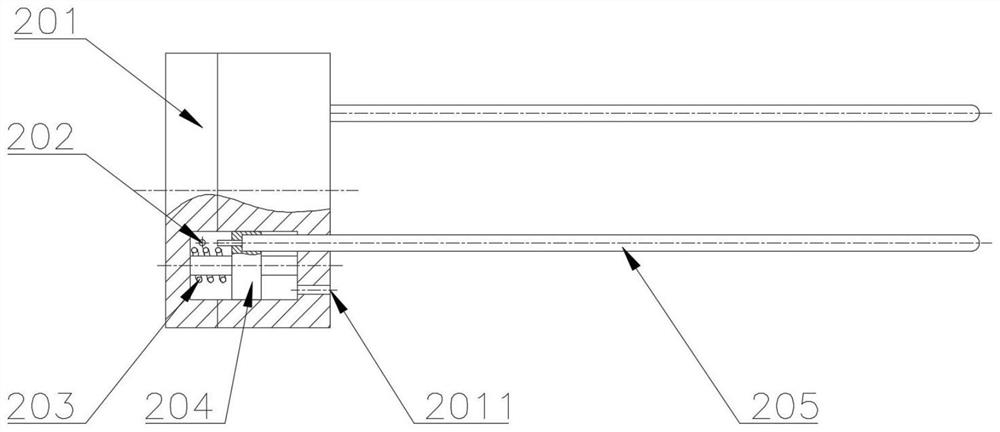

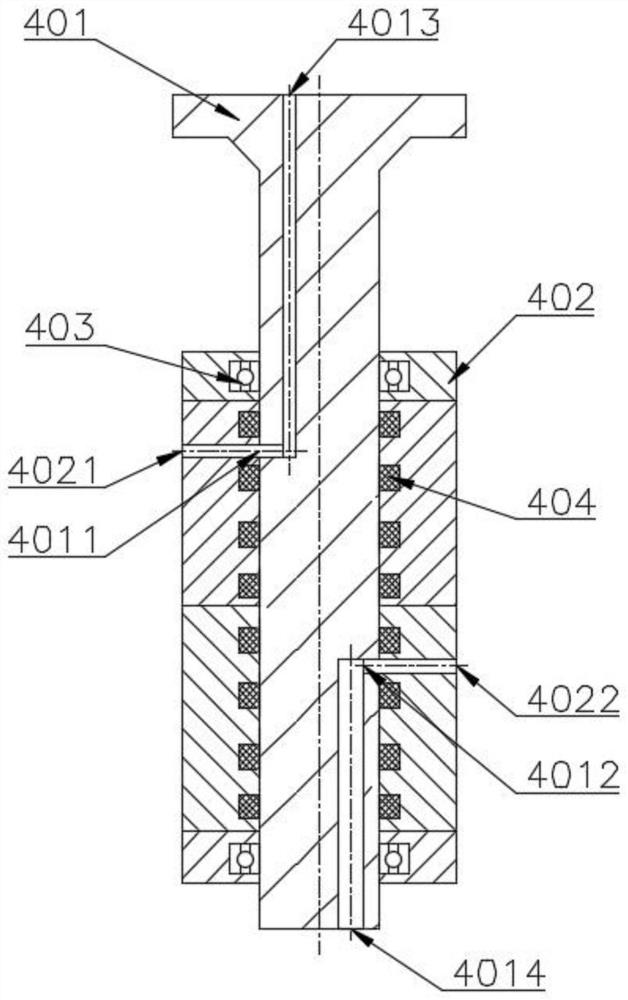

[0024] Example 1: See Figure 1-3 , the present invention provides a technical solution: a special spray gun for gluing, including a glue gun connecting bracket 1, a control valve group unit 2, a slip ring unit 3, a glue gun rotation unit 4, a glue supply unit 5, and a solenoid valve group Unit 6, glue gun connecting pipe unit 7, valve seat unit 8 and nozzle unit 9, control valve group unit 2 is arranged on the glue gun connecting bracket 1, glue gun rotating unit 4 includes rotating mandrel 401 and rotating chamber 402, and rotates The mandrel 401 is set through the rotating chamber 402, the rotating mandrel 401 is connected with the control valve group unit 2, the rotating chamber 402 is connected with the glue gun connecting bracket 1, the slip ring unit 3 is connected with the glue gun rotating unit 4, and is used to control the valve The sensor wiring of the group unit 2, the two sides of the control valve group unit 2 are respectively fixedly connected with the glue supp...

Embodiment 2

[0031] Example 2: See Figure 4-6 , the present invention provides a technical solution: a special spray gun for gluing, including a glue gun connection bracket 1, a glue gun rotation unit 4, a glue supply unit 5, a solenoid valve group unit 6, a glue gun connection pipe unit 7, an integrated Type cut-off valve group unit 10 and glue gun nozzle unit 9, glue gun rotating unit 4 is connected with glue gun connecting bracket 1, glue gun rotating unit 4 includes rotating mandrel 401 and rotating chamber 402, rotating mandrel 401 is arranged on rotating chamber In 402, the rotating cavity 402 is connected with the glue gun connection bracket 1, the glue supply unit 5 and the solenoid valve group unit 6 are respectively fixedly connected to both sides of the glue gun rotation unit 4, and the glue supply unit 5 is provided with a glue inlet port and Glue outlet interface, one end of the glue gun connecting pipe unit 7 is connected to the rotating mandrel 401 of the glue gun rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com