Anti-loose combined gasket and self-adaptive locking structure for rail

A technology of combining washers and locking structures, applied in the directions of rails, connecting components, locking fasteners, etc., can solve the problems of affecting the anti-loosening effect, unable to apply the nut anti-loosening requirements, unable to guarantee the anti-loosening effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

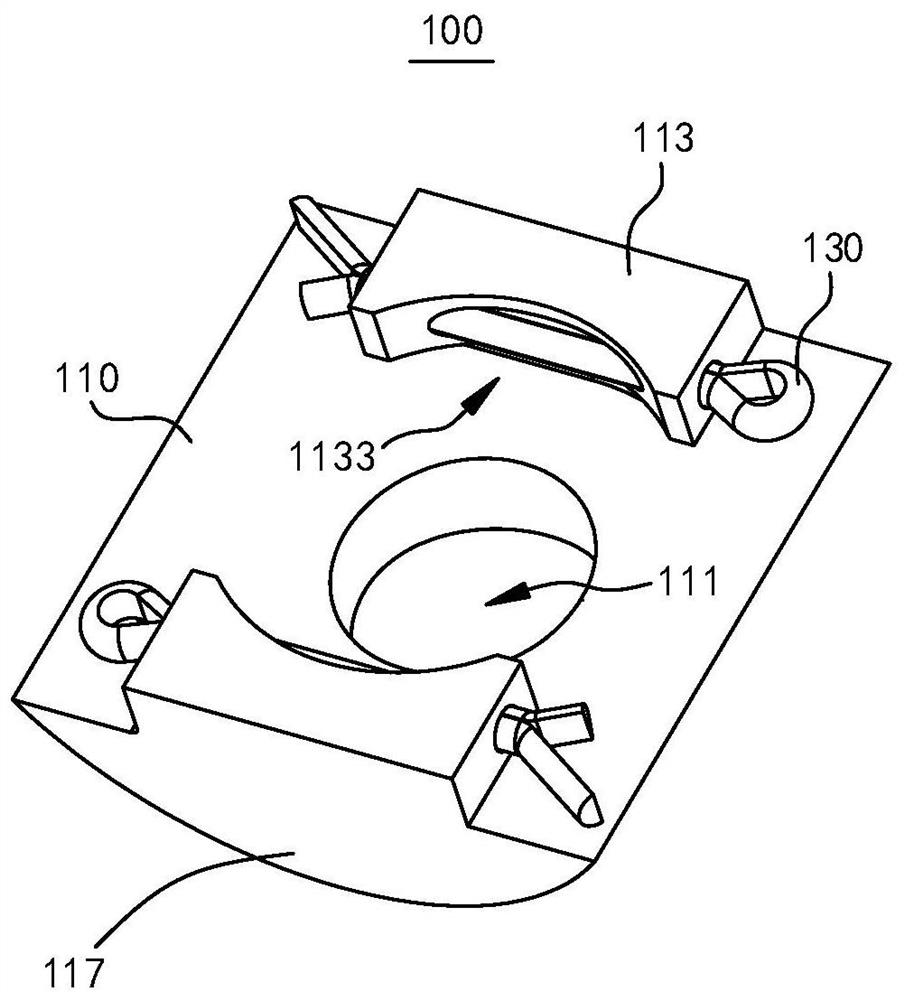

[0042] Please refer to figure 1 As shown, this embodiment provides an anti-loosening combined washer 100, which is applied to the combined locking structure of the bolt and the nut. The anti-loosening combined washer 100 can realize the anti-loosening of the nut without destroying the structure of the screw rod and the nut. And it can meet the occasions where standard bolts for various industries can effectively prevent nuts and bolts from loosening without additional processing.

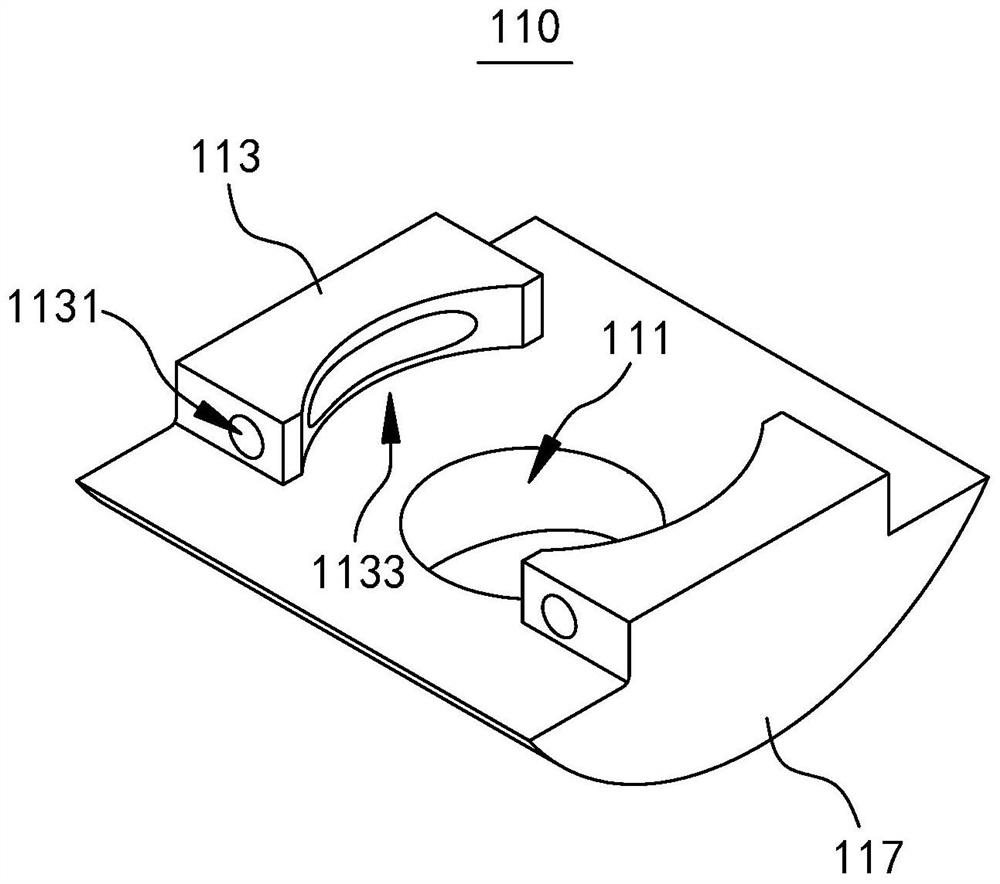

[0043] figure 2 Shown is a schematic structural view of the anti-loosening combination washer 100 provided in this embodiment in practical application, image 3 Shown is a schematic structural diagram of the washer body 110 of the anti-loosening combination washer 100 provided in this embodiment, please combine figure 2 and image 3 shown.

[0044] The anti-loosening combined washer 100 provided in this embodiment includes a washer body 110 and a detent pin 130. The washer body 110 is provided...

no. 2 example

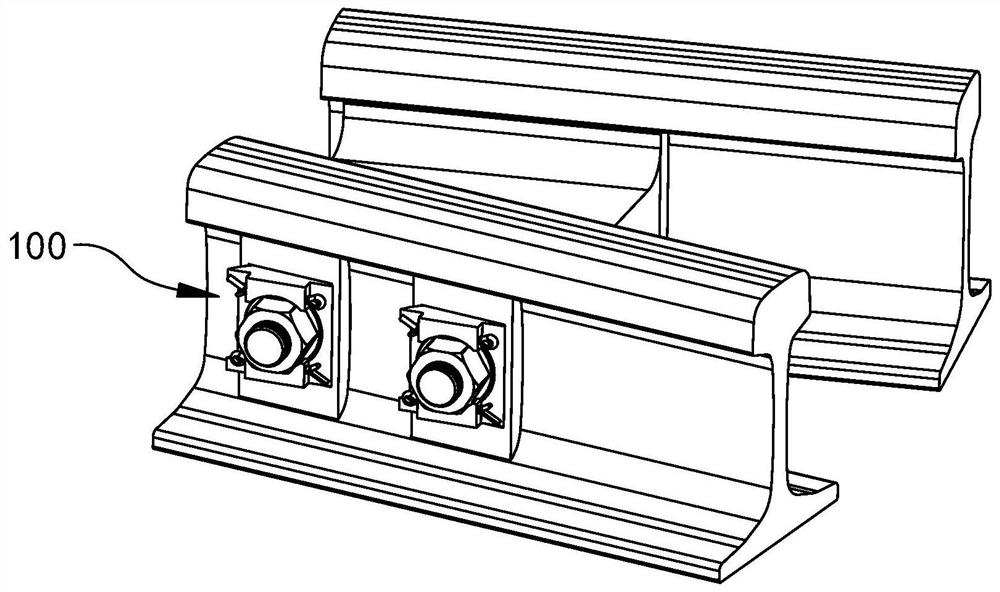

[0059] Image 6 Shown is a structural schematic diagram of the rail adaptive locking structure 200 provided by the second embodiment of the present invention in practical application, please refer to Image 6 shown. The self-adaptive locking structure 200 for a rail provided in this embodiment is applied to rail locking, and can achieve the purpose of automatic leveling and preventing nuts from loosening.

[0060] The self-adaptive locking structure 200 for the rail includes a first base 210 and the anti-loosening combination washer 100 provided in the first embodiment, Figure 7 Shown is a schematic structural diagram of the first base 210 of the rail adaptive locking structure 200 provided by the second embodiment of the present invention, please combine Image 6 and Figure 7 shown.

[0061] The first base 210 is provided with a second through hole 211 for the screw to pass through. The first base 210 is provided with a first semi-cylindrical cavity 213 on the end wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com