Automatic positioning type executing mechanism

An actuator and automatic positioning technology, applied in the field of automatic positioning actuators, can solve the problems of bloated equipment occupying production sites, affecting product preparation efficiency, increasing preparation costs, etc., to reduce settings, reduce production costs, and improve versatility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

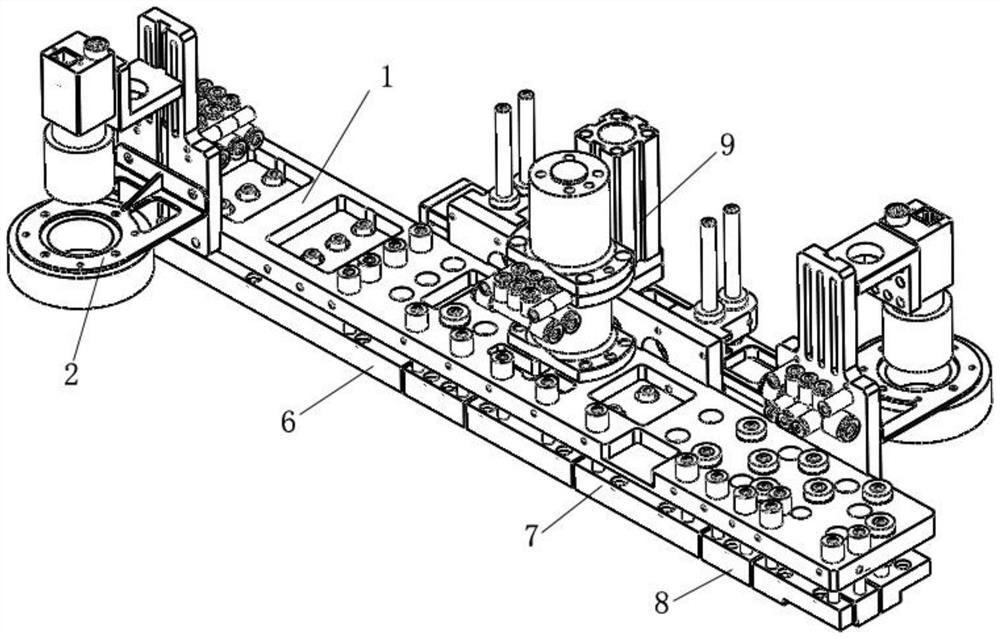

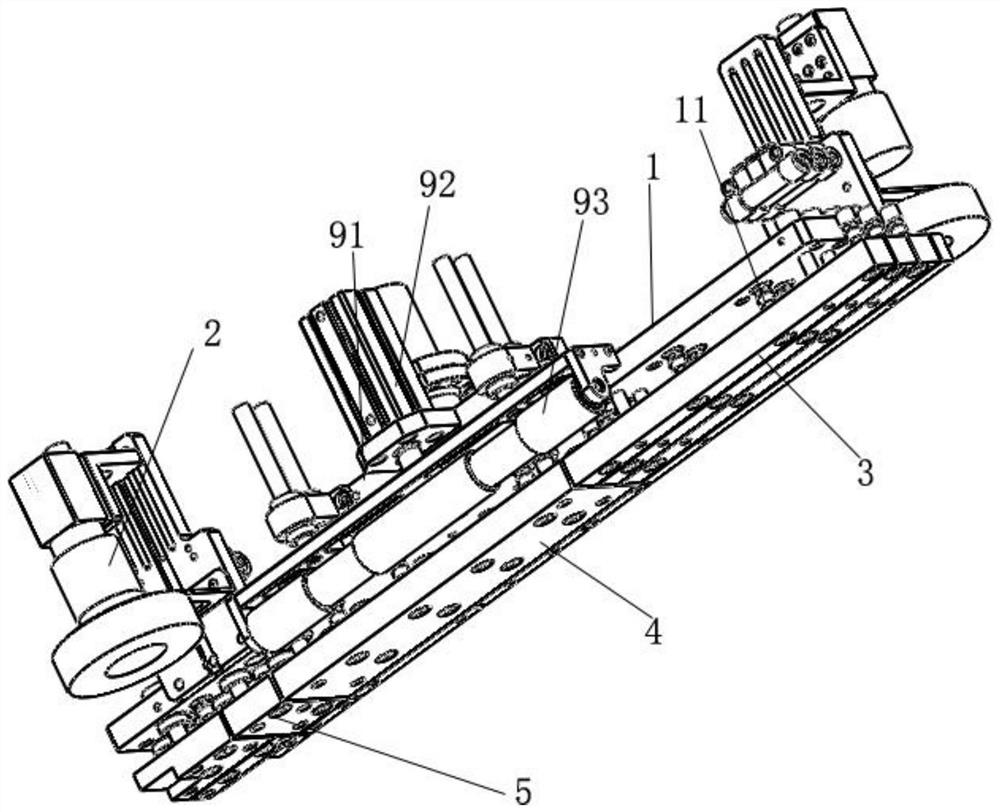

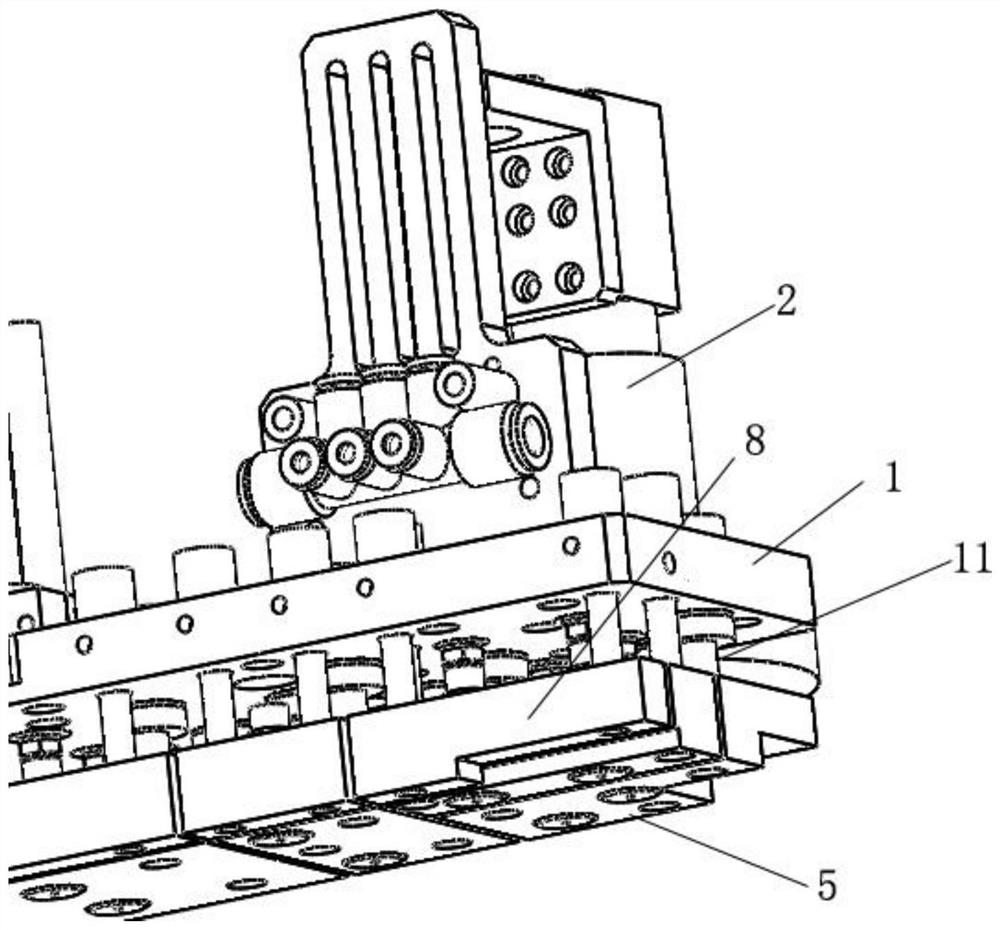

[0027] refer to Figure 1-4 , this embodiment shows an automatic positioning type actuator, including a substrate 1, edge positioning components 2 are respectively arranged on both sides of the substrate 1, and several actuators are respectively connected to the bottom of the substrate 1 through elastic connectors 11;

[0028] When the instruction is executed, the substrate 1 is moved to the corresponding product position through an external drive, and the corresponding positioning of one side edge is performed through the edge positioning component 2 on one side, and the start bit is recorded, and the rear substrate 1 is positioned by the external drive. The pressing down command is connected to the substrate 1 through a number of actuators through the elastic connector 11 to form a flexible pressing down execution structure that avoids damage to the product surface; The side edge positioning component 2 locates the edge of the other side of the product, and completes the exe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap