Rotary feeding articulated chute

A rotary feeding and chute technology, applied in the metallurgical field, can solve the problem of low service life of the rotary feeding chute, and achieve the effect of increasing the heat insulation and dust protection cover, reasonable design and improving the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

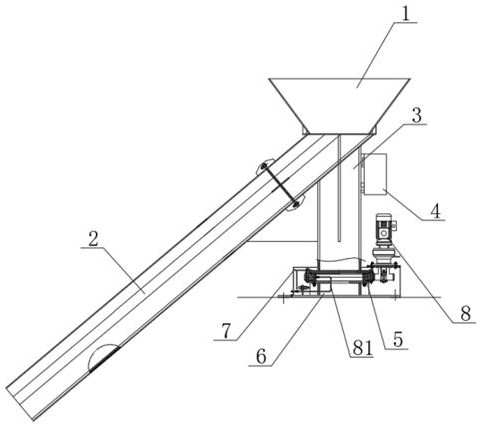

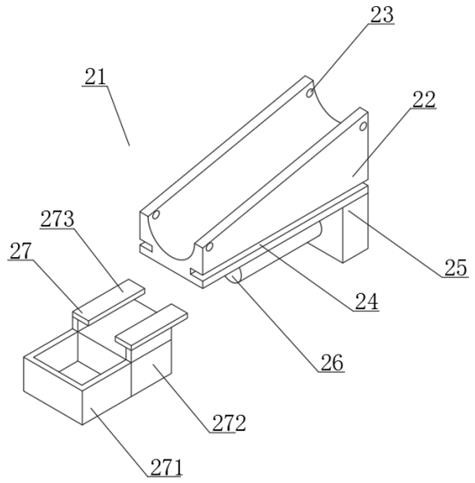

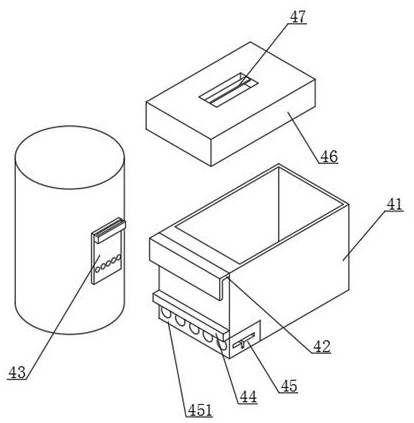

[0030] Refer to attached Figure 1-4 , a rotary feeding chute, comprising a feeding funnel 1, the bottom of the feeding hopper 1 is connected to a discharging chute 2, the bottom of the discharging chute 2 is provided with a rotating column 3, and the outlet of the rotating column 3 The symmetrical side of the material chute 2 is detachably connected to the adjustable counterweight device 4, the bottom of the rotating column 3 is provided with a slewing support 5 with external teeth, and the slewing support 5 with external teeth is arranged on a base 6, and the base 6 A heat-insulating and dust-proof protective cover 7 is provided on the side facing the molten steel, and the other side of the base 6 is connected to the driving device 8. The application can level the device through the adjustable counterweight device 4 on the side, so as to ensure that the rotating column 3 on the top The side weight level improves the service life of the rotating column 3, and the eccentric bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com