Tubular pile sinking test device

A test device and pile sinking technology, which is applied in the test of foundation structure, sheet pile wall, building, etc., can solve the problems that the pile foundation deviates from the vertical direction, cannot ensure the seamless contact of the observation window of the model pile, and the test results are inaccurate, etc. , to achieve the effect of ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

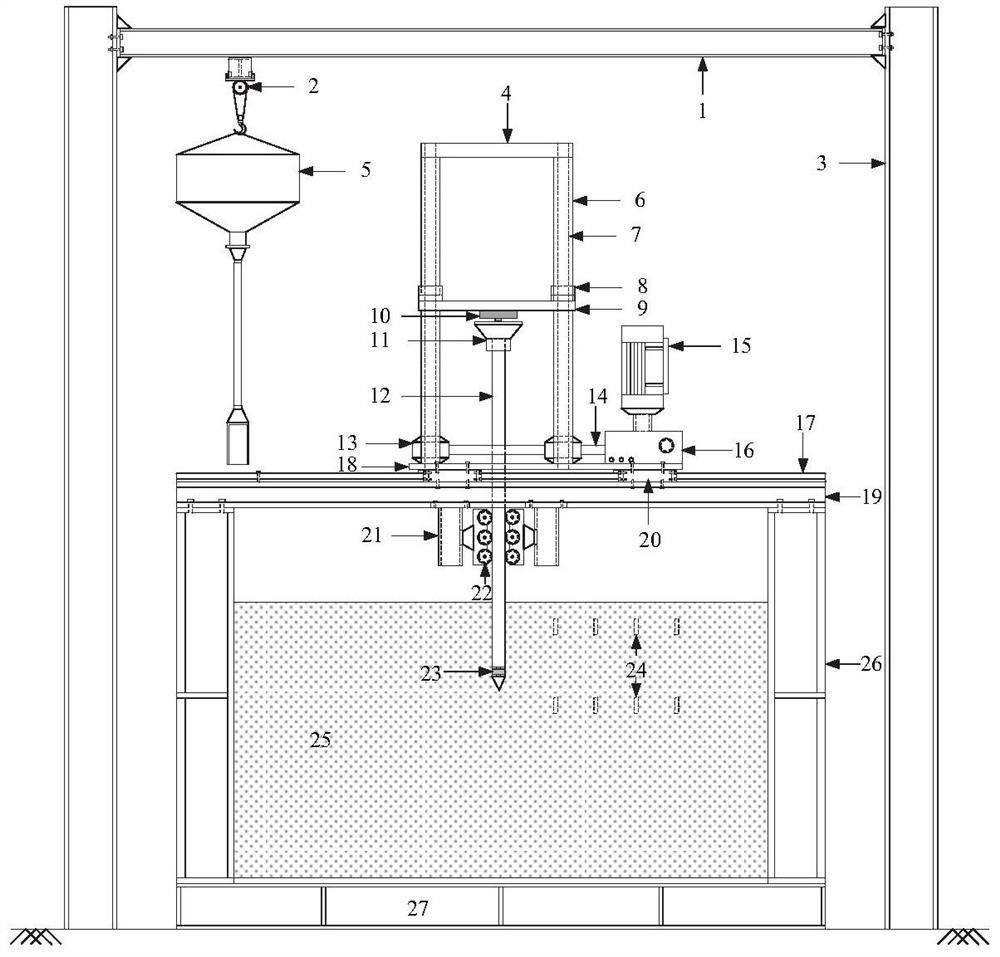

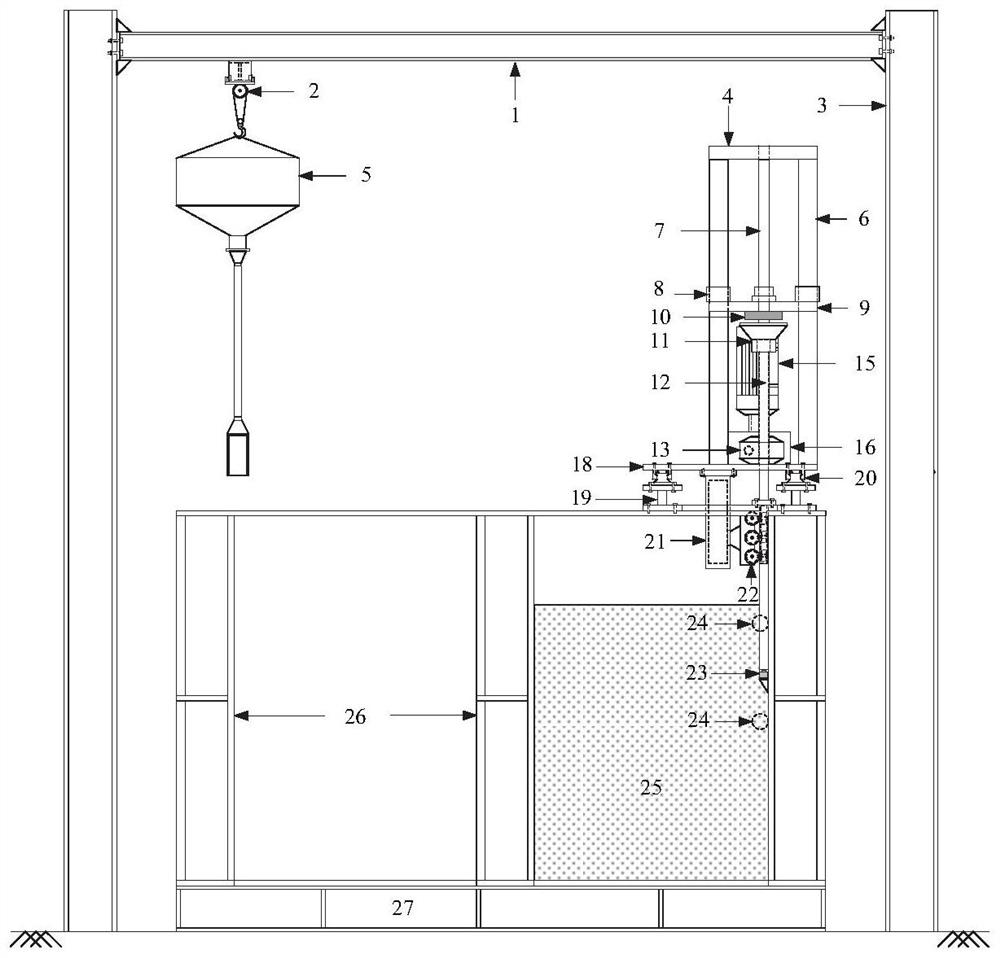

[0027] A pile sinking test device for pipe piles, including a model tank for holding sand samples. In this embodiment, the model tank adopts a cubic structure with an open top, including four side tank walls 26, and four side tank walls. The wall of the tank is fixed on the base 27 by bolts.

[0028] In order to realize the visualization of the pile sinking test, in this embodiment, the side wall of the model tank is made of transparent tempered glass.

[0029] In one embodiment, according to actual needs, the length, width, and height of the model groove are 1.5m, 1.5m, and 1.2m respectively, and the thickness of the transparent tempered glass is 19mm. It can be understood that it can be set according to actual needs. Dimensions of the model slot and its side slot walls.

[0030] The top of the model groove is provided with a support member, and a vertical displacement drive mechanism for driving the model pile to move vertically is installed on the support member. The verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com