Lifting driving mechanism and lifting system for high-barrier truck canopy

A technology of lifting drive mechanism and lifting system, which is applied in the direction of freight vehicles, motor vehicles, load coverage, etc., and can solve problems such as not in place, manual moving, unsafe operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The principles and features of the present invention are described below in conjunction with examples, which are only used to explain the present invention and are not intended to limit the scope of the present invention.

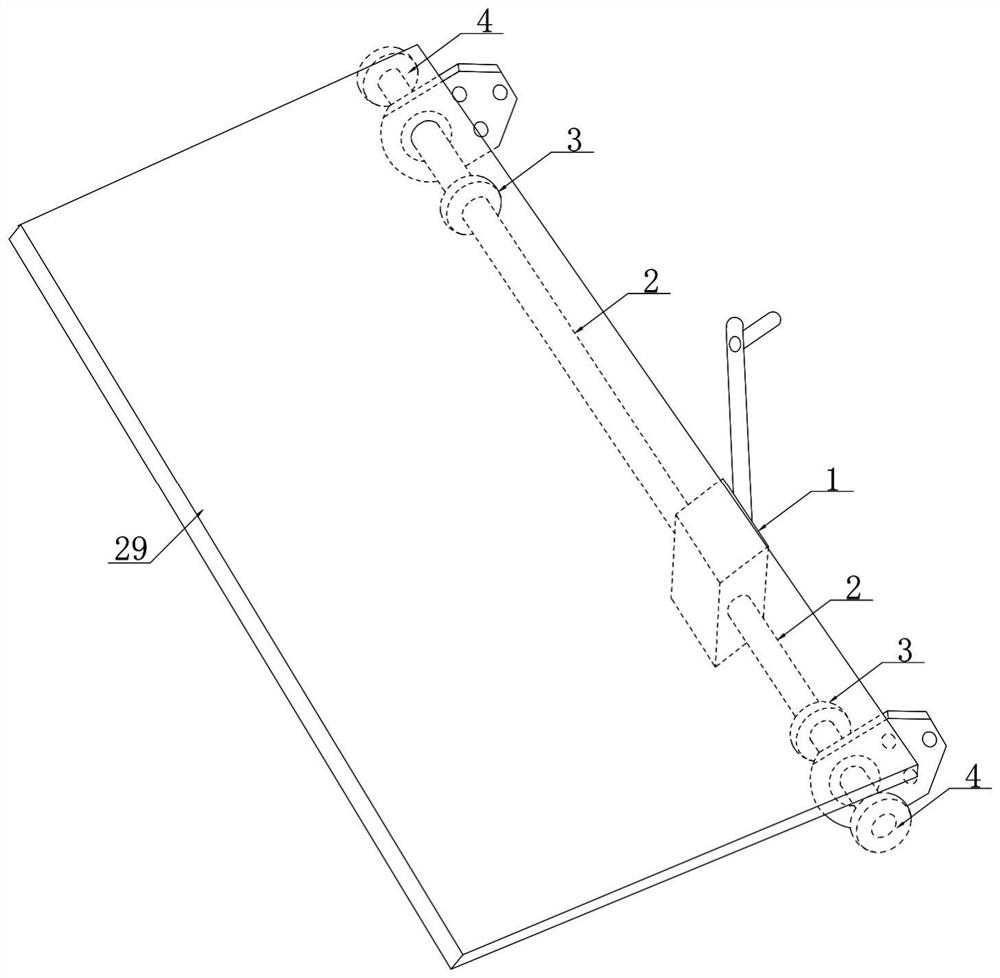

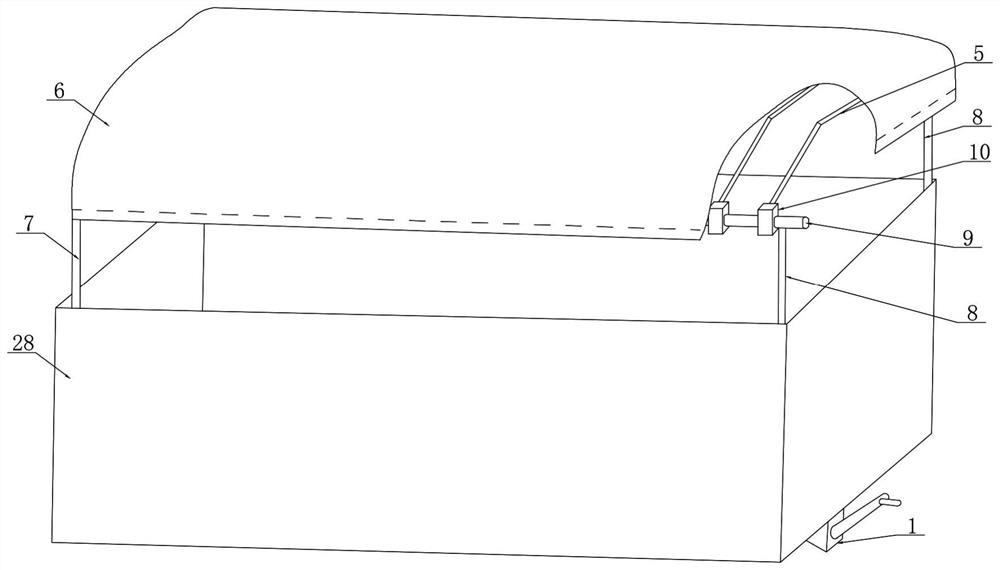

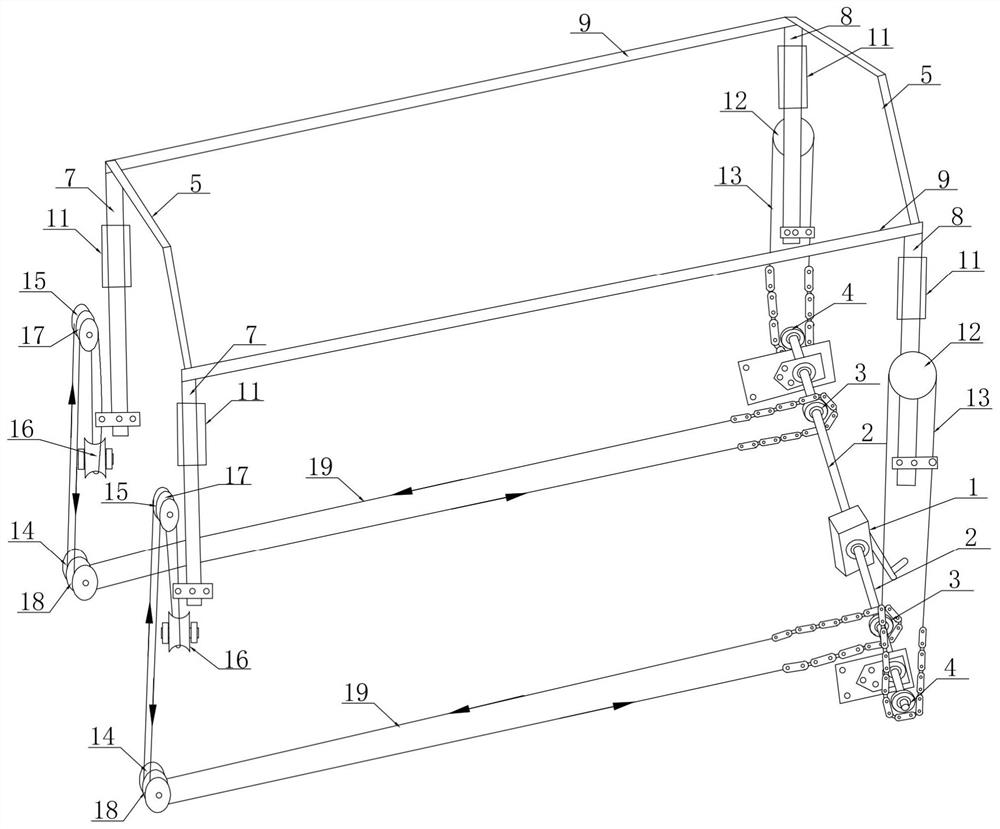

[0039] Such as figure 1 As shown, a high rail truck cover lifting drive mechanism includes a reducer 1, a drive shaft 2 and two sets of drive sprockets, the drive shaft 2 is connected to the output end of the reducer 1, and the two sets of drive sprockets The sprockets are respectively arranged on the drive shafts 2 on the left and right sides of the reducer 1. The high-rail truck includes a compartment 28, and the compartment includes a bottom plate 29. The drive shaft is rotatably arranged on the drive shaft 2. The bottom of the base plate, the drive sprocket includes a front drive sprocket 3 and a rear drive sprocket 4.

[0040] The speed reducer 1 adopts a hand-operated speed reducer 1 . The operator can shake the reducer 1 with one hand to con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com