Ink detection system for digital printing and use method

A detection system and digital printing technology, applied in the direction of material inspection products, etc., can solve the problems of plate cylinder wetting deterioration, ink concentration data errors, ink chambers are prone to foam, etc., to improve efficiency and accuracy, and increase the scope of application , avoid the effect of collision and dumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

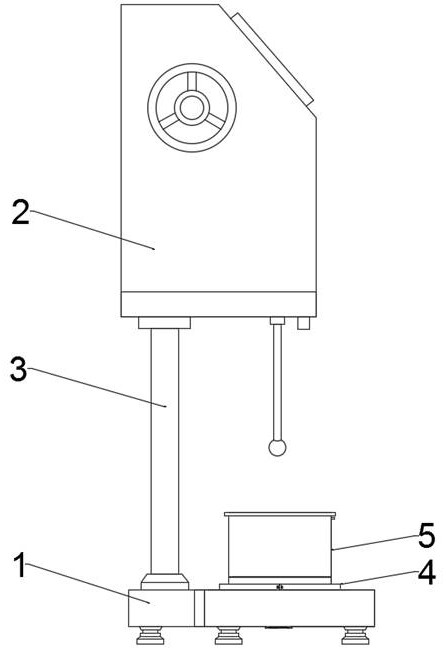

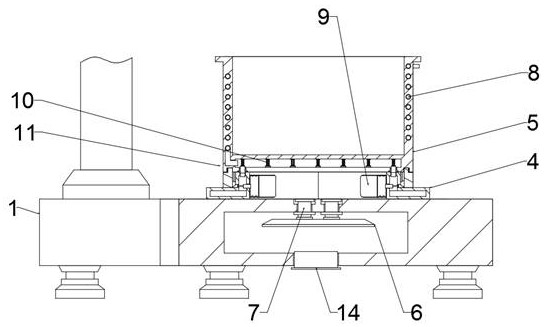

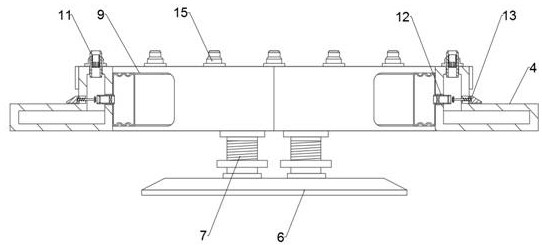

[0032] Example: see Figure 1-8, an ink detection system for digital printing, comprising a base 1, an ink concentration detector 2 arranged above the base 1, and a column 3 fixed to the bottom of the ink concentration detector 2 and the top side of the base 1, the top surface of the base 1 Both sides of the middle part are equipped with a semicircular plate-shaped mounting seat 4, and the cross section of the mounting seat 4 is L-shaped. The support box 5 is installed on the top of the mounting seat 4; the inside of the base 1 is provided with an air supply chamber; the inner arc surface of the mounting seat 4 is provided with an airbag pad 9, and the inside of the two mounting seats 4 is provided with a communicating cavity. The top of 4 is equidistantly provided with a number of threaded holes, and fixed pipes 11 are arranged in the threaded holes; connecting pipes 12 connected with the airbag cushion 9 are transversely penetrating through the inner walls of both sides of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com