Scram button protection cover and use method

A protective cover and button technology, which is applied in the field of transportation, can solve the problems such as difficult to open the protective cover, stop driving, and difficult to press the emergency stop button in time, so as to prevent it from being difficult to open and improve the firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] like Figure 1 to Figure 4 Shown:

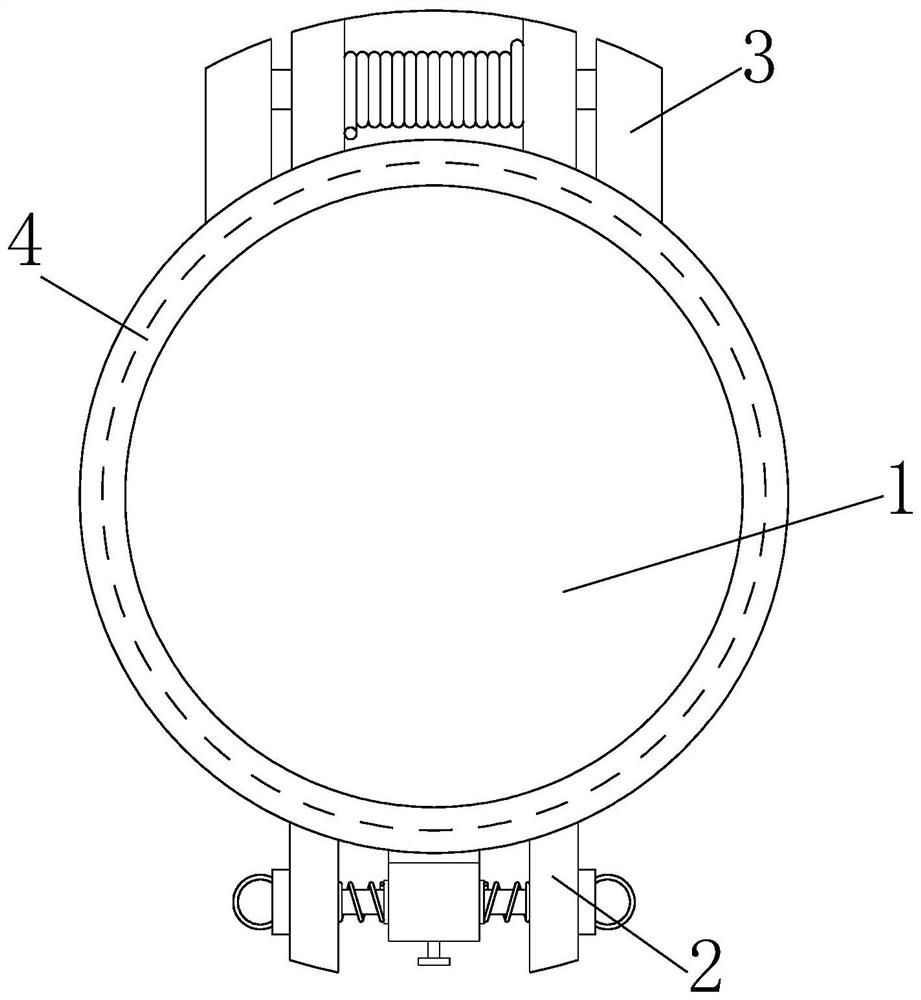

[0036] A protective cover for an emergency stop button, which is arranged outside the emergency stop button X, and includes a top cover 1, a clamping plate 2 and a protection mechanism 4;

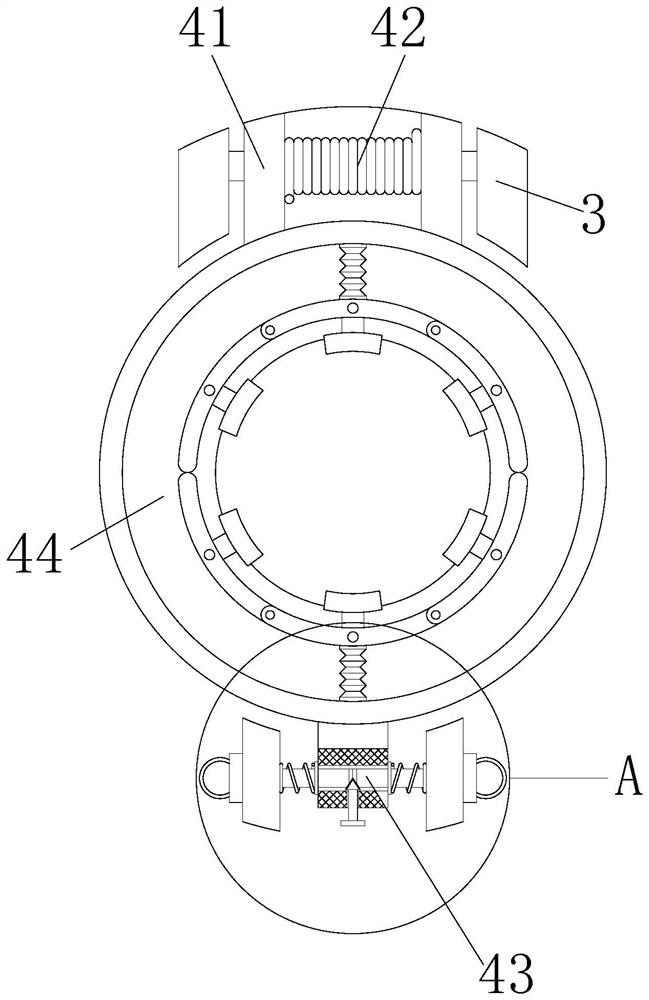

[0037] The protection mechanism 4 includes a protection frame 441 and an engaging mechanism 43; the protection frame 441 is cylindrical and hollow inside, and is vertically sleeved outside the emergency stop button X. Side; the engaging mechanism 43 is connected to the protective frame 441 , and the engaging mechanism 43 is arranged on the protective frame 441 between the two clamping plates 2 .

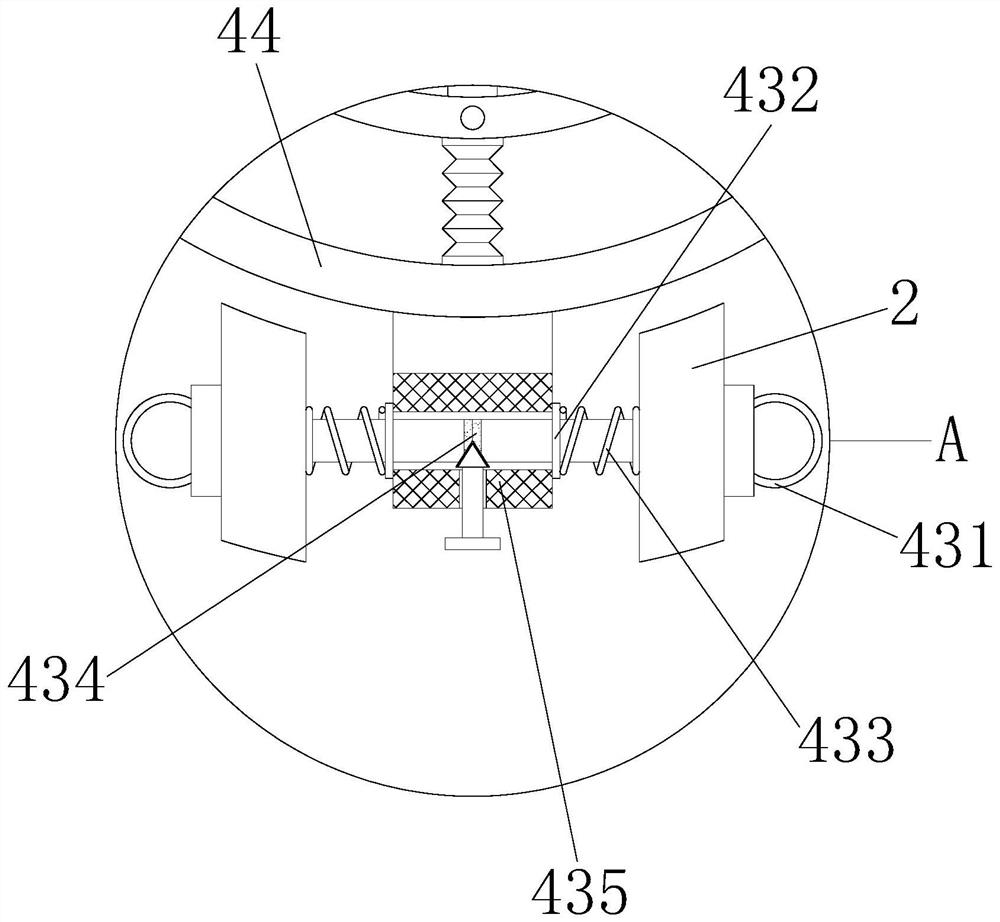

[0038]Engagement mechanism 43 comprises pull bar 431, spacer 432, spring 433, magnetic sheet 434 and separating mechanism 435; Pull bar 431, spacer 432, spring 433 and magnetic sheet 434 are all provided with two, are left-right symmetrical structure; A tie rod 431 runs through a clamping plate 2, a limiting piece 432 is welded to the middle end of a pu...

Embodiment 2

[0046] Such as Figure 5-6 As shown, on the basis of Embodiment 1, a nesting mechanism 44 is also included. The nesting mechanism 44 includes a telescopic hose 442 and a conflicting mechanism 443. The conflicting mechanism 443 includes a connecting plate 43a and a buckling plate 43c; the telescopic hose 442 and the interference mechanism 443 are two, symmetrically arranged inside the protective frame 441; one end of the telescopic hose 442 is connected to the inner wall of the protective frame 441, and the other end is connected to the connecting plate 43a, and the connecting plate 43a and the fastening plate 43c are arc-shaped plates , the height of the fastening plate 43c and the connecting plate 43a is greater than the rebound height of the emergency stop button X, and the fastening plate 43c is arranged on the inner wall of the connecting plate 43a. The bottom of the connecting plate 43a is provided with a slider, and the inner bottom of the protection frame 441 is provide...

Embodiment 3

[0051] Such as Figure 7 As shown, the resistance mechanism 443 also includes a push force mechanism 43d, which is arranged at the bottom of the emergency stop button X, and the push force mechanism 43d includes a spring rod d2, which has contractility, and there are multiple spring rods d2, which are arranged symmetrically on the inner bottom surface of the protective frame 441 .

[0052] The jacking mechanism 43d also includes a support plate d1, a top sheet d3 and a rubber pad d4; the support plate d1 is connected to the inner wall of the connecting plate 43a below the emergency stop button X, the support plate d1 is parallel to the emergency stop button X, and the spring rod d2 runs through the support plate d1, the upper end of the support plate d1 is provided with a top piece d3, and a rubber pad d4 is pasted on the top piece d3. The rubber pad d4 has a wrinkled structure and has a certain resilience, so as to improve the resilience of the bottom of the emergency stop b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com