Hot air type automobile leather deodorizing equipment and method

A technology for leather and automobiles, which is applied in the field of hot air deodorization equipment for automobile leather. It can solve the problems of single deodorization method, unfavorable fast deodorization, and inability to completely solve the leather odor, and achieve a good deodorization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

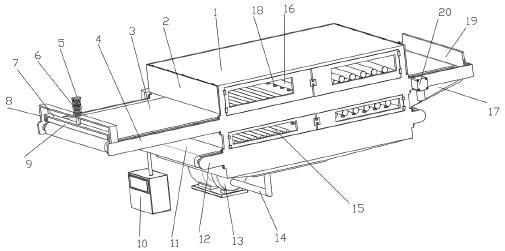

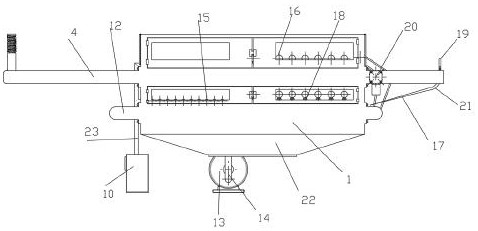

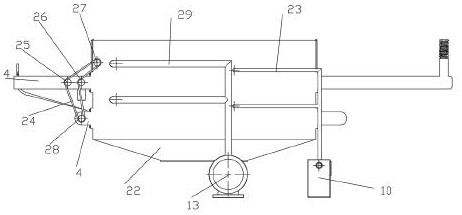

[0034] Such as figure 1 As shown, a hot air type automobile leather deodorization equipment includes a deodorization box 1, the deodorization box 1 is hinged to rotate with a door panel, and the door panel is provided with a glass window, and the two ends of the deodorization box 1 are hinged to have a cover plate 2, The feeding end of the deodorizing box 1 is provided with a feeding and pressing structure, and the feeding and pressing structure includes a pull plate 5, a spring 6, a connecting seat 7, a supporting seat 8 and a pressure roller 9, and the top of the supporting seat 8 is fixed with a spring 6, a spring 6. The top is connected with a pull plate 5, and the bottom of the pull plate 5 runs through the support base 8 and is connected with a connection base 7. The upright inner wall of the connection base 7 rotates through a bearing to form a support base 8.

[0035] The spring 6 of the feeding and pressing structure drives the pull plate 5 to move downward, the pull ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com