Gear linkage structure for compressor, compressor, outdoor unit and air conditioning system

A technology of gear linkage and compressor, applied in air-conditioning systems, compressors, machines/engines, etc., can solve the problem that the compressor cannot realize one-way operation, and achieve the effects of improving lifespan, reducing costs and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

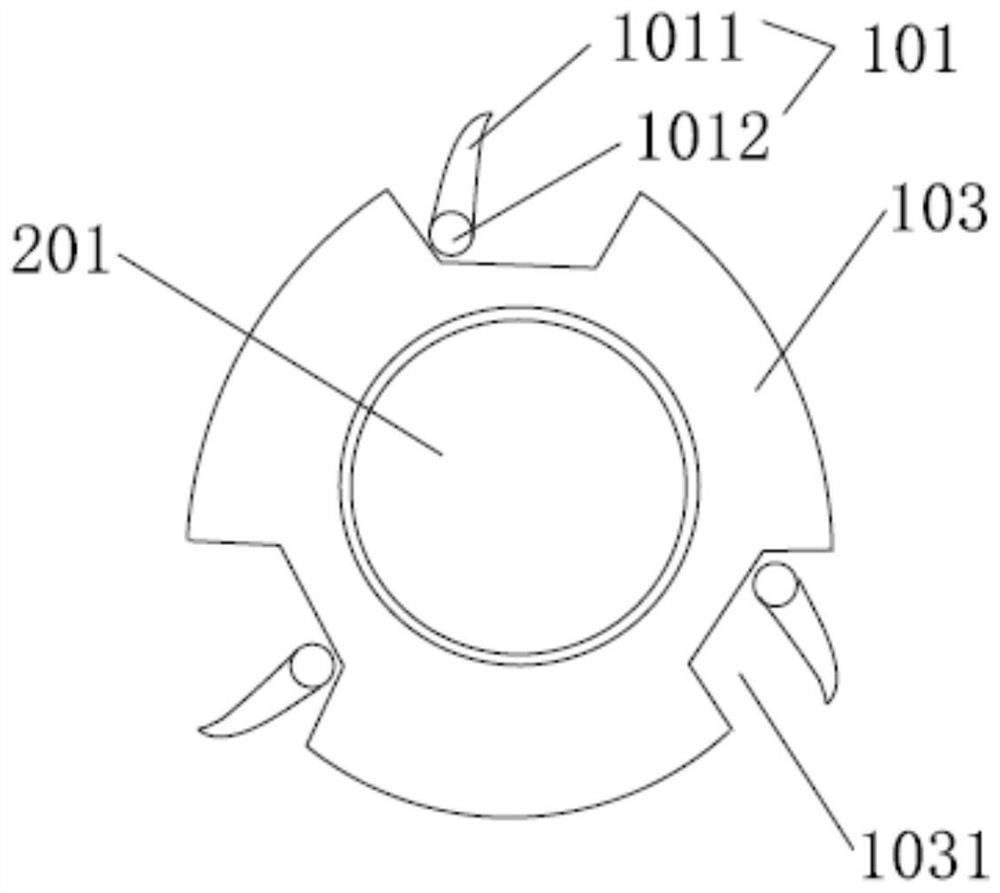

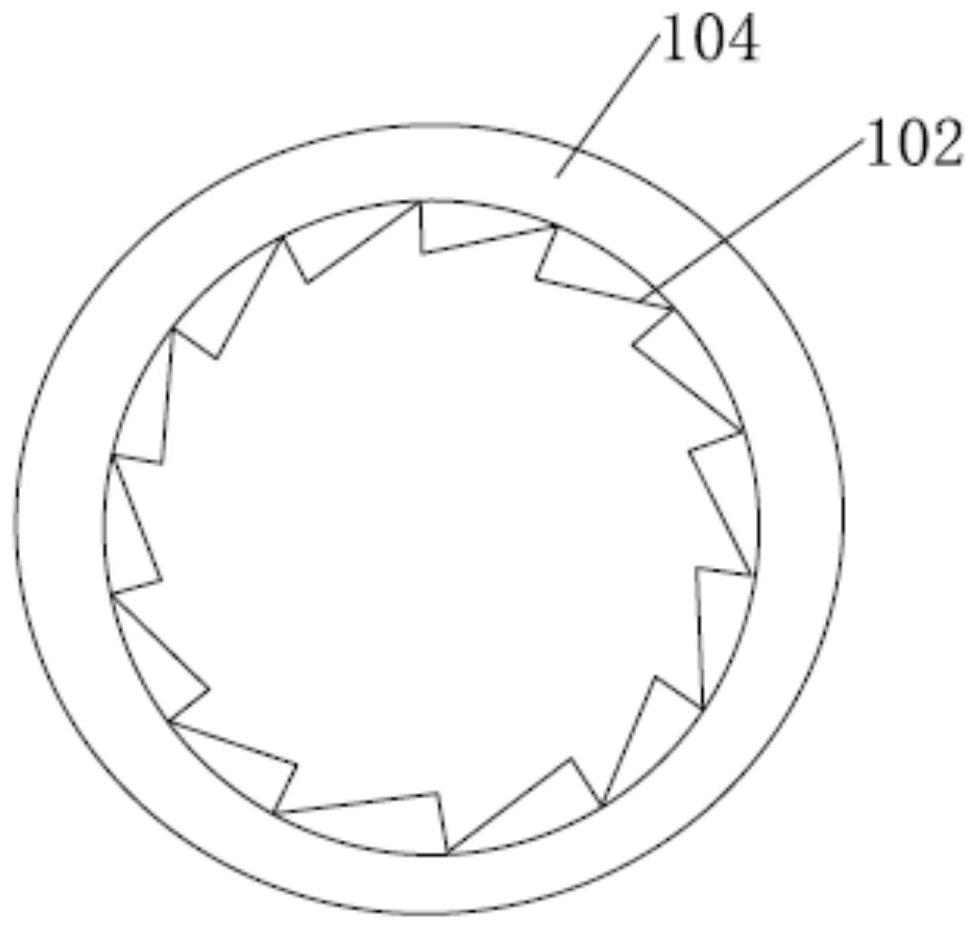

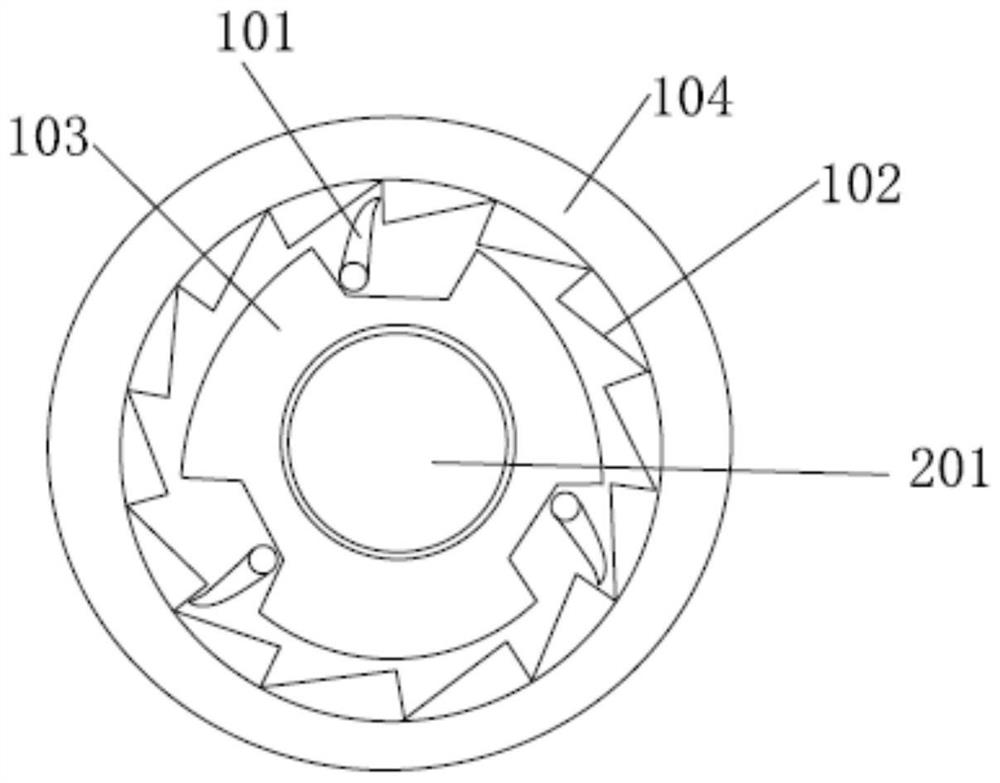

[0045] This embodiment describes in detail the gear linkage structure used in the compressor of the present invention.

[0046]This embodiment is used for the gear linkage structure of the compressor, including the jack assembly 101 and the gear 102, such as Figure 1~3 shown. Preferably, the jack assembly 101 is connected to the first shaft 201 of the compressor and makes the steering of the jack assembly 101 consistent with the steering of the first shaft 201, and when the motor drives the first shaft 201 to rotate forward, the jack assembly 101 rotates forward and pushes the gear 102 drives the compressor body to rotate forward; when the motor drives the first rotating shaft 201 to reverse, the jack assembly 101 reverses and receives the pressure of the gear 102. The force required to rotate, the compressor body remains static, such as Figure 1~3 shown. The forward rotation mentioned in this embodiment may be clockwise rotation, correspondingly, reverse rotation is coun...

Embodiment 2

[0061] This embodiment describes the compressor of the present invention in detail.

[0062] The compressor in this embodiment includes a compressor body and a gear linkage structure. Preferably, the gear linkage structure is the gear linkage structure used in any one of the technical solutions in Embodiment 1 for the compressor. The structure of the compressor body can be the same as that of the prior art, and will not be repeated here.

[0063] The compressor of this embodiment includes any one of the technical solutions in Embodiment 1 for the gear linkage structure of the compressor. Through the action of the gear linkage structure, the compressor body can realize one-way operation, avoiding the reverse rotation of the compressor The resulting wear and tear of parts improves the reliability of the compressor operation, improves the service life and environmental tolerance of the compressor, cancels the anti-reverse protection measures of the compressor, and reduces the co...

Embodiment 3

[0065] This embodiment describes the outdoor unit of the present invention in detail.

[0066] The outdoor unit of this embodiment includes an outdoor unit body and a compressor. Preferably, the compressor is the compressor of any one of the technical solutions in Embodiment 2. The structure of the outdoor unit body can be the same as that of the prior art, and will not be repeated here.

[0067] The outdoor unit of this embodiment includes the compressor of any one of the technical solutions in Embodiment 2. Through the function of the compressor, the reliability of the operation of the outdoor unit can be improved, the life of the outdoor unit can be increased, and the cost of the outdoor unit can be reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com