Roller cleaning device with automatic regulation and control function for conveying roller way

A function and roll cleaning technology, which is applied in the field of aluminum processing hot rolling mill roller table cleaning, can solve the problems of high labor cost, uncoordinated width, and affecting equipment use, and achieve the effects of reducing manpower input, improving safety, and facilitating adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

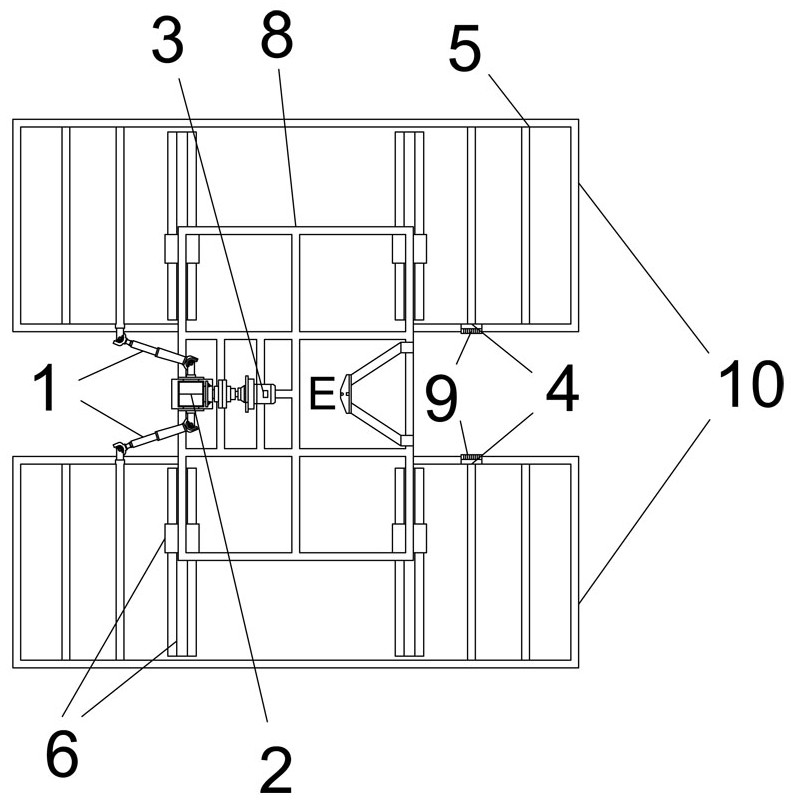

[0048] like Figure 1 to Figure 8 As shown in the figure, a roller cleaning device for a conveying roller table with automatic regulation function includes a transporting bracket 8, the transporting bracket 8 is a square frame structure, one end of the transporting bracket 8 is provided with a regulating device, and two parts of the transporting bracket 8 are provided There is a roller cleaning mechanism on the side;

[0049] The roller cleaning mechanism includes a frame 10 and a reel 4 arranged on the frame 10. The reel 4 includes an unwinding shaft 401 and a winding shaft 402, and the unwinding shaft 401 and the winding shaft 402 are respectively arranged on both sides of the frame 10. , a cleaning roll is wound between the unwinding shaft 401 and the winding shaft 402, and the cleaning roll is exported from the unwinding shaft 401, wraps the bottom surface of the frame 10 and is connected with the winding shaft 402;

[0050] The control device includes a drive motor 3, a do...

Embodiment 2

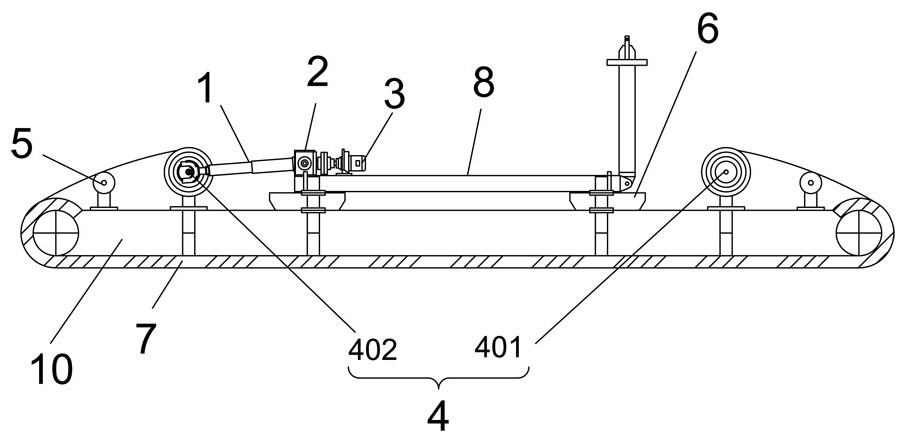

[0056] The cleaning mechanism is optimized to increase the smoothness of the cleaning process:

[0057] like figure 2 As shown, the rear side of the unwinding shaft 401 and the front side of the rewinding shaft 402 are symmetrically provided with deflector rollers 5 along the center line of the frame 10. The deflector rollers 5 are used to limit the cleaning roll, and the deflector rollers 5 The two ends of the unwinding shaft 401 and the winding shaft 402 are respectively provided with brackets. The deflecting roller 5 , the unwinding shaft 401 and the winding shaft 402 are rotatably connected with the brackets, and the brackets are fixedly connected with the frame 10 .

[0058] The frame 10 is a square frame, and the two ends of the frame 10 are column-shaped strips. The bottom of the frame 10 is provided with a felt pad 7 for increasing friction. The felt pad 7 is fixed to the bottom surface and both ends of the frame 10. The pad 7 is arranged on the inner side of the cle...

Embodiment 3

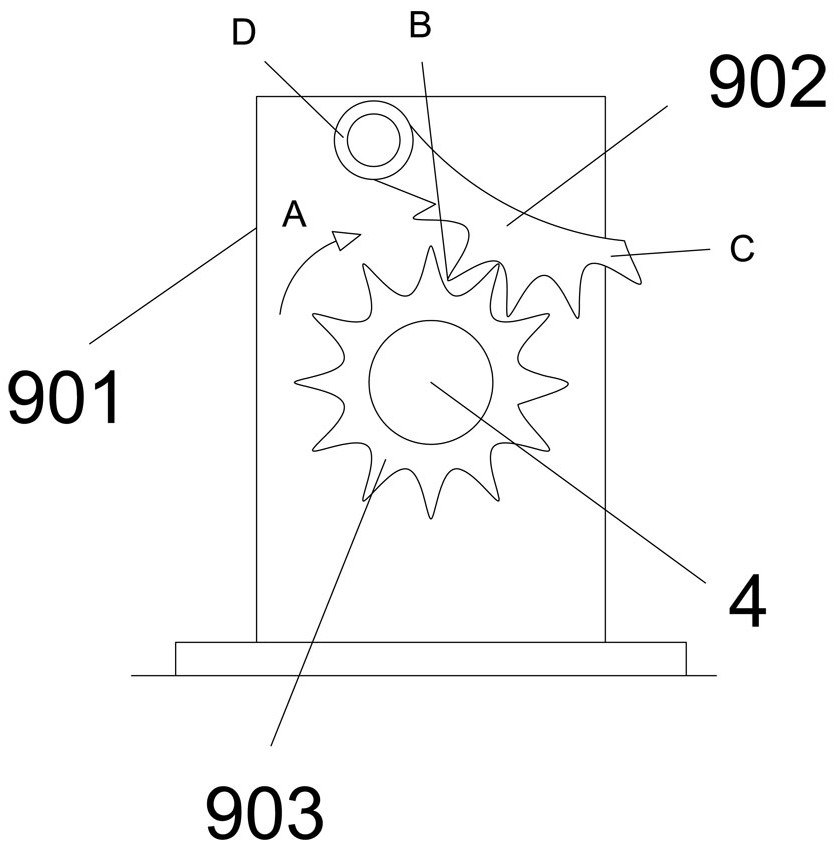

[0061] In order to avoid the confusion of the cleaning position of the cleaning roll caused by the two-way movement, set the limit device 9:

[0062] The unwinding shaft 401 and the rewinding shaft 402 are both provided with a one-way limit device 9, the one-way limit device 9 includes a connecting plate 901 and a gear mechanism, the gear mechanism includes a limit card 902 and a gear 903, the The gear 903 is respectively fixed with the unwinding shaft 401 and the winding shaft 402, the limit card 902 is rotatably connected with the connecting plate 901, the connecting plate 901 is a square plate, and the connecting plate 901 is fixed with the frame 10;

[0063] The limit card 902 is a meniscus-shaped structure, the middle of the limit card 902 is provided with teeth, the limit card 902 meshes with the gear 903 through the teeth, and the limit card 902 limits the position when the gear 903 is reversed.

[0064] like image 3 As mentioned above, in the figure, A represents the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com