Sub-nanoscale high-precision micro-displacement device capable of being calibrated and application of sub-nanoscale high-precision micro-displacement device

A sub-nanometer, micro-displacement technology, applied in measurement devices, electrical devices, optical devices, etc., can solve problems such as not quantitative control, but staying in qualitative resolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is described in further detail with reference to the accompanying drawings and specific embodiments.

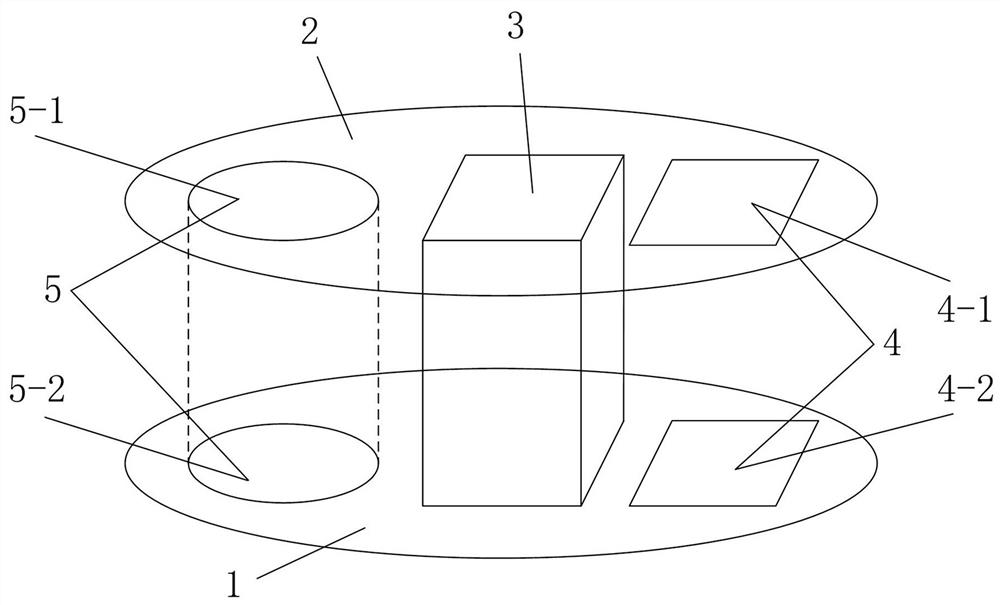

[0039] Such as figure 1 as shown, figure 1 It is a schematic diagram of a calibratable sub-nanometer high-precision micro-displacement device provided by the present invention. The high-precision micro-displacement device includes a fixed bottom plate 1, a moving top plate 2, a piezoelectric actuator 3, a capacitive sensor 4 and an FP cavity 5, and a pressure sensor 4. The bottom of the electric actuator 3 is installed on the fixed bottom plate 1, the moving top plate 2 is installed on the top of the piezoelectric actuator 3, the piezoelectric actuator 3 can drive the moving top plate 2 to translate up and down, and the capacitive sensor 4 is plated on the fixed bottom plate 1 Between the moving top plate 2 and the fixed bottom plate 1 and the moving top plate 2, the FP cavity 5 is embedded to ensure that light can pass through the FP cavity with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com