Rotor structure of synchronous motor

A technology of rotor structure, synchronous motor, applied in the direction of magnetic circuit shape/style/structure, synchronous motor with static armature and rotating magnet, electrical components, etc., can solve the problems of difficult magnets, reduced accuracy, not a solution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 2

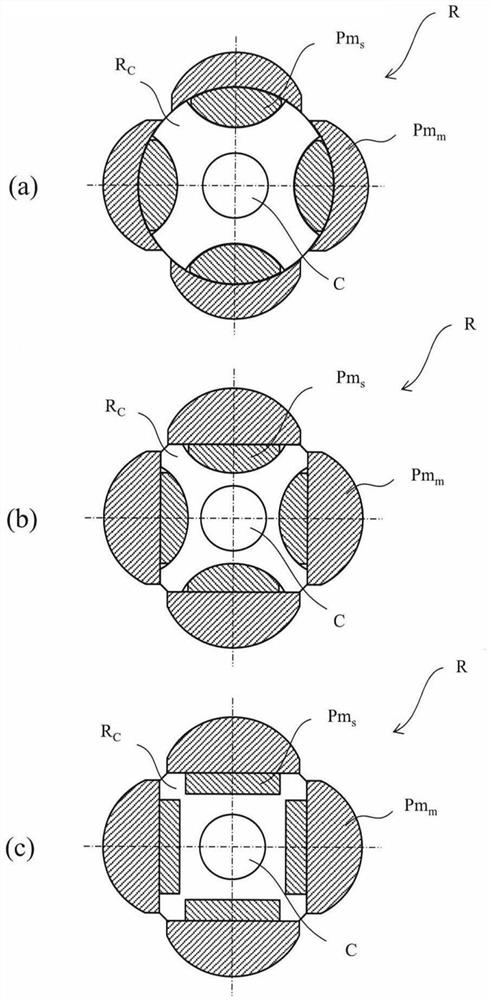

[0062] exist figure 1 In the second embodiment shown in (b), unlike the first embodiment, the rotor core R c is roughly square in shape.

[0063] Rotor core R attached to main shaft C of synchronous motor M c It has a substantially square shape, and each of its four sides constitutes a straight line perpendicular to a line extending from the main axis C in the radial direction. On each of these sides, a total of four main magnets Pm constituting the permanent magnets Pm are joined around the main axis C at each side, that is, every 90 degrees. m . Main magnet Pm m It has a generally known cross-section D shape, and has a rotor core R c The four sides of the inner peripheral side of the contact. Here, as described above, these main magnets Pm m The width is designed to expand to the extreme position.

[0064] in the rotor core R c The main magnet Pm m The inner peripheral surface side, that is, the back side of the m A concave portion, etc., which is convex in the di...

Embodiment approach 5

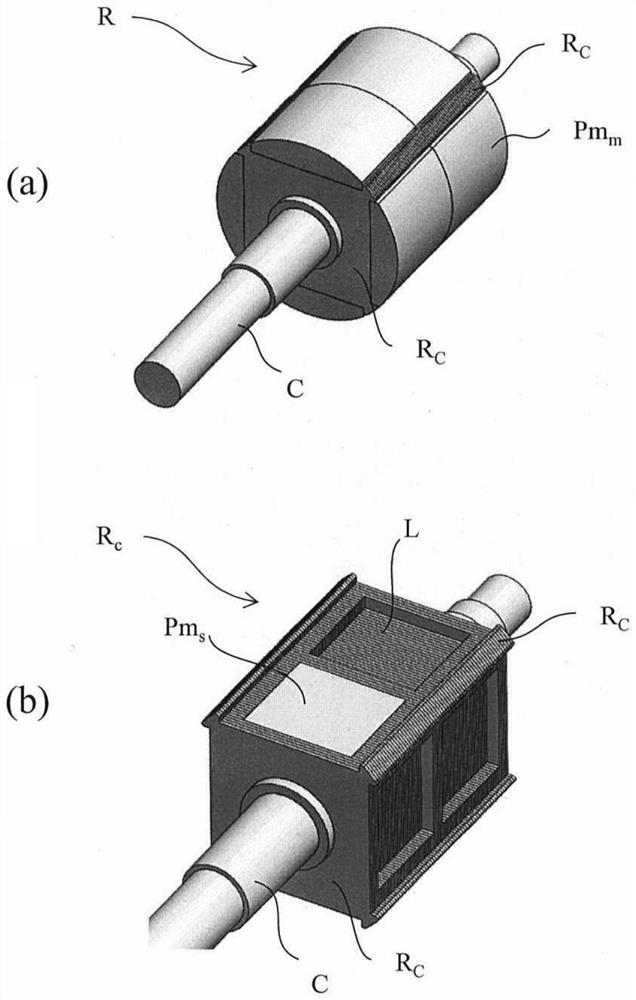

[0079] figure 2 Embodiment 5 shown in (b) with figure 2 Similarly to Embodiment 4 shown in (a), the main magnet Pm of the permanent magnet Pm is m is related to the rotor core R c An example of a concentric ring-shaped magnet.

[0080] In this method, in the rotor core R c The main magnet Pm m The inner peripheral surface side, ie, the back, is provided with independently convex recesses or holes (recesses, etc.). These concave portions and the like include each main magnet Pm m The inner peripheral surface side of which is aligned with the outer peripheral surface side of which the arc is drawn with respect to the main axis, and the inner peripheral surface side that is formed as a straight line perpendicular to the line extending in the radial direction from the main axis C. A total of four auxiliary magnets Pm are embedded and arranged in each concave portion, etc. s . That is, a total of four auxiliary magnets Pm s Around the main axis C every 90 degrees with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com