Experimental system for measuring comprehensive cooling efficiency of turbine blade tip of gas turbine

A gas turbine, cooling efficiency technology, applied in the direction of gas turbine engine testing, measuring devices, engine testing, etc., can solve the problems of lack of experimental system and inability to obtain the internal temperature distribution of blade tip, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

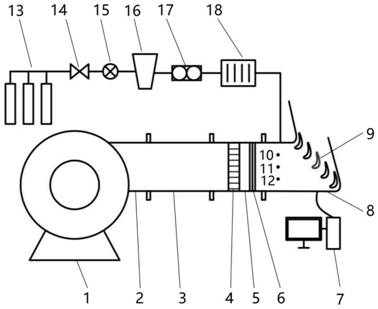

[0036] The invention relates to an experimental system for measuring the comprehensive cooling efficiency of the blade top of a gas turbine, which mainly includes a mainstream system and a cooling gas system.

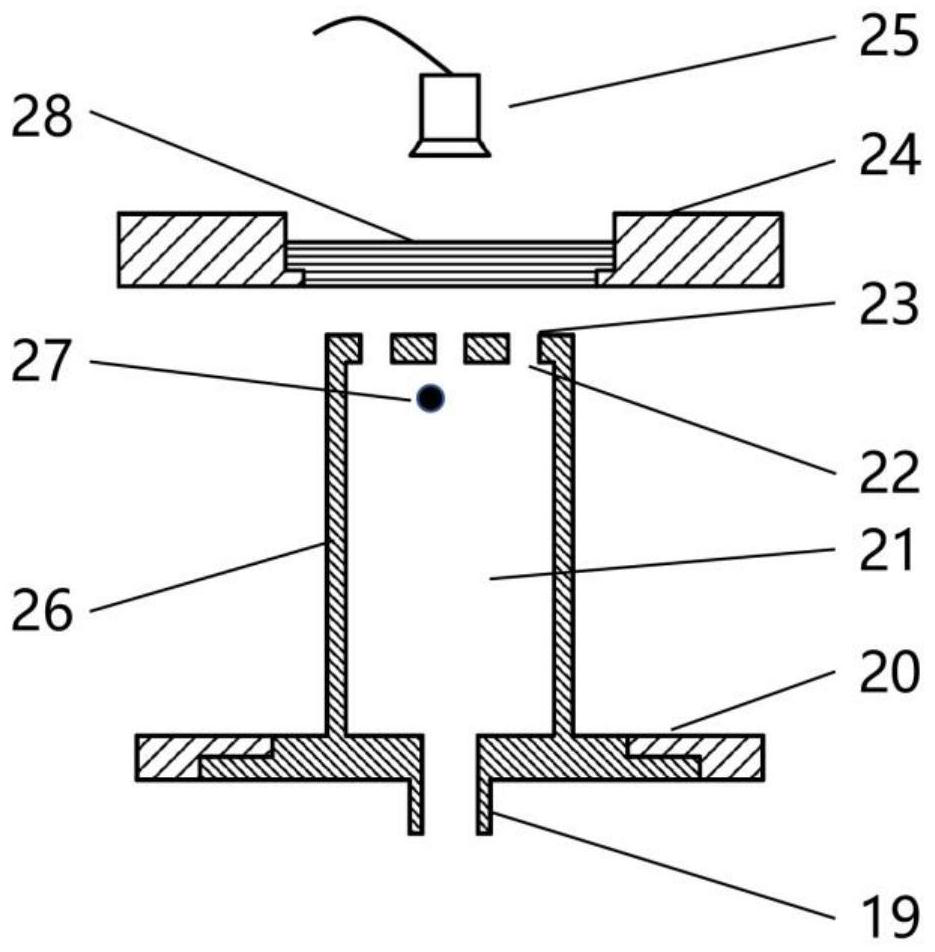

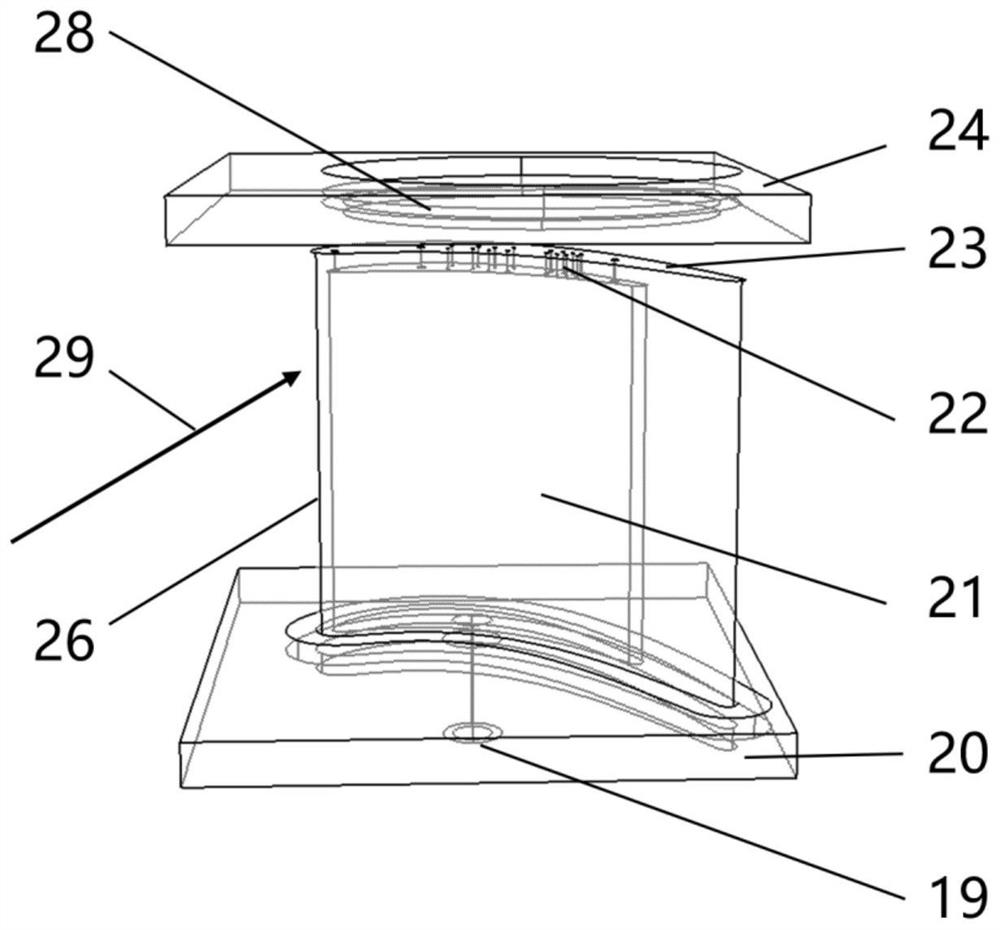

[0037] Such as figure 1 and figure 2 As shown, the mainstream system includes a frequency conversion fan 1, and its fan outlet 2 is connected to a section of pipeline. The end of the pipeline has a corner, and the corner is used as a test section 8. The frequency conversion fan 1 can adjust its speed through a frequency converter, and then pass The fan outlet 2 outputs air with different flow rates to change the mainstream working condition entering the test section 8 . The blade 26 to be measured is set in the test section 8, and the air outlet of the variable frequency fan 1 is facing the leading edge of the blade 26 to be measured, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap