Medicinal material decocting and separating device and medicinal material decocting and separating method

A separation device and decoction technology, which is applied in the direction of making medicines into special physical or taking form devices, gravity filters, etc. fully cooked effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

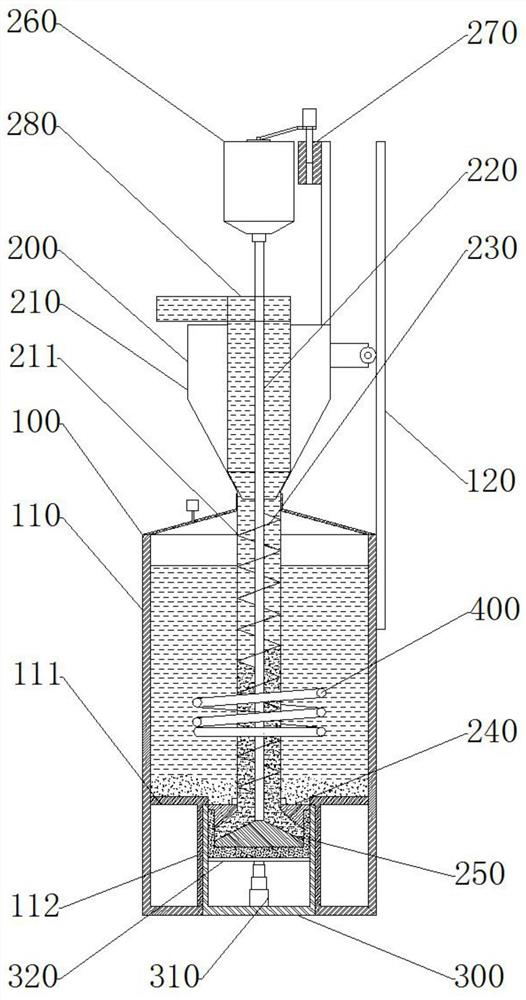

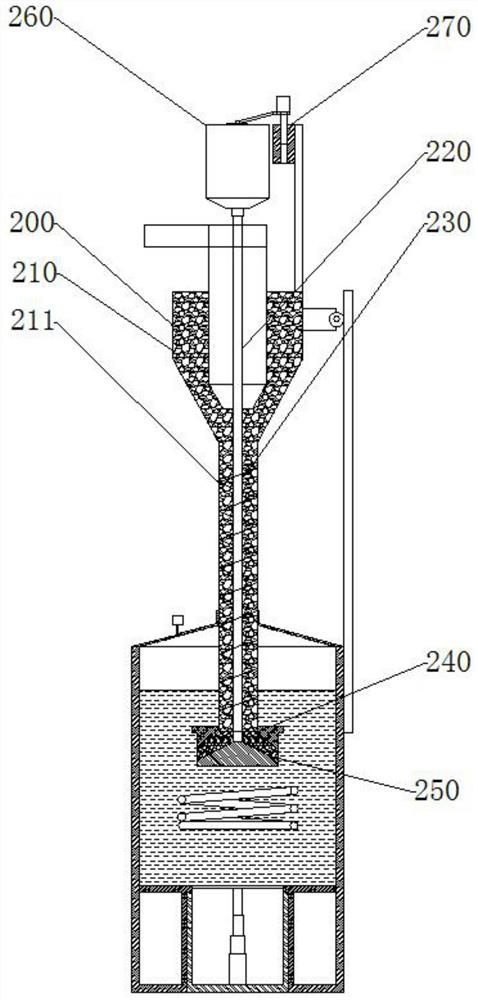

[0049] like Figure 1-4 As shown, a device for decocting and separating medicinal materials includes a decoction assembly 100 for decocting medicinal materials. The decoction assembly 100 includes a tank body 110 and a moving part 120; it also includes an advancing assembly 200 and a heating part 400;

[0050] The tank body 110 is used to accommodate water and medicinal materials to form a decoction space;

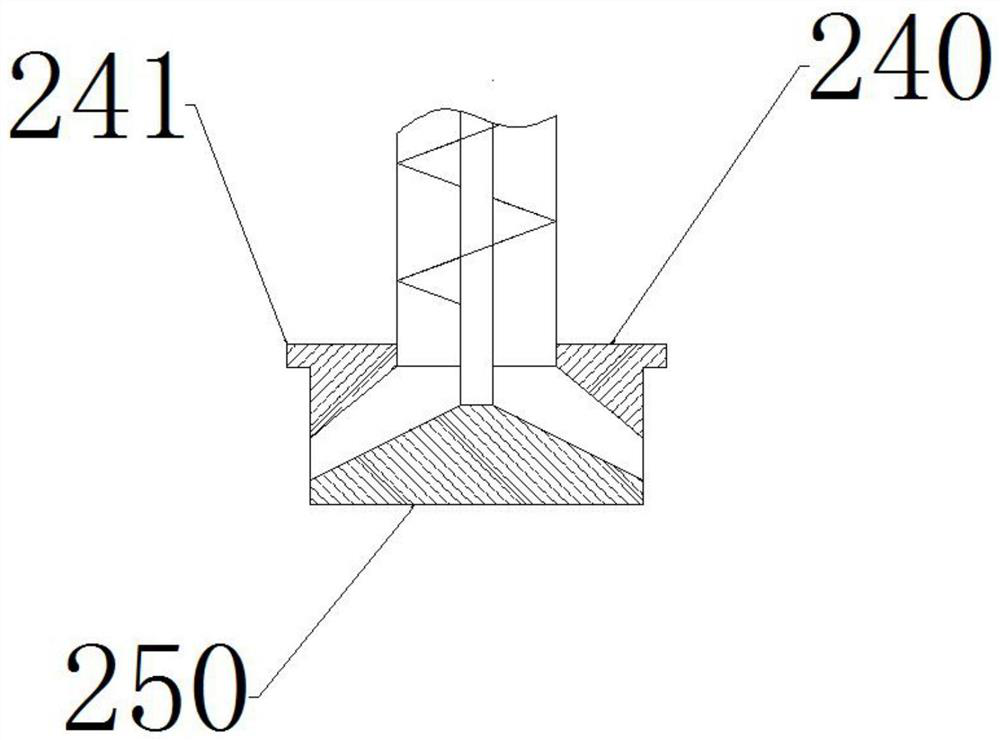

[0051] The advance assembly 200 is used to feed and extract medicinal liquid into the tank body 110; Grinding head 250, motor 260, liquid taking tube 280;

[0052] The feed tank 210 is used to hold the medicinal materials with an open mouth (the feed tank 210 is bucket-shaped); the bottom end of the feed tank 210 is connected to the feeding pipe 211; the feeding pipe 211 extends into the tank from the top opening of the tank body 110 Inside the body 110; the spiral deflector 230 is fixed on the rotating shaft 220, the rotating shaft 220 is coaxial with the feeding tube 2...

Embodiment 2

[0059] In addition to separation, it would be more convenient if the medicinal residues can be easily discharged during separation. Therefore described tank body 110 increases inner bottom 111 and slag outlet part 112; Described inner bottom 111 is the annular outer ring and tank body 110 inner wall sealed and fixed; The top of part 112 is sealed and fixed with the inner ring of the inner bottom;

[0060] It also includes a slag discharge tank 300, which is detachably and sealingly connected to the top of the slag discharge part 112;

[0061] The outer surface of the upper grinding head 240 and the lower grinding head 250 is a coaxial cylindrical surface, and the diameter of the cylindrical surface is the same as the inner diameter of the slag discharge pipe 300, and the diameter of the outer surface of the upper grinding head 240 and the lower grinding head 250 is the same as that of the discharge pipe. The gap between the slag tanks 300 is not more than 0.3 mm; the slag dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com