Automatic vacuum scouring device

A vacuum and scouring technology, applied in silk fiber production, textile and papermaking, mechanical processing, etc., can solve the problems of unstable quality of silkworm cocoon processing products, failure to save resources and time, and uneven scouring of silkworm cocoons. Achieve the effect of overcoming insufficient water absorption, uniform cooking and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

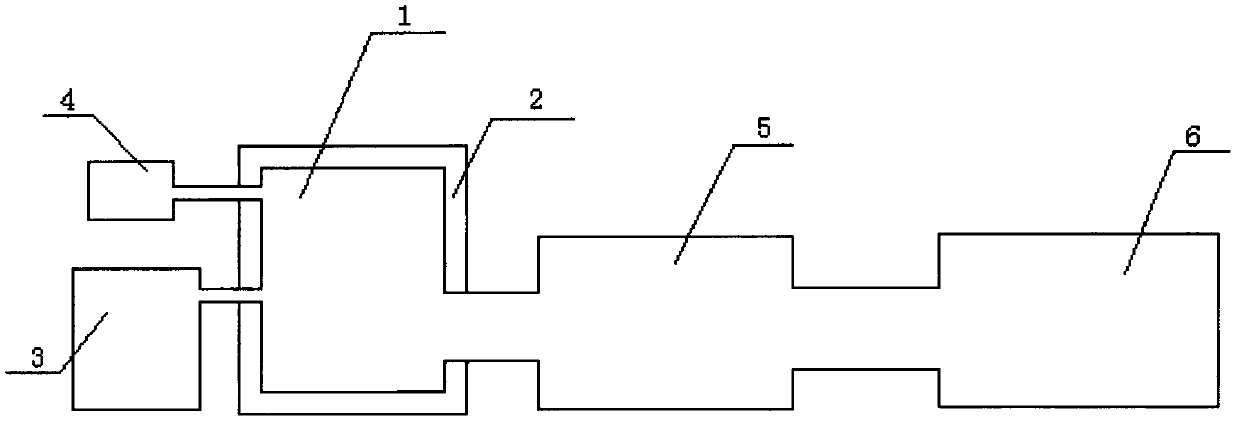

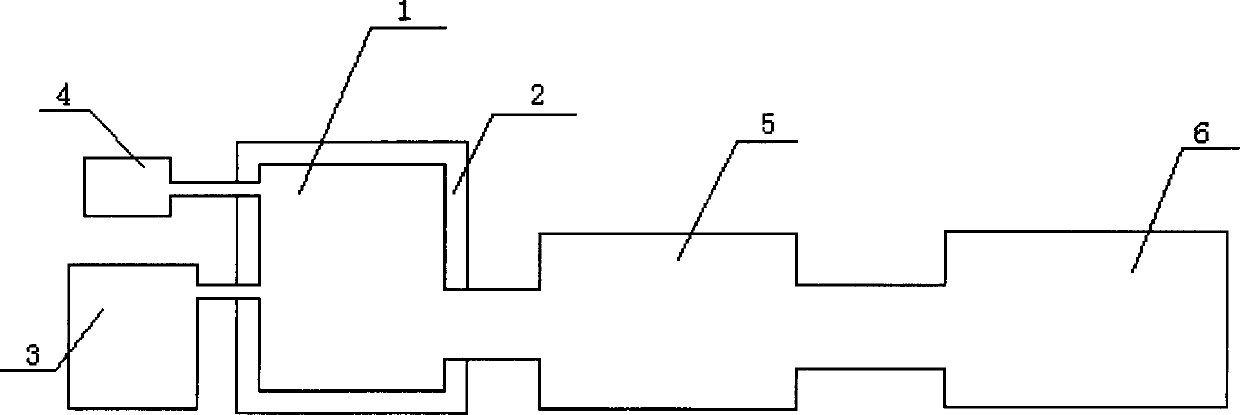

[0008] An automatic vacuum smelting device as shown in the drawings, the device includes a vacuum barrel 1, an insulation layer 2, a water storage tank 3, a vacuum pump 4, a pupa removal machine 5, a biochemical cylinder 6, and the vacuum barrel 1 The outer layer is provided with a thermal insulation layer 2. One end of the vacuum barrel 1 is connected with a vacuum pump 4 and a water storage tank 3, and the other end of the vacuum barrel 1 is connected with a pupation machine 5 and a biochemical cylinder 6 in sequence. The vacuum pump 4 and the water storage tank All 3 are connected and fixed to the vacuum barrel 1 through pipelines.

[0009] The smelting process of the automatic vacuum smelting device is as follows: place the cocoons in a self-developed vacuum barrel 1 and vacuum through the vacuum pump 4. The vacuum barrel 1 has two layers, and the outer layer of the vacuum barrel 1 is the heat insulation layer 2. When the preset value is reached, continue to maintain the vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com