Rotary sealing device controlled by wave spring

A wave spring and rotary seal technology, applied in the hydraulic field, can solve the problems of reliability, durability, storage limitations of parts, inability to adjust the medium pressure in the transportation channel, etc., and achieve light weight, simple structure, saving effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] This part is the embodiment of the present invention, which is used to explain and illustrate the technical solution of the present invention.

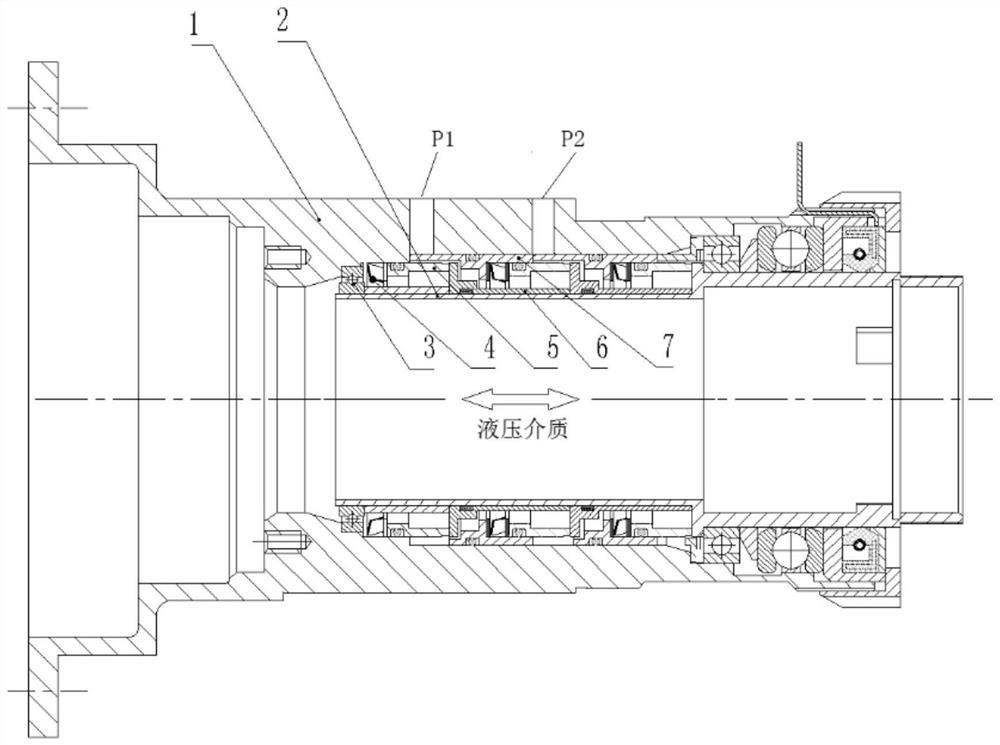

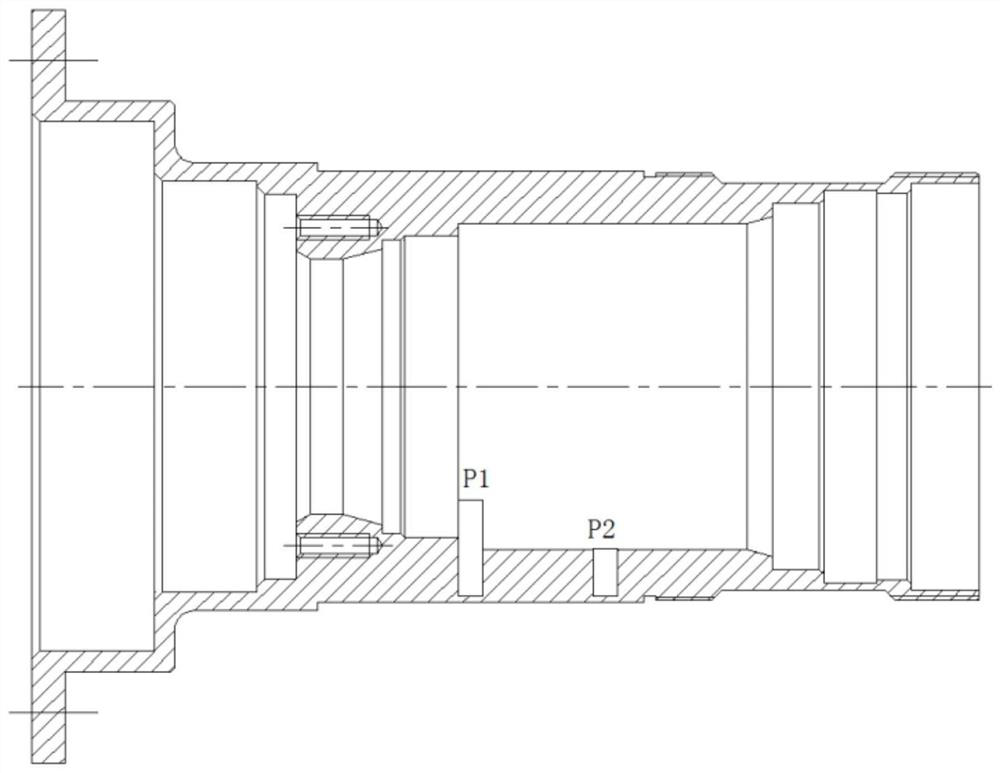

[0036] A rotary sealing device controlled by a wave spring, including a housing 1 and an internal channel 2, the internal channel 2 is set in the housing 1 through a bearing 3 and can rotate relative to the housing 1; there is a cavity for transporting medium in the middle of the internal channel 2 , the cavity communicates with the bearing 3; there is also an elastic combined sealing structure between the inner channel 2 and the housing 1, the elastic combined sealing structure is arranged behind the bearing 3, and the medium in the cavity passes through the bearing 3 and then is sealed by the elastic combined sealing structure Keep sealed.

[0037] There is also a leakage port on the side of the housing 1, and the leakage port of the housing 1 is located at the position corresponding to the combined sealing structure. The com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com