Suspension type transportation device

A transportation device and suspension technology, which is applied in the field of suspension transportation devices, can solve problems such as difficult to meet precise splicing, weakening of track and cantilever beam section, unfavorable construction safety, etc., to reduce splicing difficulty, precise splicing, and improve safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

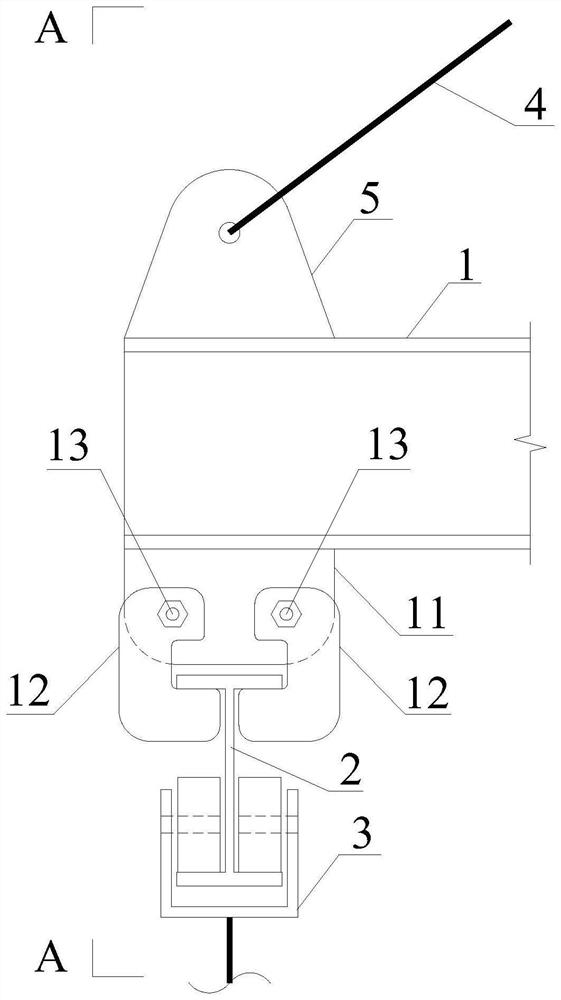

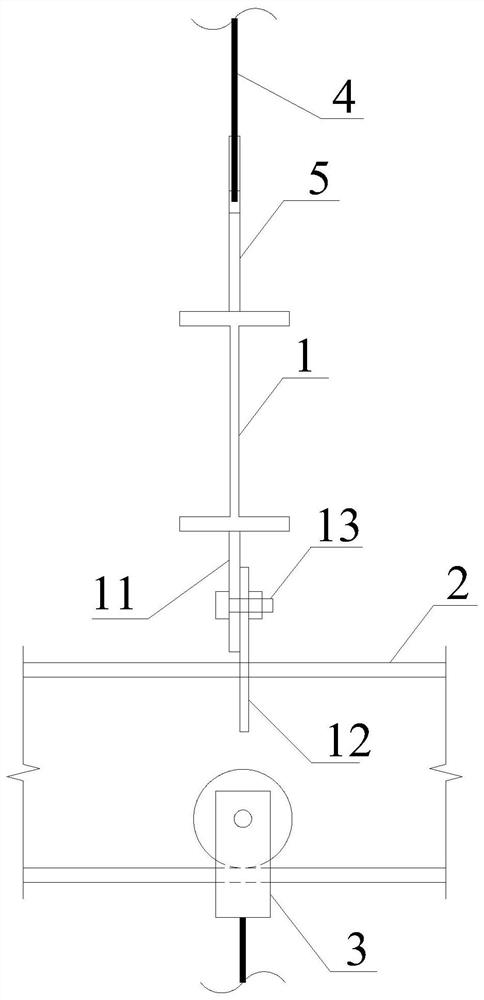

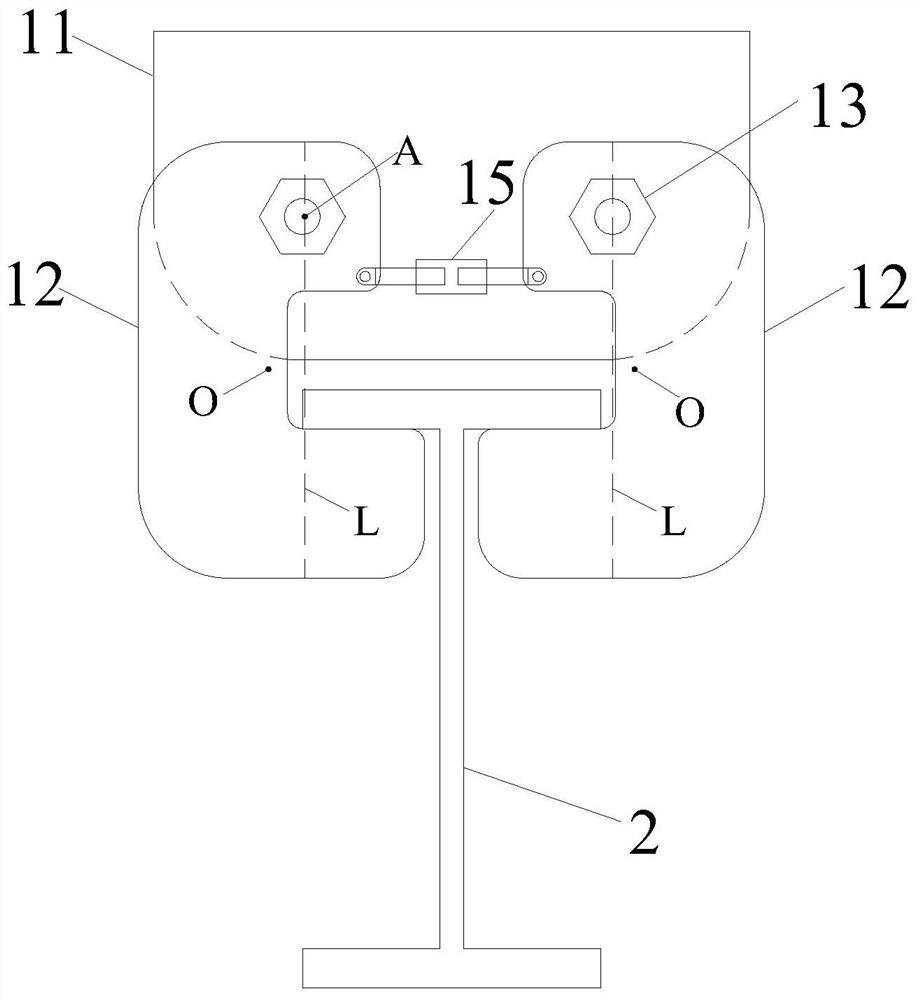

[0038] combine figure 1 and figure 2 As shown, a suspended transportation device provided in this embodiment includes a cantilever beam, a horizontal track and a walking trolley. One end of the cantilever beam is fixed on the building structure, and the other end can be provided with an ear plate on the top and can be connected by a pull rod or a pull bar. The cable is suspended on the building structure above, and the cantilever beam can be H-shaped steel, I-shaped steel, channel steel, rectangular steel pipe or other structural forms. The horizontal track is set under the cantilevered end of the cantilever beam. The horizontal track is I-shaped steel or H-shaped steel. The trolley is suspended on the horizontal track and can walk along the horizontal track. The rollers of the trolley can be supported on the lower flange of the horizontal track. In general, the walking trolley can realize the walking control by driving the motor, and the specific implementation form can ado...

Embodiment 2

[0047] This embodiment provides a method for installing the suspended transport device. For the specific structure of the suspended transport device, refer to the first embodiment. Described installation method comprises the steps:

[0048] Step 1. A connecting plate is pre-set under the cantilevered end of the cantilever beam, and a pair of buckle plates are arranged on the connecting plate, and the buckle plate and the connecting plate are hingedly arranged; the end of the cantilever beam without a connecting plate is fixed to the building structure Above, the top of the cantilevered end is suspended on the building structure above through a tie rod or a stay cable.

[0049] Step 2. Open and fix the L-shaped buckle end of the buckle plate.

[0050] Step 3. Lift the horizontal guide rail so that the horizontal rail is laid along the direction perpendicular to the cantilever beam, so that the upper flange of the horizontal rail is located directly below the connecting plate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com