Polyurethane rigid foam combined polyether, polyurethane rigid foam, and preparation method

A technology of rigid polyurethane foam and combining polyether, which is applied in the field of polyurethane materials, can solve the problems of poor dimensional stability of polyurethane rigid foam, poor foam fluidity, and high processing difficulty, achieve good foam dimensional stability, reduce the viscosity of material liquid, and have good performance. The effect of facilitating transportation and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

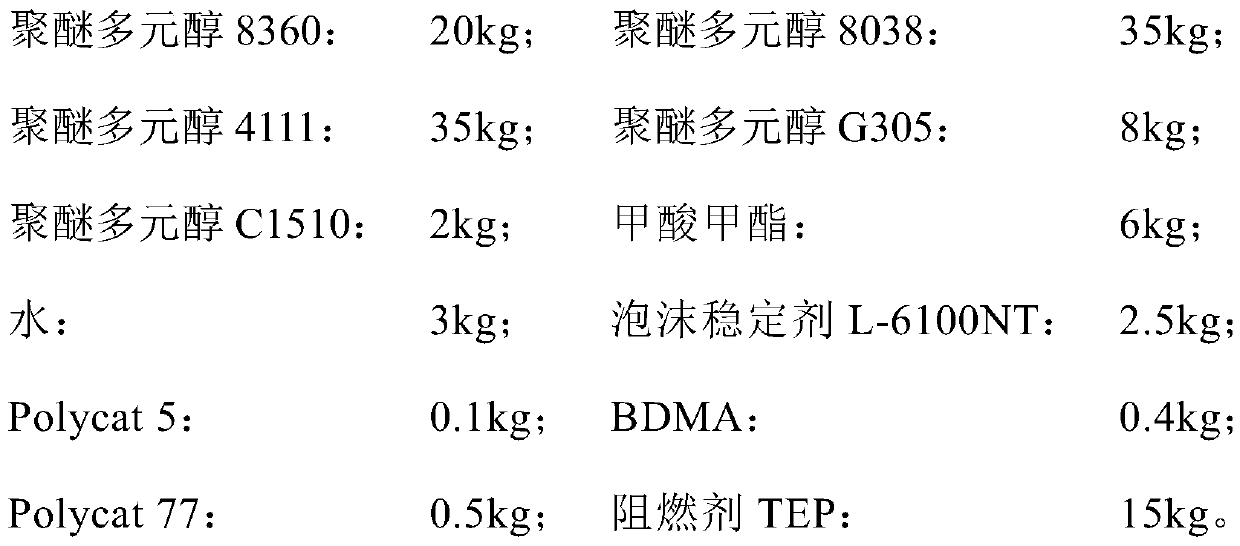

[0066] A polyurethane rigid foam combined polyether, the raw materials are as follows:

[0067]

[0068] The preparation method of above-mentioned polyurethane rigid foam combination polyether is as follows:

[0069] (1) each raw material is weighed, and other raw materials that remove methyl formate are put into the mixing kettle, and stirred for 30min at 2000r / min to obtain mixture;

[0070] (2) Turn on the cooling water of the mixing kettle, cool the mixture to below 15°C, add methyl formate, stir at 1500r / min for 30min, discharge and pack.

[0071] A rigid polyurethane foam, the preparation method is as follows:

[0072] (1) take by weighing the polyurethane rigid foam combination polyether (white material) 127.5kg and isocyanate PM-200 (black material) 150kg of above-mentioned preparation respectively;

[0073] (2) Add the black material and the white material into the high-pressure machine respectively, set the mixing ratio of black and white material in the high-pr...

Embodiment 2

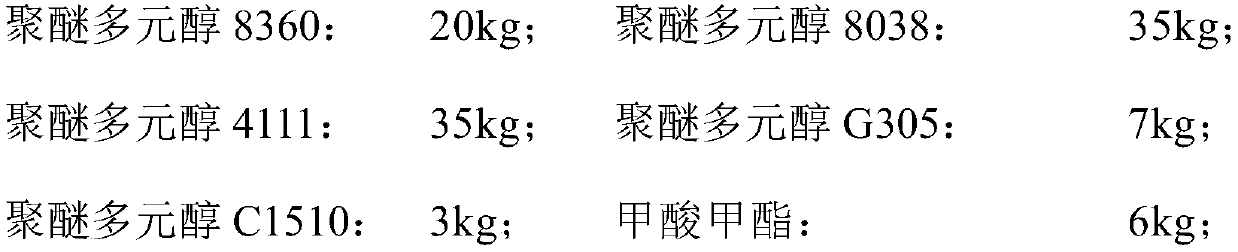

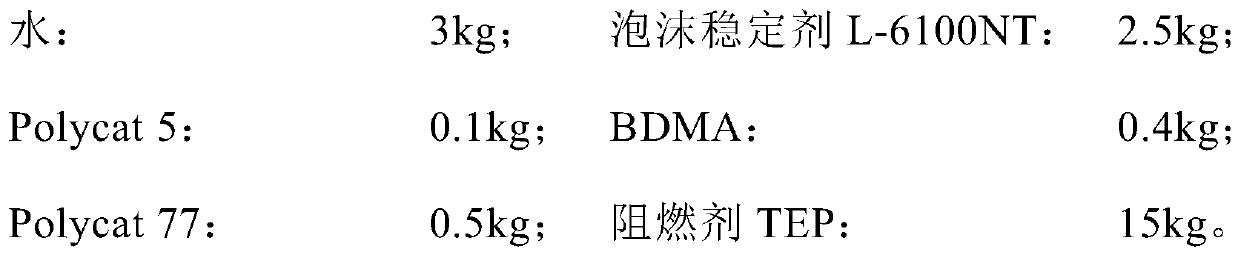

[0075] A polyurethane rigid foam combined polyether, the raw materials are as follows:

[0076]

[0077]

[0078] The preparation method of above-mentioned polyurethane rigid foam combination polyether is as follows:

[0079] (1) each raw material is weighed, and other raw materials that remove methyl formate are put into the mixing kettle, and stirred for 30min at 2000r / min to obtain mixture;

[0080] (2) Turn on the cooling water of the mixing kettle, cool the mixture to below 15°C, add methyl formate, stir at 1500r / min for 30min, discharge and pack.

[0081] A rigid polyurethane foam, the preparation method is as follows:

[0082] (1) take by weighing the polyurethane rigid foam combination polyether (white material) 127.5kg and isocyanate PM-200 (black material) 150kg of above-mentioned preparation respectively;

[0083] (2) Add the black material and the white material into the high-pressure machine respectively, the mixing ratio of black and white material in the...

Embodiment 3

[0085] A polyurethane rigid foam combined polyether, the raw materials are as follows:

[0086]

[0087] The preparation method of above-mentioned polyurethane rigid foam combination polyether is as follows:

[0088] (1) each raw material is weighed, and other raw materials that remove methyl formate are put into the mixing kettle, and stirred for 30min at 2000r / min to obtain mixture;

[0089] (2) Turn on the cooling water of the mixing kettle, cool the mixture to below 15°C, add methyl formate, stir at 1500r / min for 30min, discharge and pack.

[0090] A rigid polyurethane foam, the preparation method is as follows:

[0091] (1) take by weighing the polyurethane rigid foam combination polyether (white material) 127.5kg and isocyanate PM-200 (black material) 150kg of above-mentioned preparation respectively;

[0092](2) Add the black material and the white material into the high-pressure machine respectively, the mixing ratio of black and white material in the high-pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com