Alkali washing device for artificial diamond production

A technology of artificial diamond and alkaline cleaning device, which is applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., and can solve the problems of difficult cleaning, filtration, and inability to meet the requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

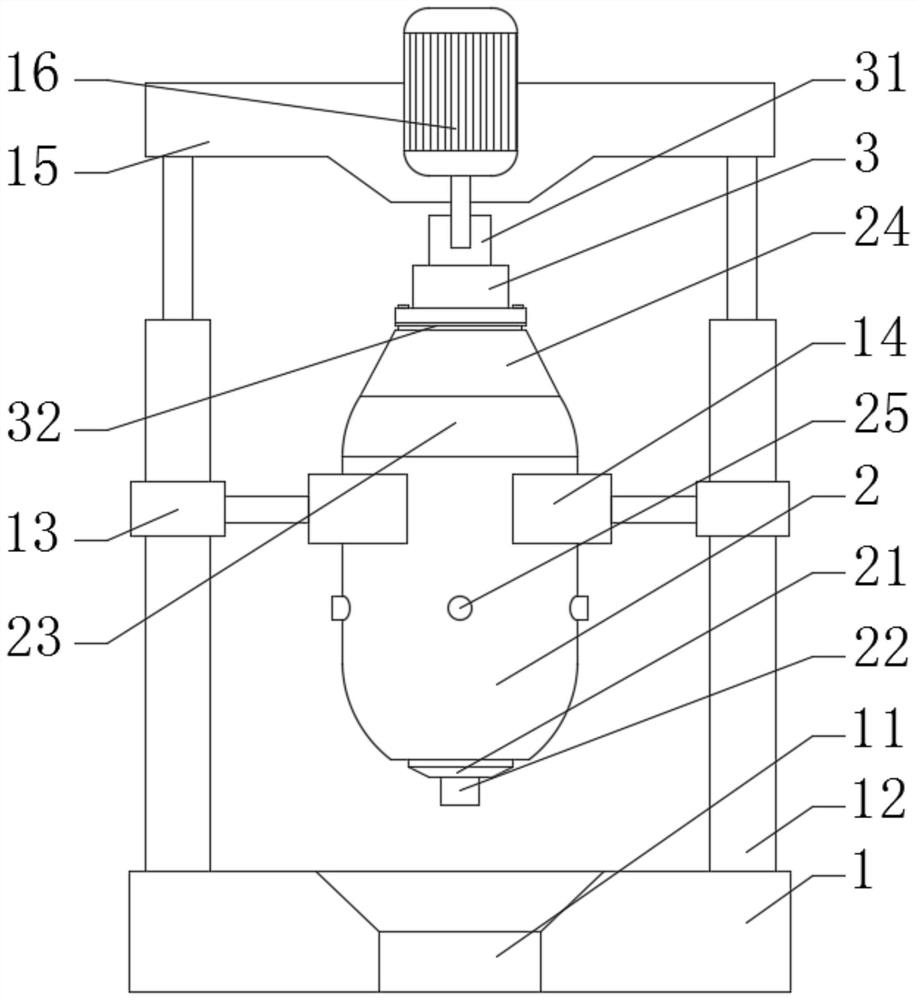

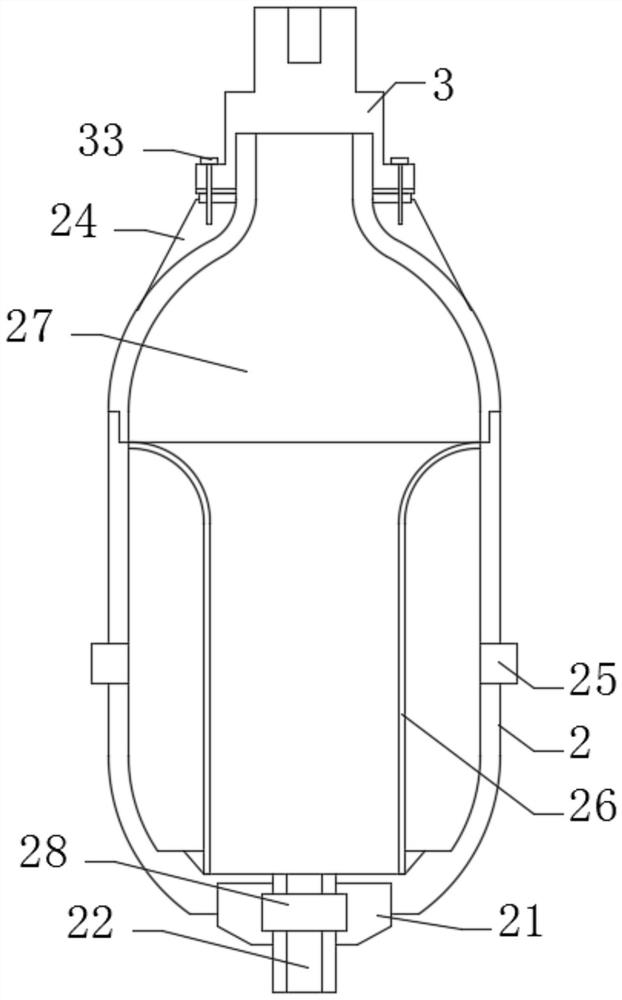

[0024] Please refer to figure 1 and figure 2 ,in, figure 1 It is a schematic diagram of the overall front view part of the sectional structure of the present invention; figure 2 It is a schematic cross-sectional structure schematic diagram of the alkali cleaning tank of the present invention; a kind of artificial diamond production alkali cleaning device specifically described includes: a chassis 1, and the two sides of the upper surface of the chassis 1 are welded with telescopic rods 12, A top frame 15 is installed at the top of the telescopic rod 12 through bolts, and a motor 16 is installed at the middle of the top frame 15 through bolts.

[0025] The seal 3, the power output end of the motor 16 penetrates through the lower surface of the top frame 15 and is welded with a top frame 31, and the lower surface of the top frame 31 is welded with a seal 3.

[0026] Wherein, when in use, the motor 16 is combined with the top frame 31 to realize the rotation effect for the a...

Embodiment 2

[0035] Please refer to figure 1 and figure 2 ,in, figure 1 It is a schematic diagram of the overall front view part of the sectional structure of the present invention; figure 2 It is a schematic cross-sectional structure schematic diagram of the alkali cleaning tank of the present invention; a kind of artificial diamond production alkali cleaning device specifically described includes: a chassis 1, and the two sides of the upper surface of the chassis 1 are welded with telescopic rods 12, A top frame 15 is installed at the top of the telescopic rod 12 through bolts, and a motor 16 is installed at the middle of the top frame 15 through bolts.

[0036] The seal 3, the power output end of the motor 16 penetrates through the lower surface of the top frame 15 and is welded with a top frame 31, and the lower surface of the top frame 31 is welded with a seal 3.

[0037] Wherein, when in use, the motor 16 is combined with the top frame 31 to realize the rotation effect for the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com