Device for separating rice embryos in batches

A rice embryo, batch technology, applied in centrifuges, food science, metal processing and other directions, can solve the problems of low work efficiency and unsuitable for factory mass production, and achieve the effect of improving cutting efficiency and improving food taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

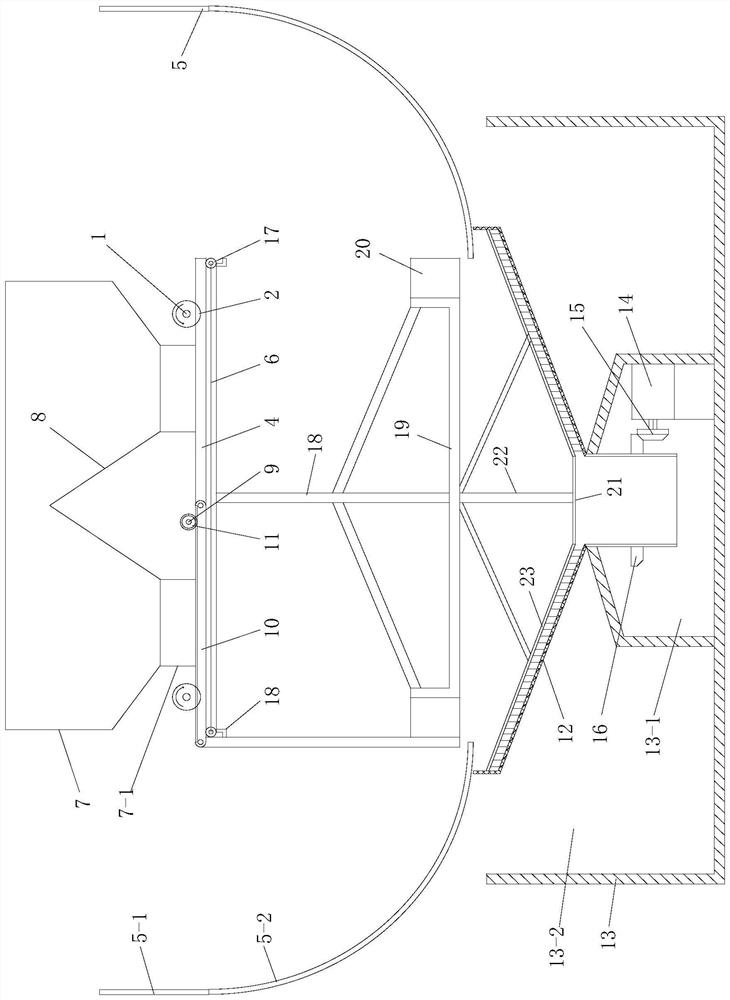

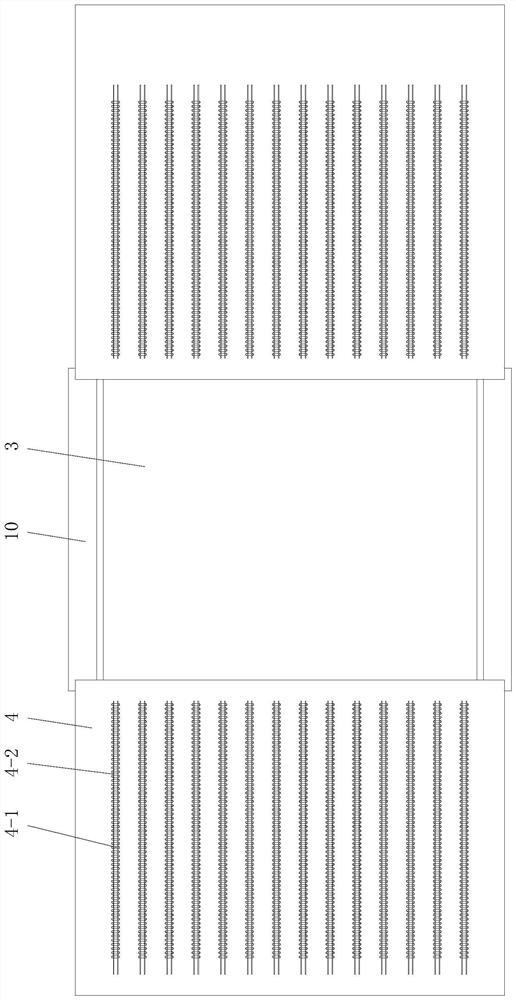

[0018] Specific implementation mode one: combine figure 1 and figure 2 Illustrate this embodiment, a device for separating rice embryos in batches described in this embodiment, which includes two cutting units, each of which includes a cutter shaft 1 and multiple groups of cutters 2; multiple groups of cutters 2 are set side by side On the cutter shaft 1, one end of the cutter shaft 1 is connected with the motor shaft of the drive motor, and each group of cutters 2 is composed of two cutters 2; Mechanism, two rice plates 4, two baffle plates 5 and supporting plates 6;

[0019] Supporting plate 6 is arranged horizontally, and two rice plates 4 are horizontally arranged on the upper surface of supporting plate 6 in a font, and connecting plate 3 is horizontally arranged between two rice plates 4, and the two ends of connecting plate 3 are connected with two respectively. Two rice plates 4 are rotationally connected, and two baffle plates 5 are symmetrically arranged at the tw...

specific Embodiment approach 2

[0020] Specific implementation mode two: combination figure 1 and figure 2 Illustrate this embodiment, the described rice filling mechanism of the device of a kind of batch separation rice embryo described in this embodiment comprises rice filling bin 7 and decimeter bump 8; Protrusion 8 is arranged on the middle part in the rice storage bin 7, and the bottom of the rice storage bin 7 is provided with two outlets 7-1, and each outlet 7-1 is respectively positioned on the upper surface of a rice plate 4, and the outlet 7-1 The bottom edge is not adjacent to the upper surface of the rice board 4 . Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0021] Specific implementation mode three: combination figure 1 and figure 2 Illustrate this embodiment, the rice plate drive mechanism of a device for separating rice embryos in batches described in this embodiment includes a gear shaft 9, two racks 10 and two gears 11; two racks 10 are arranged side by side in parallel On the upper surface of the supporting plate 6, and two racks 10 are positioned between the two rice plates 4, the two ends of the rack 10 are respectively rotatably connected with the two rice plates 4, and the gear shaft 9 is arranged on the sides of the two racks 10. Above, one end of the gear shaft 9 is fixedly connected with the rotating shaft of the drive motor, and two gears 11 are fixedly sleeved on the gear shaft 9, and each gear 11 meshes with a corresponding rack 10 respectively. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com