A device for aligning rice grains and a brown rice processing machine using the device and keeping the whole rice germ

A rice germ and processing machine technology, which is applied in application, metal processing, grain germ removal, etc., can solve the problems of low germ retention rate and integrity rate, bad taste, etc., reduce the time of oxidation and photolysis, and benefit health effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0021] Specific implementation mode one: combine Figure 5 and Image 6 Describe this embodiment, the rice grain alignment device of this embodiment comprises high-frequency vibrating device 30, rice falling board 31, left baffle 32, right baffle 33 and a plurality of arc-shaped projections 34, the elongated rice falling board The left and right baffles 32 and right baffles 33 are respectively fixed on the left and right sides of the upper surface of the 31, the high-frequency vibration device 30 is fixed on the lower surface of the rice falling board 31, and a plurality of arc-shaped protrusions 34 are arranged along the upper surface of the rice falling board 31. The longitudinal direction is evenly arranged and forms a wave shape in the longitudinal direction of the rice falling board 31, and the vibration formed by the high-frequency vibration device 30 is to vibrate along the left and right directions of the rice falling board 31, as Figure 8 Vibration direction shown i...

specific Embodiment approach 2

[0022] Specific implementation mode two: combination Figure 7 and Figure 8 Describe this embodiment, the difference between this embodiment and Embodiment 1 is that it also includes a plurality of rotating rollers 35 and a power transmission device 37, the top of the arc-shaped protrusion 34 has a gap 36, and the rotating roller 35 is on the arc-shaped protrusion. From the bottom of 34 and the wheel rim protrudes from the elongated gap 36, and the output end of the power transmission device 37 is connected with the rotating roller 35. The rotating roller 35 rotates at a low speed through the power transmission device 37, so that the rice grains slide down more smoothly under the rolling friction of the rotating roller 35. The power transmission device 37 can use a gear belt or a flat belt transmission mode to input rotational power at the shaft end of each rotating roller 35 . Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

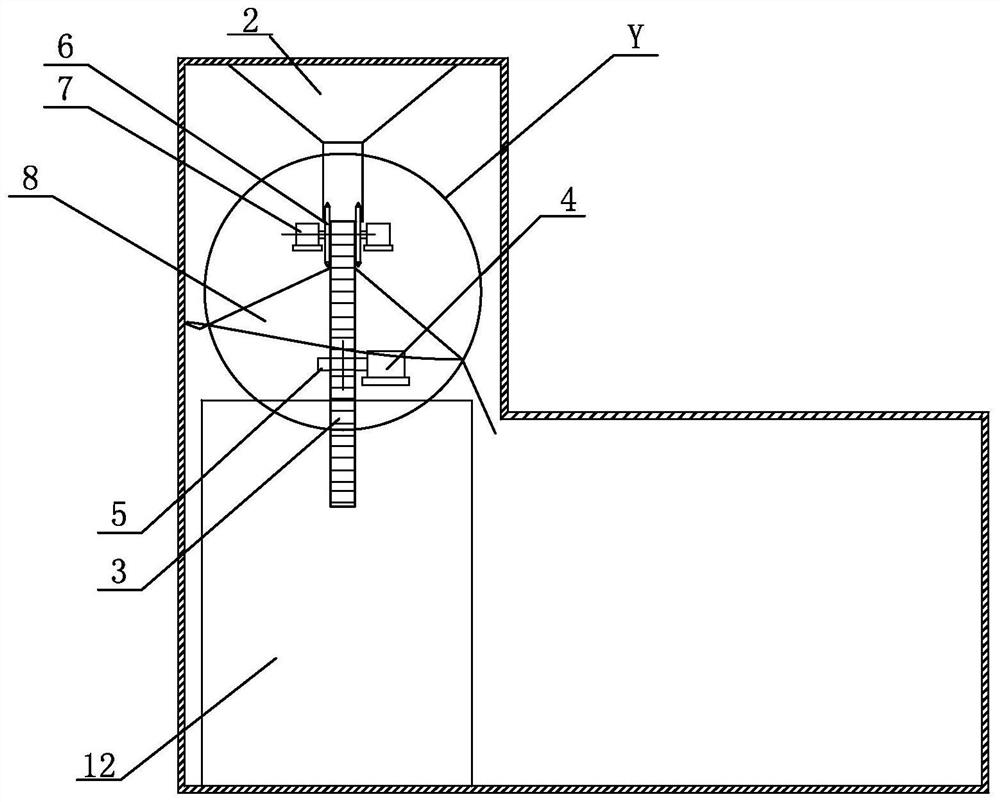

[0023] Specific implementation mode three: combination Figure 1 to Figure 6 Describe this embodiment, a kind of processing device of this embodiment retains the whole rice germ to comprise shell 1 and hopper 2, it also comprises rice grinder 12, rice grain aligning device X and brown rice grain cutting two-end system Y, hopper 2 is set The top inside the housing 1 and its inlet communicate with the outside, the lower outlet of the hopper 2 is connected to the inlet of the rice grain alignment device X, the rice grain alignment device X is arranged obliquely and its outlet extends to the system Y at both ends of the brown rice grain cutter; The two-end system Y is installed in the middle of the shell 1; the rice grinder 12 is arranged under the brown rice grain cutting two-end system Y in the shell 1;

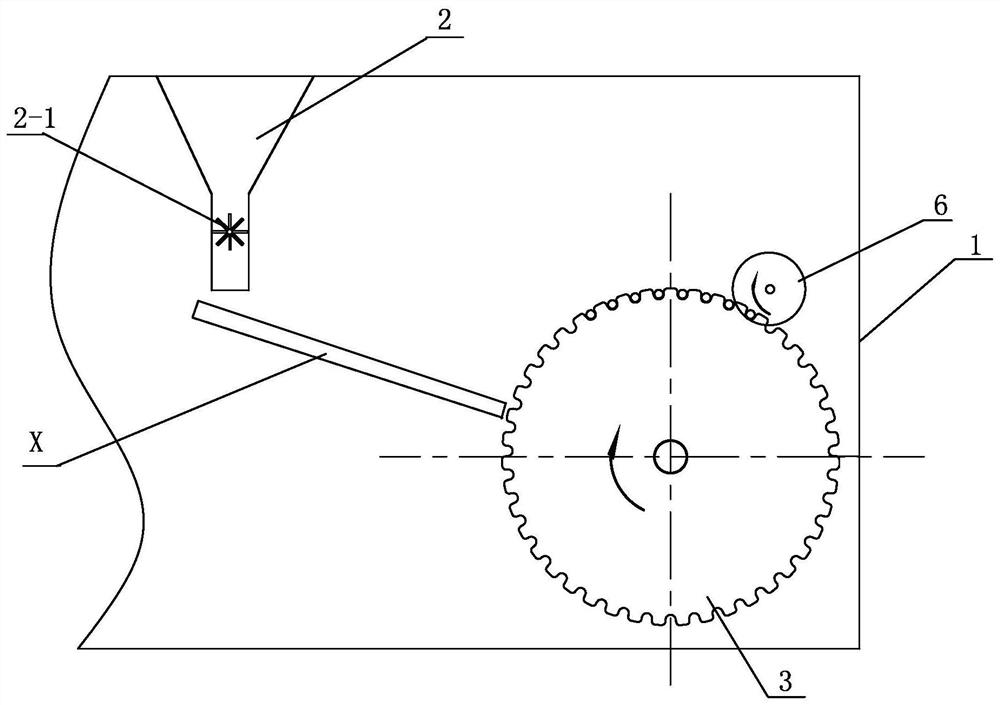

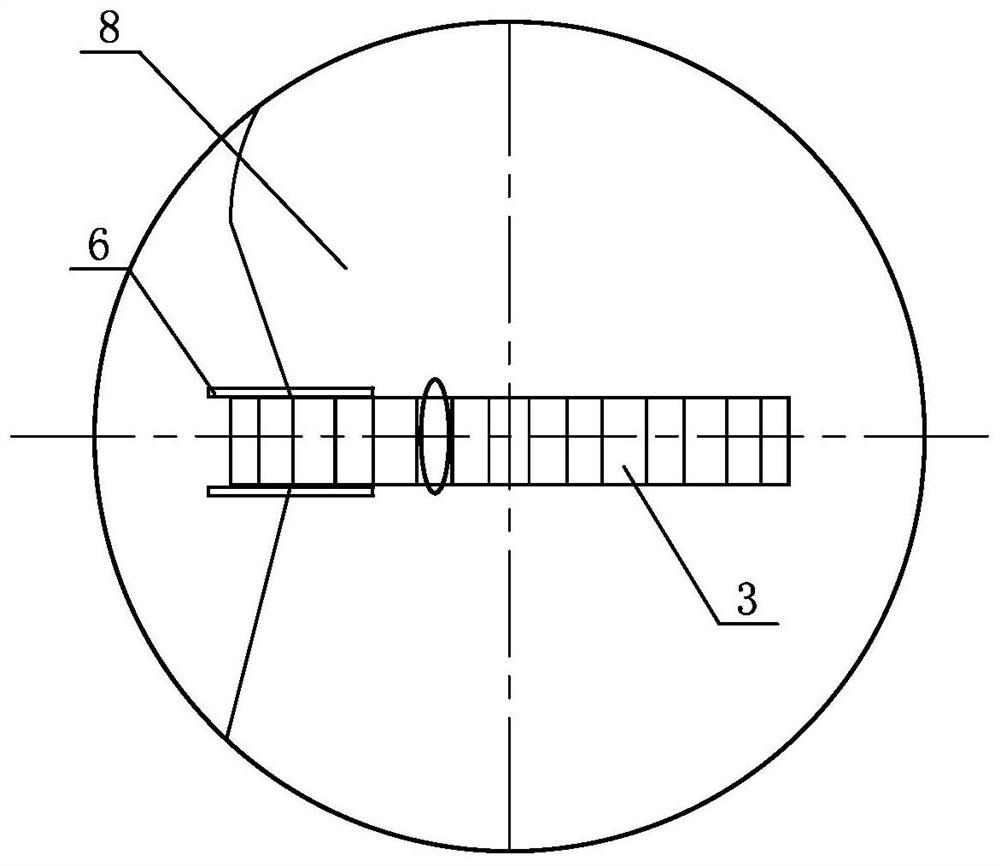

[0024] The brown rice grain cutting system Y includes a sheave 3, a first motor 4, a sheave shaft 5, a rice point collection baffle 8, two cutters 6 and two second motors 7, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com