Rice grain cutting device and processing machine for keeping whole rice germ using it

A rice grain cutting technology, applied in the field of processing machines that leave the whole rice germ, can solve the problem of losing germ

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

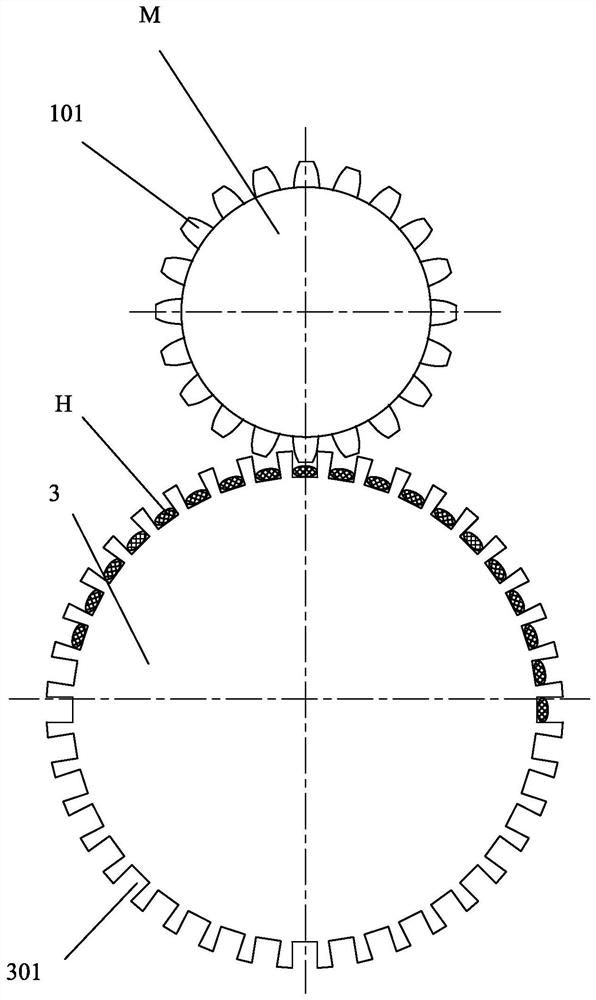

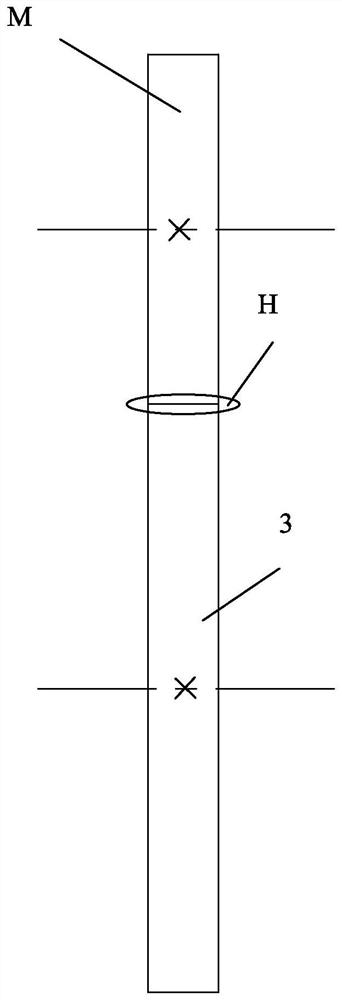

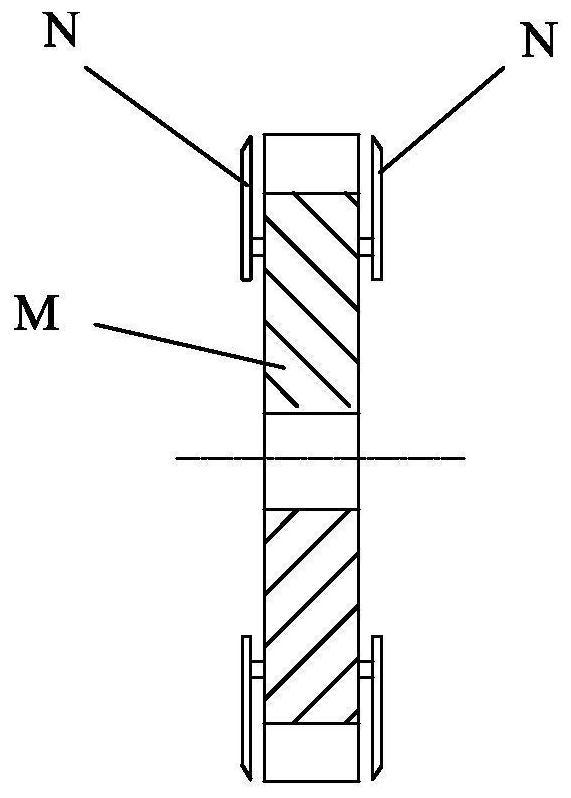

[0011] Specific implementation mode 1: This implementation mode will be specifically described below in conjunction with the accompanying drawings of the description. The rice grain cutting device of the present embodiment comprises a sheave 3, a rice pressing wheel M and a plurality of rice cutting knives N, and a plurality of rice grooves 301 are evenly opened on the outer cylindrical surface of the sheave 3, and the rice pressing wheel M A plurality of gear teeth 101 are evenly distributed on the outer cylindrical surface of the groove wheel 3 and the rice pressing wheel M is arranged adjacent to the side and the gear teeth 101 are sequentially meshed with the rice groove 301. The left side and the right side of each gear tooth 101 A rice cutter N is arranged on each side, the cutting edge of the rice cutter N points out of the circumference of the rice pressing wheel M and is flush with the top of the gear teeth 101, and the axial gap O between the two rice cutters N is gre...

specific Embodiment approach 2

[0018] Specific implementation mode two: the following combination Figure 9 This embodiment will be specifically described. The difference between this embodiment and Embodiment 1 is that the elastic contraction structure includes a pressure head 102, a plunger 105 and a spring 103, and a plunger hole 104 is opened at the top of the gear teeth 101, and the plunger 105 is arranged on the plunger A spring 103 is provided between the bottom of the plunger hole 104 and the plunger 105 , and the top of the plunger 105 is fixed to the pressure head 102 . With such arrangement, the elastic pressure is sufficient, and the reliability of the meshing transmission can also be ensured. Others are the same as the first embodiment.

specific Embodiment approach 3

[0019] Specific implementation mode three: the following combination Figure 5 to Figure 6 This embodiment will be specifically described. The difference between this embodiment and Embodiment 1 is that the bottom of the meter groove 301 of the sheave 3 is low in the middle and high at both ends in the circumferential direction, and the bottom of the meter groove 301 is low in the middle and high at both ends in the axial direction. Such a setting adapts to the shape of the rice grains, making it easier for the rice grains H to be positioned in the rice tank 301, and more stable during the guillotine cutting, so as to avoid the cracking and shattering of the rice grains during the guillotine cutting process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com