Upper and lower double-layer steel bridge beam falling structure for highway bridge and railway bridge and beam falling method of upper and lower double-layer steel bridge beam falling structure

A technology for railway bridges and highway bridges, which is applied in bridges, bridge parts, bridge construction, etc., and can solve problems such as difficult transportation of steel structure modules, large traffic volume, and limited construction sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

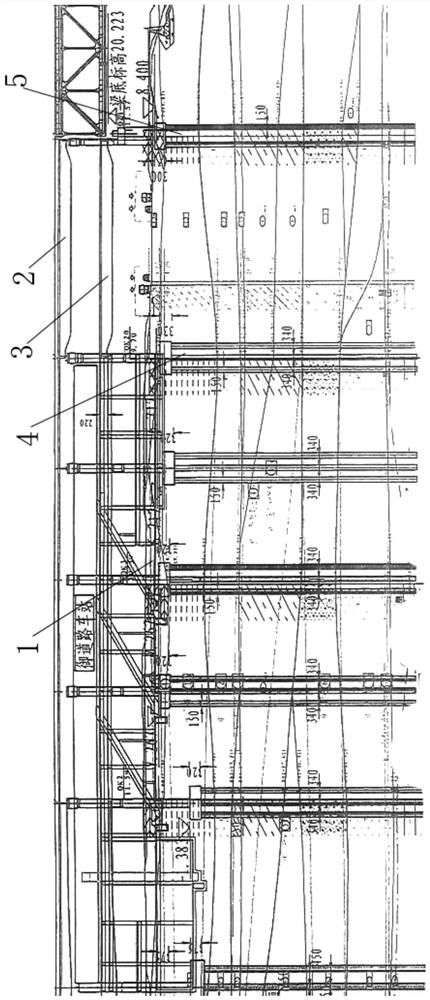

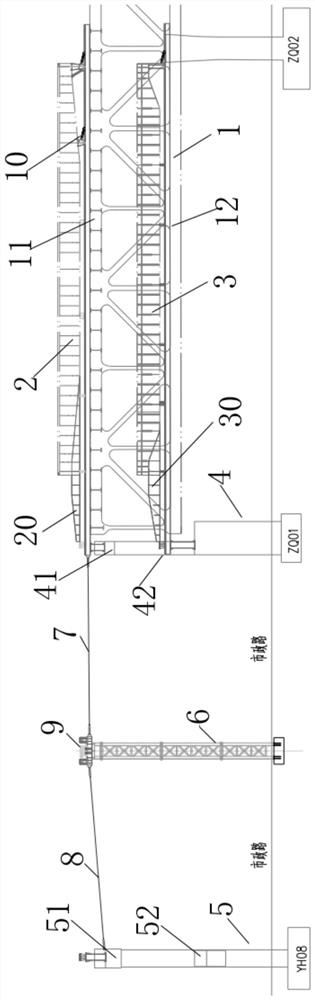

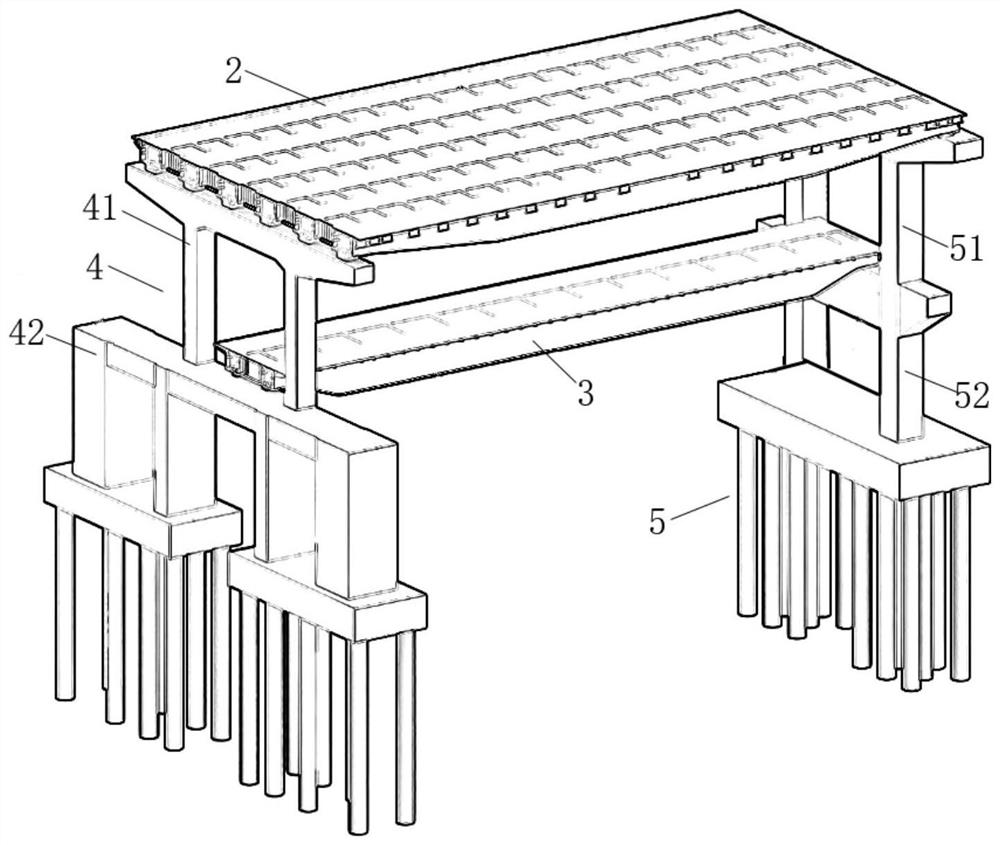

[0056] Such as figure 1 The falling girder structure of the upper and lower double-layer steel bridges of the highway bridge and the railway bridge includes the main bridge 1, the highway composite beam 2, the track composite beam 3, the ZQ1 bridge pier 4, the YH08 bridge pier 5, the support 6, several steel strands-7, Several steel strands 2 8, walking pusher 9, rail clamp 10, highway combined beam guide beam 20 and track combined beam guide beam 30, the ZQ1 pier 4 is connected to the main bridge 1, and the ZQ1 pier 4 and The YH08 pier 5 is on the same straight line, and the ZQ1 pier 4 and the YH08 pier 5 are respectively located on both sides of Shishi Road. The lower steel truss bridge 12, the ZQ1 pier 4 is divided into ZQ1 upper pier 41 and ZQ1 lower pier 42, the YH08 pier 5 is divided into YH08 upper pier 51 and YH08 lower pier 52, and the support 6 is divided into highway composite beam support Frame 61 and track combination beam support frame 62, the upper end of descr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com