Upper air intake furnace end and combustor with same

A technology for a blast stove and a burner base, which is applied in the field of kitchen utensils, can solve the problems of reducing work efficiency, increasing costs, reducing combustion efficiency, etc., and achieves the effects of reducing friction, reducing costs, and improving combustion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

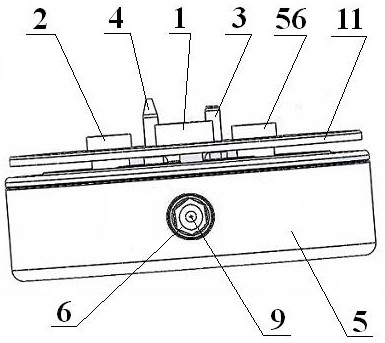

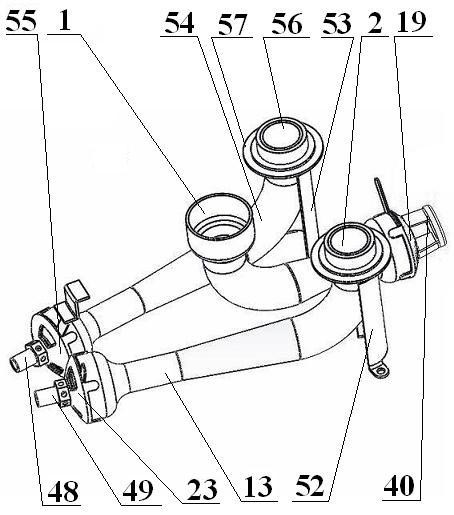

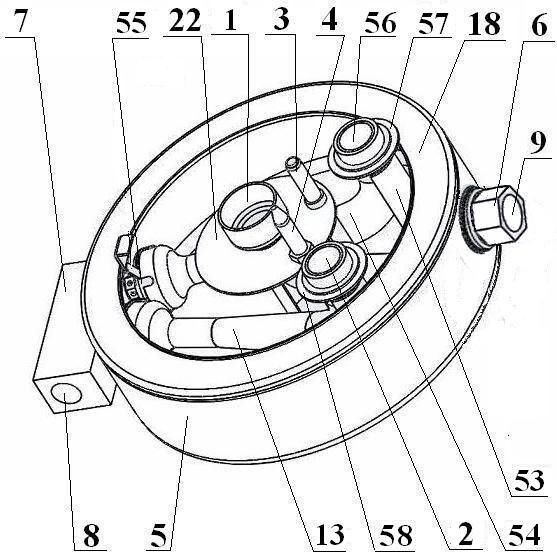

[0033]Embodiment 1: A kind of upward air inlet burner, including burner base 5, central injection tube 25, outer injection tube A13, outer injection tube B54, ventilation seat A6, ventilation seat B7, said burner base 5 is Round cup shape, including annular side walls and circular bottoms connected with the same body, A hole 44, B hole 46, C hole 47 are provided on the side wall of the burner seat 5, and the B hole 46 and C hole 47 is respectively provided with the inner thread that is adapted to the outer thread of the air inlet end of the outer nozzle B48 and the outer nozzle C49. Flared, and respectively fixedly connected to the center damper 19, the outer damper B23, the outer damper C55, the mounting bracket C40 includes an annular body 41 and several connecting pins 42 connected with it, the annular body 41 is provided with an internal Threaded connecting holes 43, several connecting pins 42 are welded with the central damper 19, the central injection pipe 25 is welded w...

Embodiment 2

[0038] Embodiment 2: A kind of burner, on the basis of embodiment 1, will be provided with the outer fire cover seat 10 of outer A pipe 14 and outer B pipe 59 on described secondary air dividing plate 11, and make The outer A tube 14 is inserted into the outlet port 2 of the outer injection A tube, the outer B tube 59 is inserted into the outer injection B tube outlet 56, and the outer fire cover is placed on the outer fire cover seat 10 , and then place the inner fire cover on the gas outlet end 1 of the central injection tube.

[0039] The outer fire cover includes an annular outer lower fire ring 29 formed by casting or stamping stainless steel and an annular outer upper fire ring 28 formed by casting or stamping stainless steel and placed on the outer lower fire ring 29. The outer fire lower ring 29 includes an inner ring A body 32, an upper ring A body 33 and an outer ring A body 34 connected in sequence, and the upper ring A body 33 is provided with several upwardly prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com