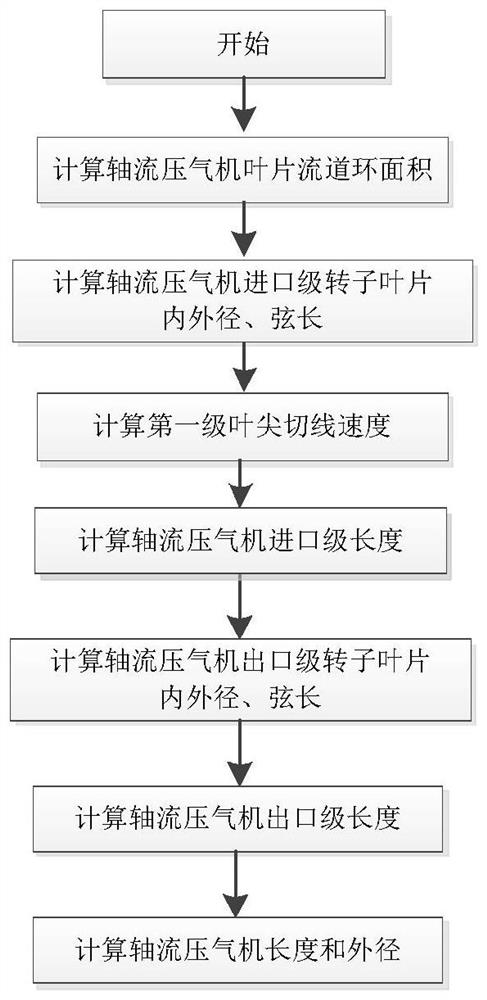

Axial flow compressor size calculation method considering blade mounting angle

A technology for installing axial flow compressors and blades, applied in complex mathematical operations, design optimization/simulation, geometric CAD, etc., can solve problems such as insufficient precision, large calculation errors, and inaccurate dimensions, so as to facilitate optimization iterations and shorten design The effect of the iteration cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

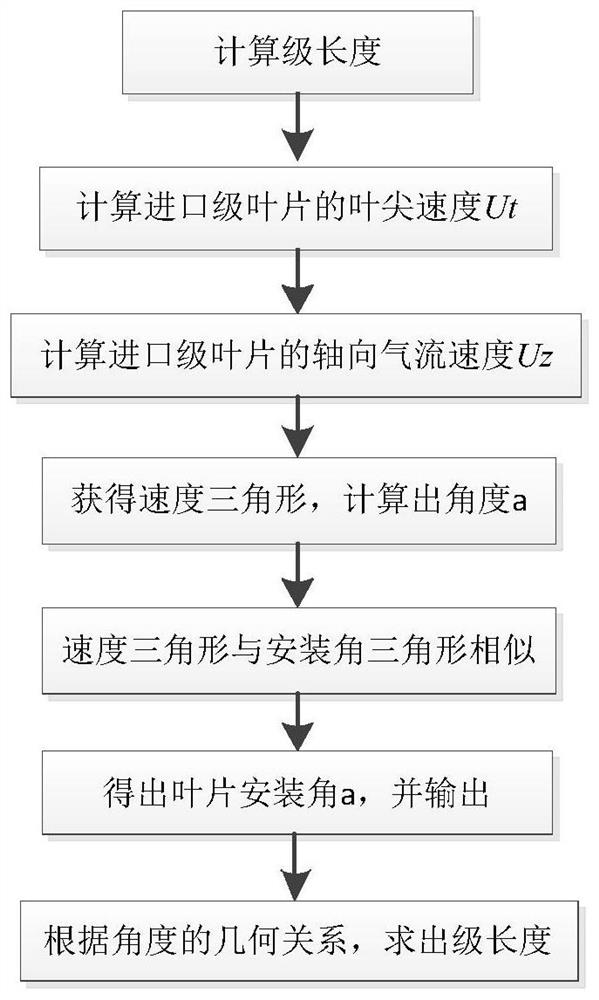

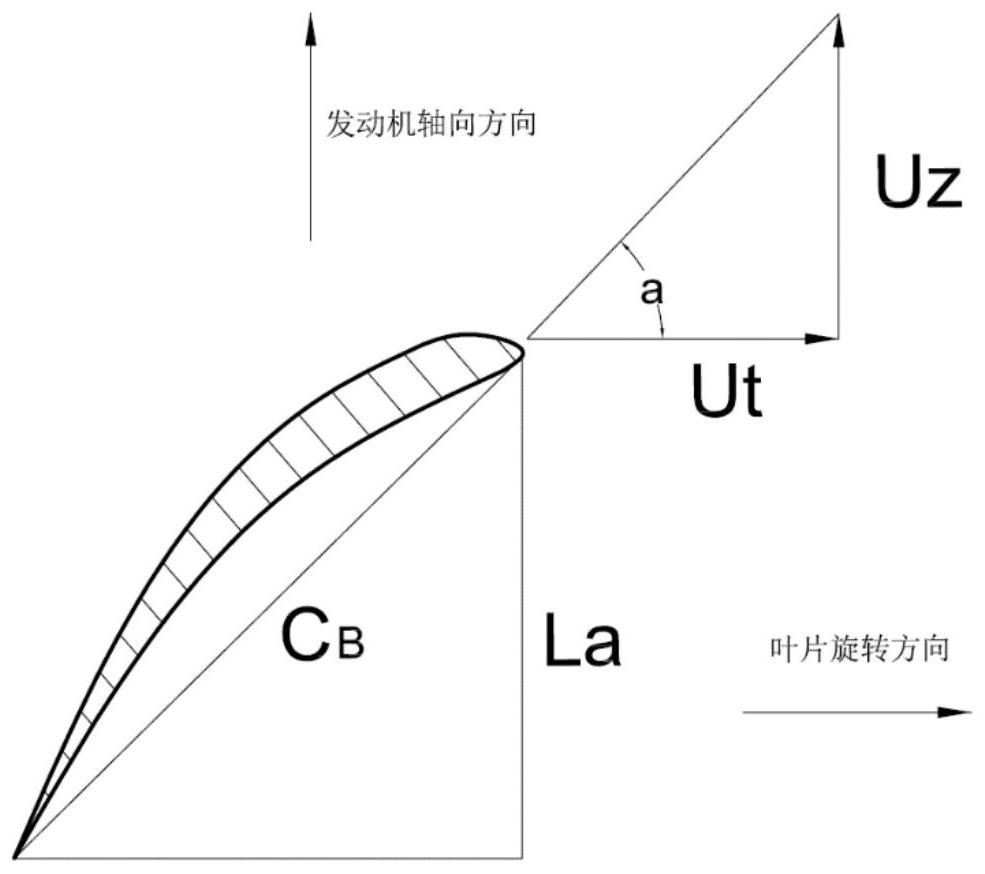

[0069] Embodiment 1: A method for calculating the size of an axial flow compressor with equal inner diameters considering the installation angle of the blades, comprising the following steps:

[0070] 101. According to the section parameters of the inlet stage of the axial flow compressor with equal inner diameters, the section parameters of the inlet stage rotor blades and the outlet stage of the axial flow compressor include: the Mach number of the inlet stage rotor blades is Ma in , the Mach number of the rotor blade at the exit stage is Ma out ; The rotor blade flow rate at the inlet stage is W in , the rotor blade flow rate at the outlet stage is W out ; The total temperature of the rotor blades at the inlet stage is T in , the total temperature of the rotor blades at the outlet stage is T out ; The total pressure of the rotor blades at the inlet stage is P in , the total pressure of the rotor blades at the outlet stage is P out ; The oil-gas ratio of the inlet stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com