Cable bridge

A cable bridge and bridge technology, applied in the direction of electrical components, etc., can solve the problem that the cable bridge is difficult to practice and automatically lay cables, etc., and achieve the effects of reducing labor costs, good applicability, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

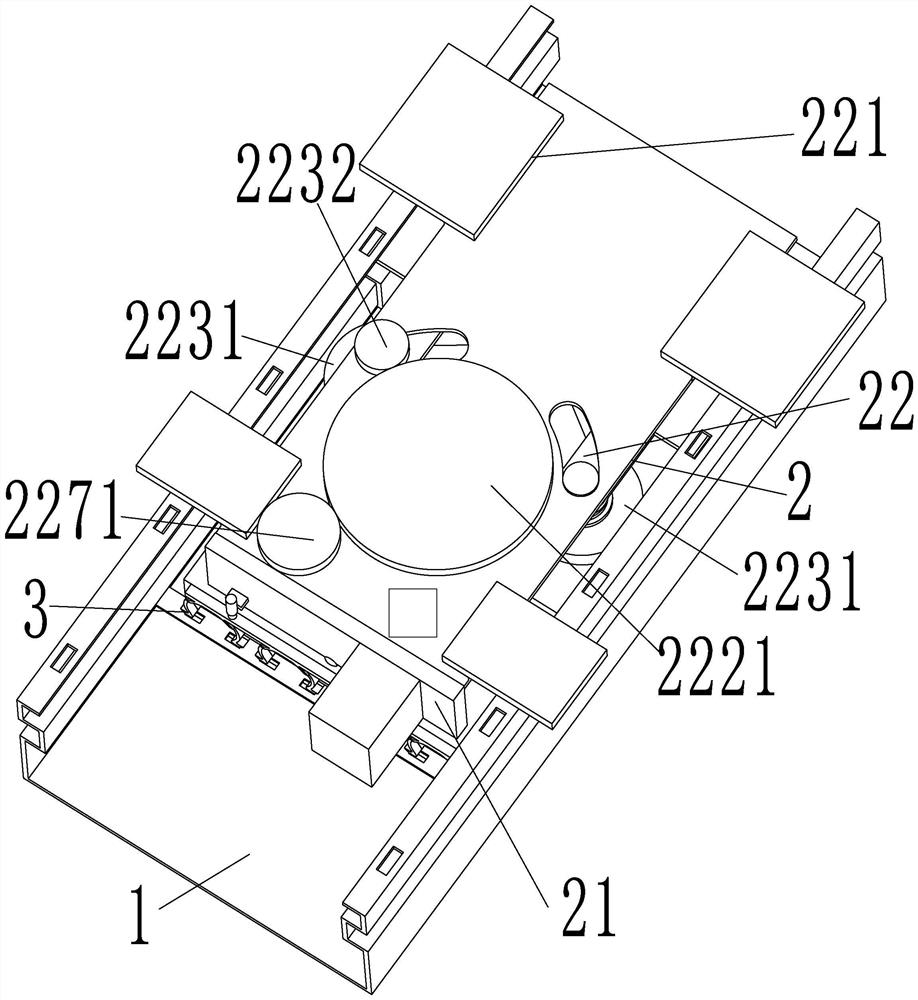

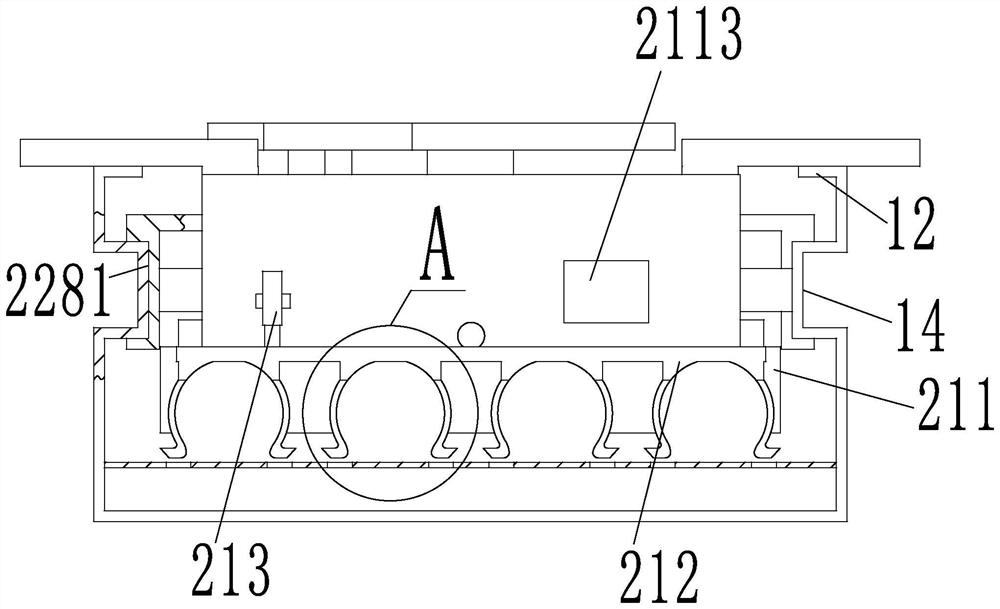

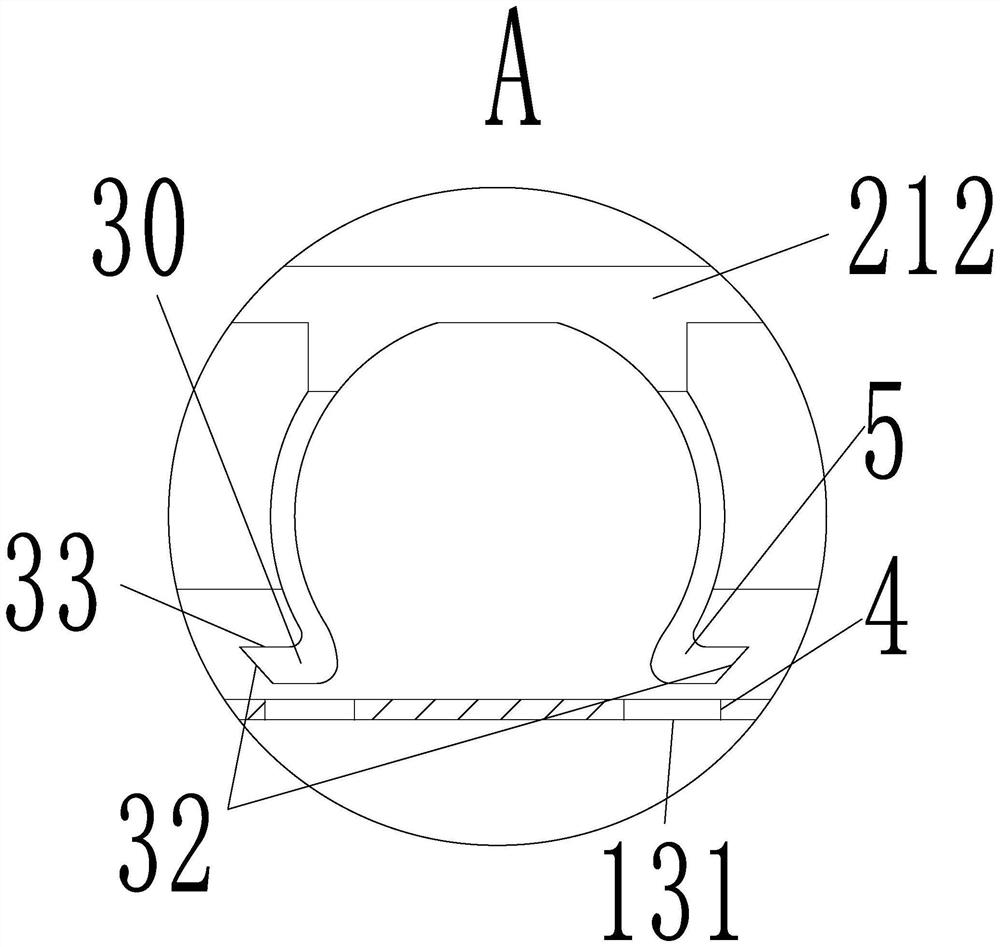

[0027] Depend on Figure 1 to Figure 9 As shown, the cable bridge of the present invention includes a bridge body 1, a wiring device 2 and a plurality of fixing rings 3; There are a plurality of reinforcing ribs 13 for fixing cables, the length direction of each reinforcing rib 13 is parallel to the width direction of the bottom plate 101, and each reinforcing rib 13 is arranged in groups of two along its length direction. A plurality of fixing grooves 131; each fixing ring 3 is provided with an opening, and both sides of the opening are provided with buckle parts 30;

[0028] The specific wiring process is as follows:

[0029] 1. Preparatory work: When laying cables, first manually pull out the starting ends of multiple cables from the pay-off device, and fix them on the front end of the bridge frame in advance, and then set the sa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap