Intelligent electromagnetic welding machine monitoring device

A technology of monitoring device and welding machine, which is applied in the direction of cooling/ventilation/heating transformation, etc. It can solve the problems of fixed mode use, equipment damage, and the failure of automatic reporting of location information by welding machines, so as to achieve the effect of increasing heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

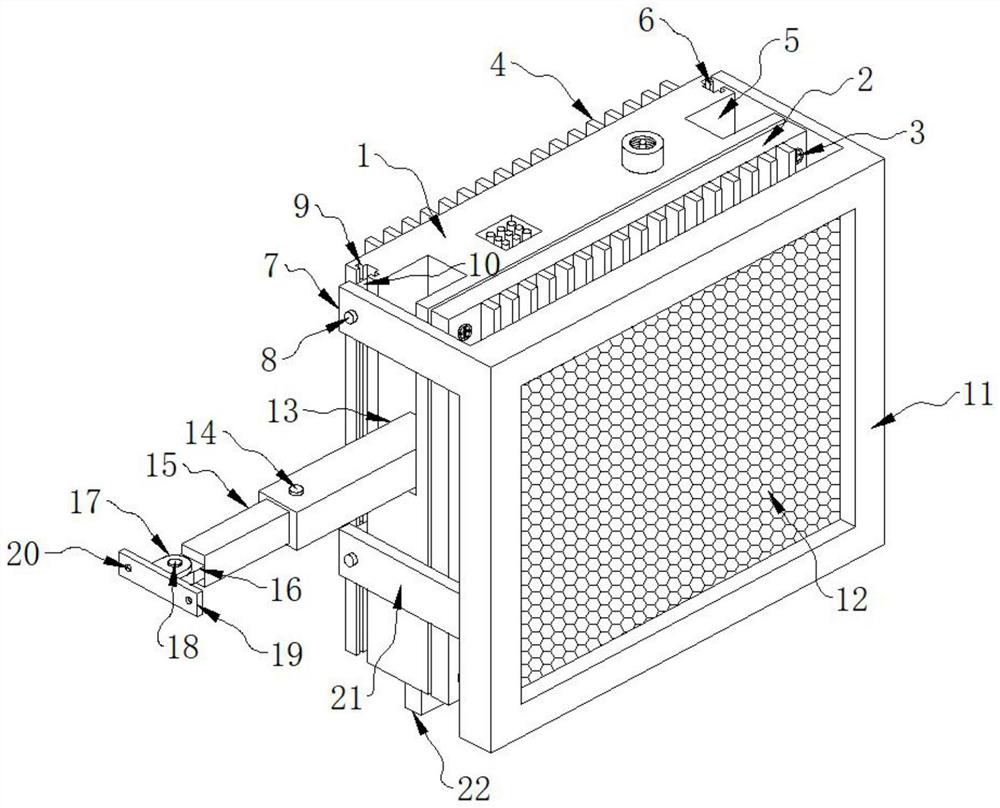

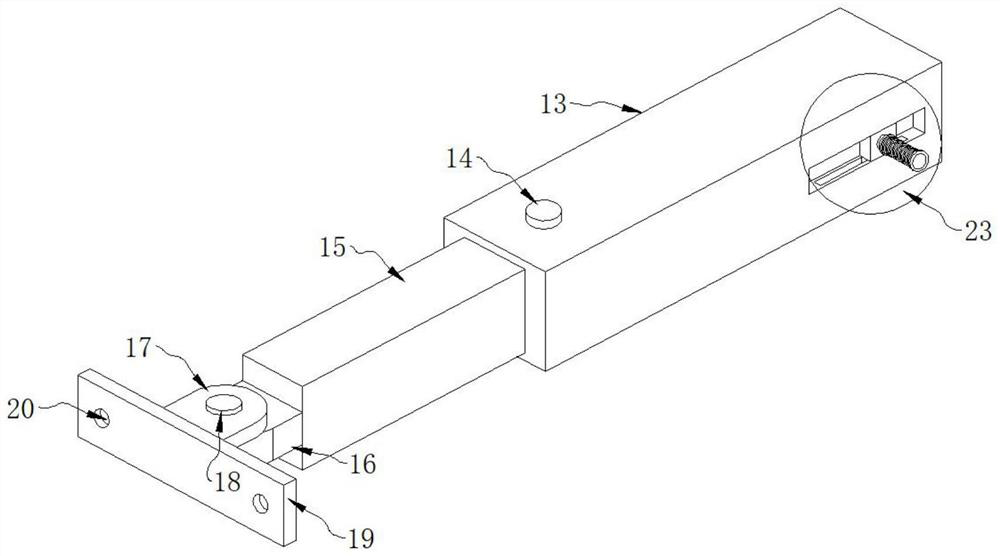

[0029] As a preferred embodiment of the present invention, a cooling plate 22 is installed on the bottom of the fixed box 1, and an oblique hole 37 is opened on the cooling plate 22, and connecting devices 23 are installed on both sides of the fixing rod 13, so that The fixing rod 13 is installed inside the opening 5 through the connecting device 23 .

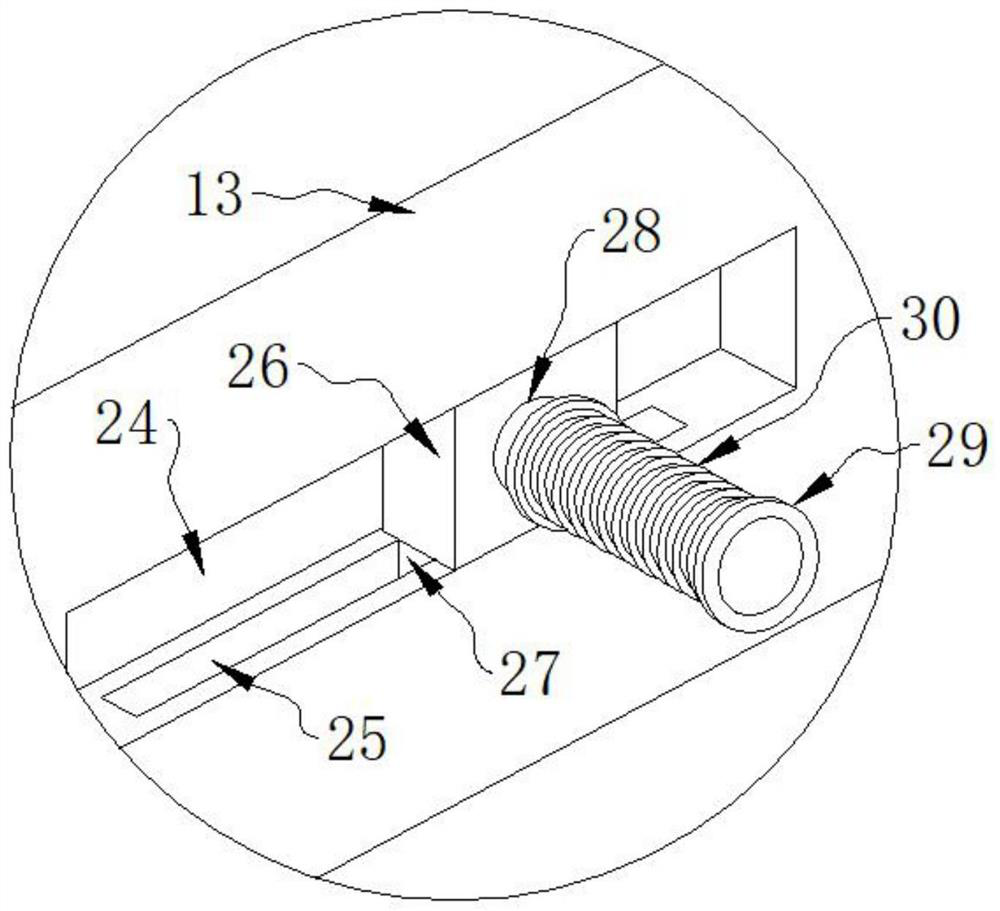

[0030] As a preferred embodiment of the present invention, the connection device 23 includes a chute 24, a slider 26 is installed inside the chute 24, and a block 27 is installed on the slider 26, so A groove 25 is formed on the inner wall of the first chute 24, and the clamping block 27 is installed in the groove 25.

[0031] As a preferred embodiment of the present invention, an inner rod 28 is fixed on the slider one 26, an outer rod 29 is fixed on the inner rod 28, and a torsion spring is installed between the outer rod 29 and the inner rod 28. 30, the two ends of the torsion spring 30 are respectively fixed on the inner r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com