Novel hearth cooling structure and mounting method thereof

A technology of a cooling structure and an installation method, applied in the direction of a cooling device and the like, can solve the problems of low heat transfer efficiency, complex design structure, and difficult installation of a hearth cooling wall, and achieve the effects of good cooling effect, low cost, and convenient and fast installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

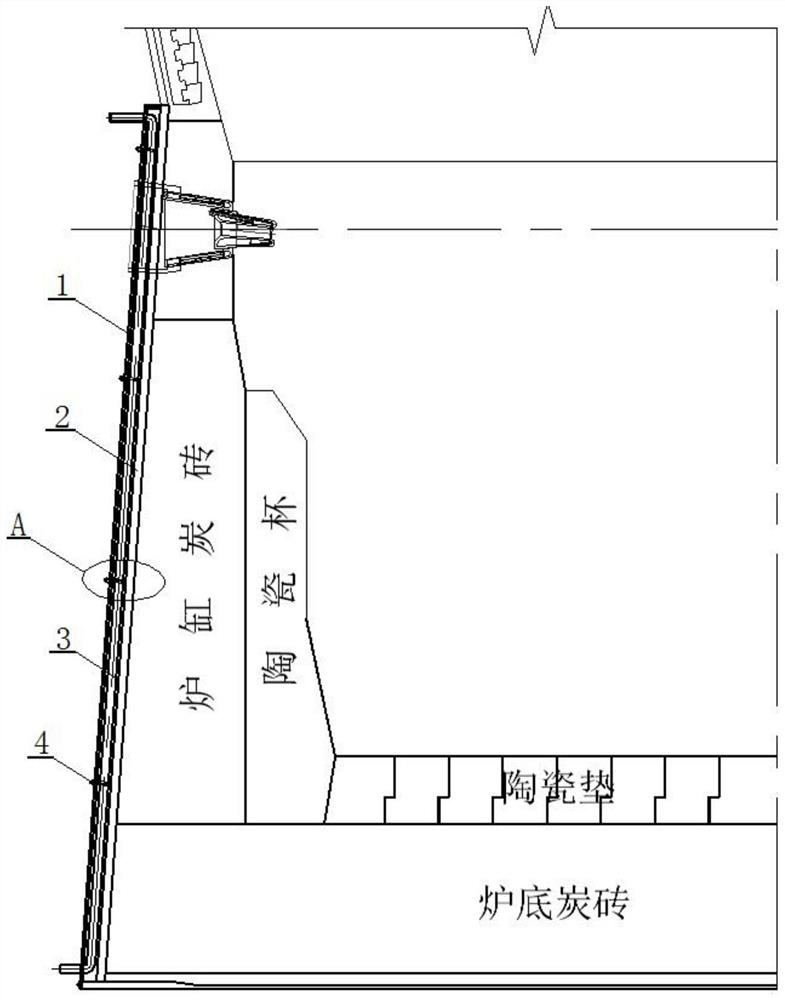

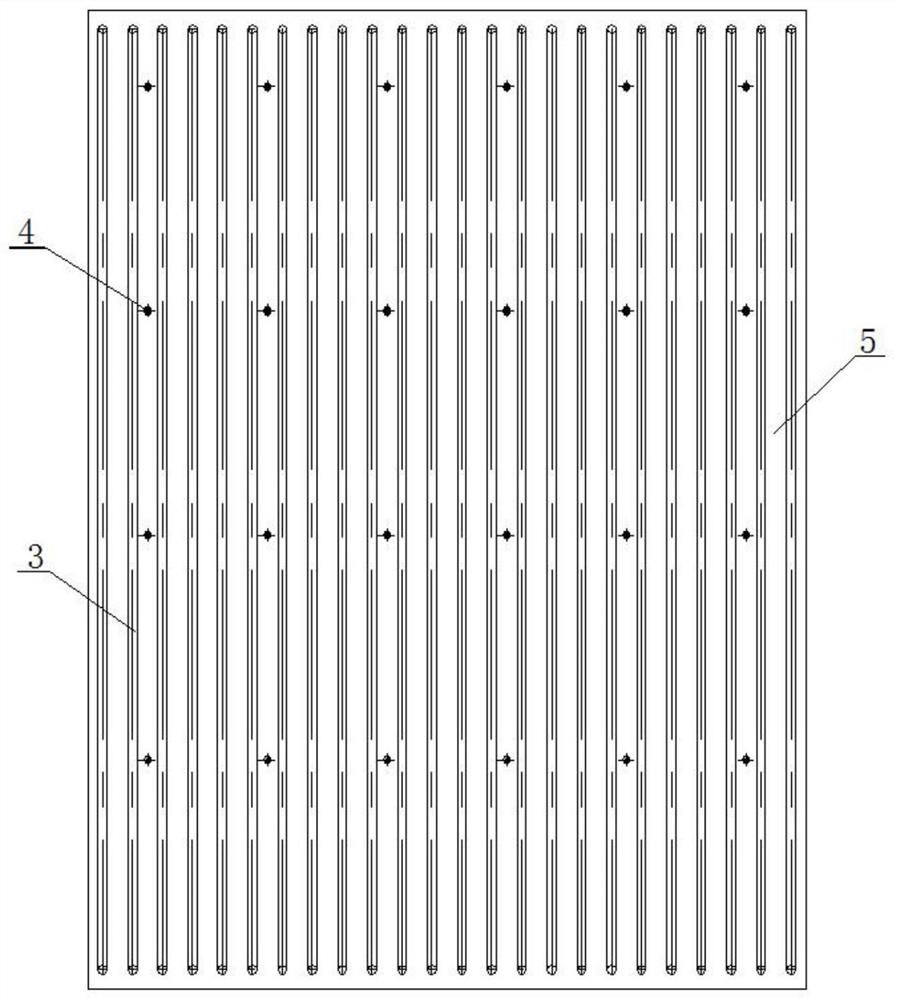

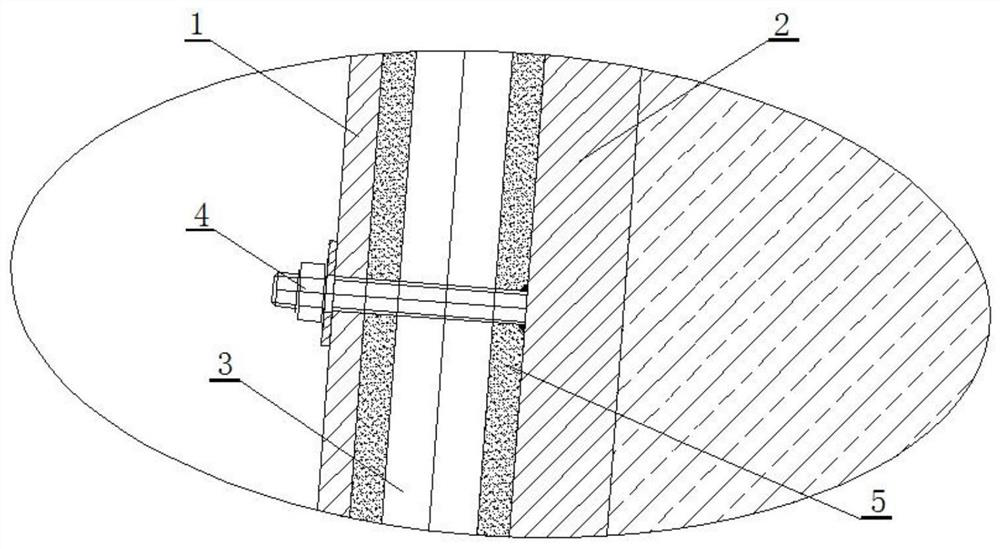

[0034] like Figures 1 to 3 As shown, a new hearth cooling structure is arranged on the outer periphery of the hearth carbon brick of the blast furnace, including the inner furnace shell 2 and the outer furnace shell 1, and the two are fixedly connected by a plurality of fixing parts 4; the inner furnace shell 2 and the outer furnace shell A plurality of water-cooled pipes 3 are laid between the shells 1, and the outside of the water-cooled pipes 3 is filled with heat-conducting refractory materials 5; the two ends of each water-cooled pipe 3 are respectively arranged outside the upper and lower ends of the hearth cooling structure, so that the whole Compared with the prior art, the layout can effectively reduce the cooling blind area, increase the cooling specific surface area, and reduce the opening of the furnace shell; when installing, firstly install the inner furnace shell 2 along the outer periphery of the blast furnace hearth, and then install the water-cooled tube 3 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com