Cast-in-place slurry state data acquisition device and monitoring system

A technology of state data and acquisition device, applied in the field of construction, can solve the problems of the detection influence of gypsum wall quality, time-consuming, large data error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

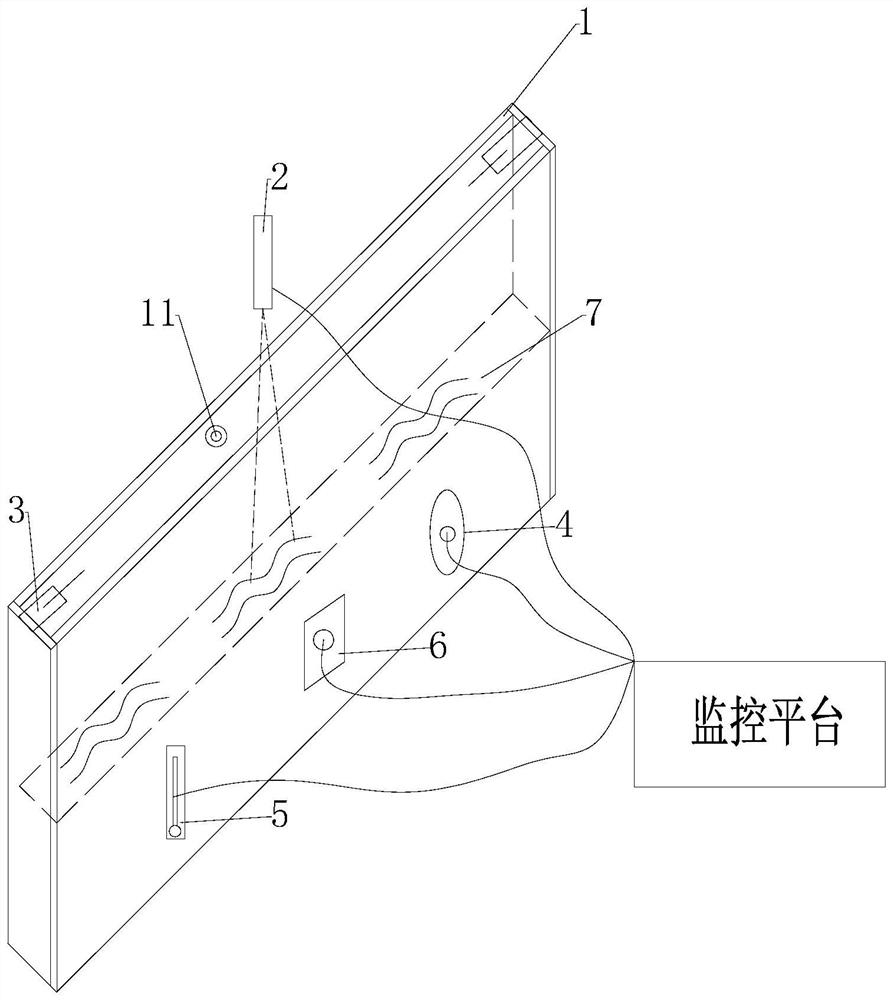

[0046] Such as figure 1 As shown, the present invention provides a cast-in-place slurry state data acquisition device, including a mold 1 , a visual sensor 2 , a through-beam laser sensor 3 , an inclination sensor 4 , a temperature sensor 5 and a pressure sensor 6 .

[0047] The mold 1 is surrounded by templates to form a cuboid with upper and lower openings in the mold cavity. The mold cavity is used for pouring slurry, and a pouring port 11 is arranged above the template. Mouth 11.

[0048] The visual sensor 2 is installed above the mold 1 to collect the actual reaction state of the slurry in the mold cavity. In this embodiment, the visual sensor 2 is installed in the middle of the template on both ends, and the visual sensor 2 is a camera. . When pouring slurry into the mold cavity, since the surroundings of the mold cavity are closed, it is impossible to know the reaction state of the slurry in the mold cavity. By installing a visual sensor 2, the slurry in the mold cavi...

Embodiment 2

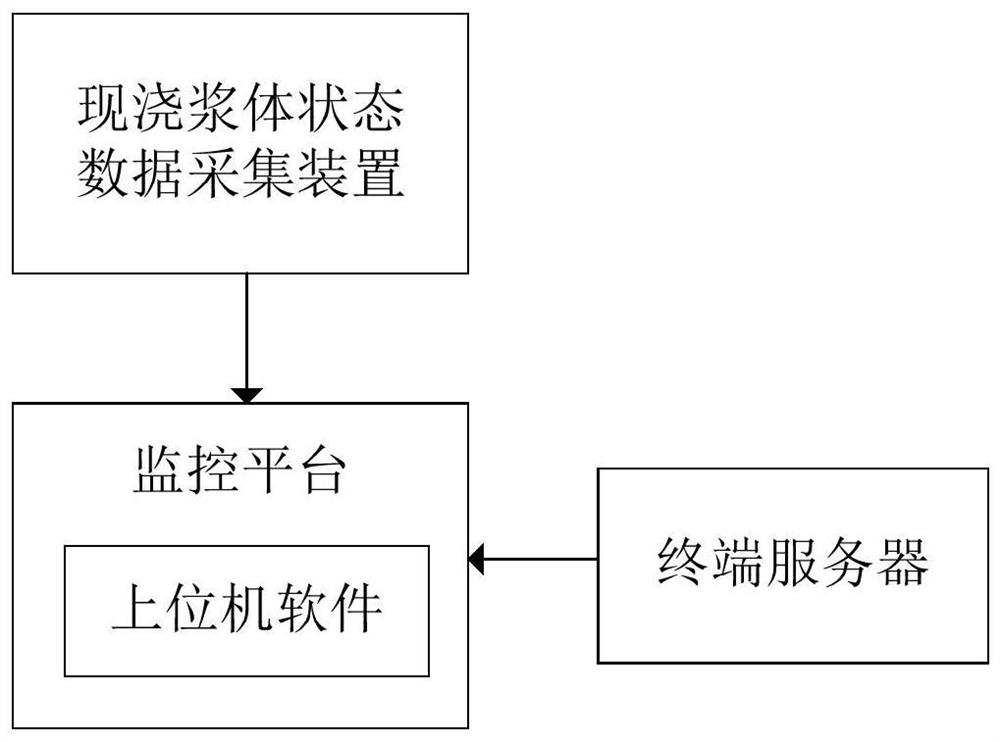

[0055] Such as Figure 2-3 As shown, the present invention provides a cast-in-place slurry state monitoring system, including the cast-in-place slurry state data acquisition device, and also includes a terminal server and a monitoring platform;

[0056] PC software is integrated in the monitoring platform;

[0057] The terminal server is used to store the standard response state of the slurry;

[0058] The monitoring platform is used to receive the actual reaction state of the slurry collected by the visual sensor in the mold cavity, and the host computer software compares the actual reaction state with the standard reaction state of the slurry, and judges whether the current pouring situation meets the standard. Achieve real-time monitoring and feedback of slurry reaction status;

[0059] The monitoring platform is used to receive the light intensity change signal collected by the laser sensor when the slurry overflows the pouring port, and the host computer software contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com