Thermocouple mechanism for multi-module high-temperature ceramic firing

A technology of high-temperature ceramics and thermocouples is applied in the field of thermocouple mechanisms for multi-module high-temperature ceramics firing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

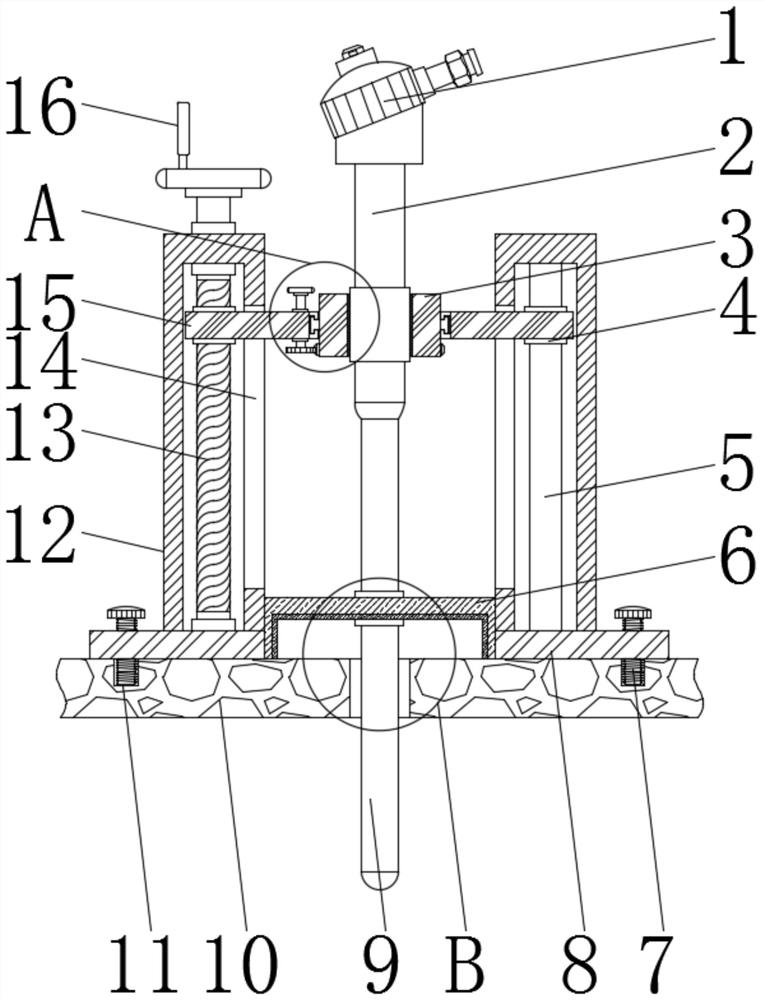

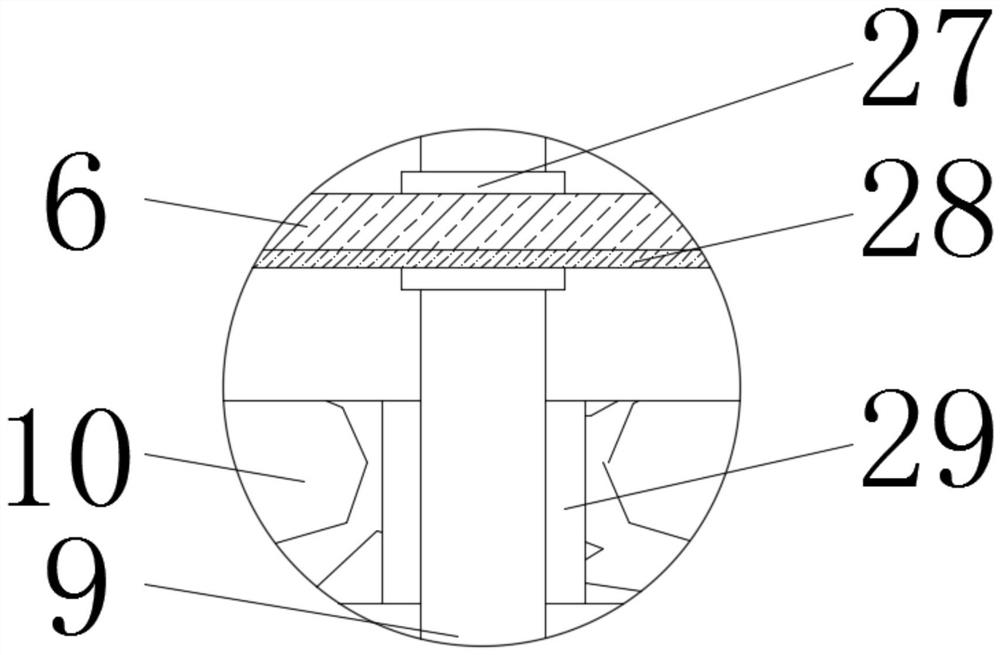

[0033] Embodiment 1, a thermocouple mechanism for firing multi-module high-temperature ceramics, including a junction box 1, an insulating sleeve protection tube 2, a hot electrode 9, a fixing plate 8 and a furnace wall 10, and one end of the junction box 1 is connected and installed with an insulating sleeve protection The tube 2, and the bottom end of the insulating sleeve protection tube 2 is connected with a thermal electrode 9, a wall hole 29 is opened on the furnace wall 10, and a thermal electrode 9 is inserted in the wall hole 29, and the top surface of the fixed plate 8 is symmetrically installed with an adjustable Box 12, and the opposite side of the adjustment box 12 is symmetrically provided with a lifting groove 14, and a lifting plate 15 is embedded in the lifting groove 14, a nut 30 is installed on one end of the lifting plate 15, and a threaded rod shaft is installed in the cavity of an adjusting box 12 13, and the threaded rod shaft 13 and the nut 30 are engage...

Embodiment 2

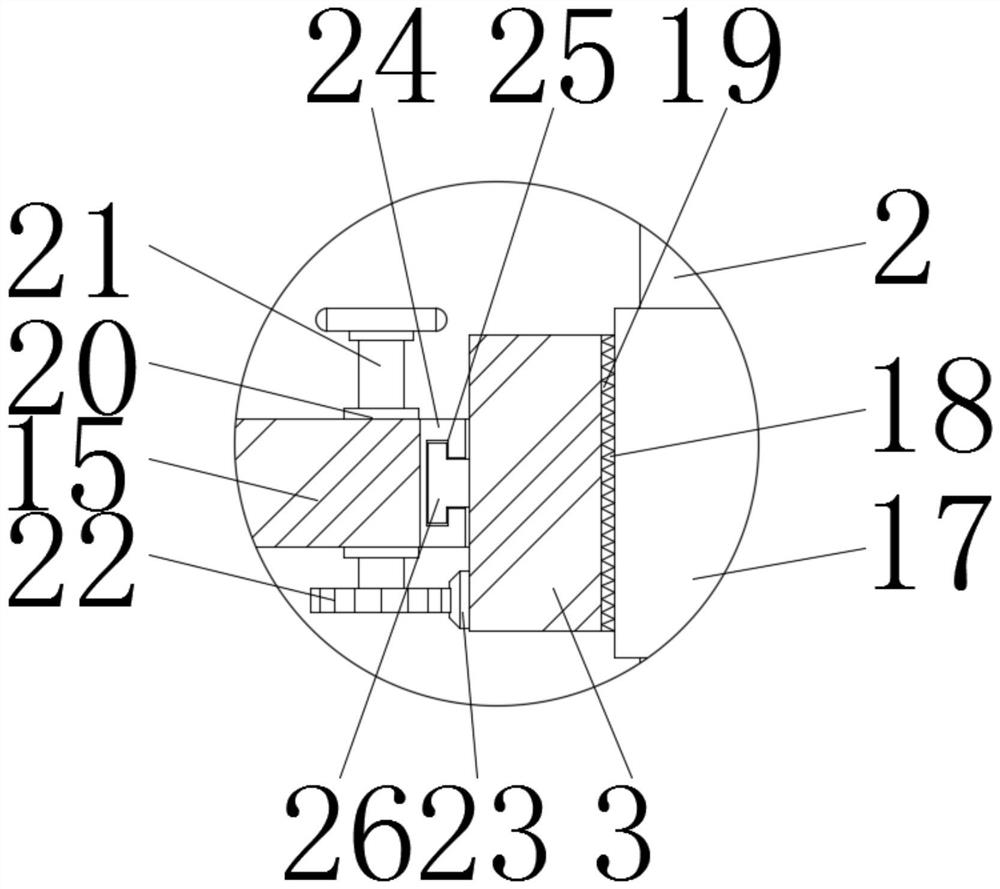

[0034]Embodiment 2, a fixed ring 24 is fixedly installed in the center of the lifting plate 15, and an annular chute 25 is provided inside the fixed ring 24, and an annular slider 26 is embedded in the annular chute 25, and the annular slider 26 is fixedly installed on the mounting ring. 3 the outer wall, and the inner wall of the installation ring 3 is provided with an internal thread 19, the side wall of the insulating sleeve protection tube 2 is fixedly installed with a connecting ring 17, and the side wall of the connecting ring 17 is provided with an external thread 18, and the external thread 18 and the internal thread 19 are engaged with each other It plays the role of installing and fixing a thermocouple mechanism for firing multi-module high-temperature ceramics.

Embodiment 3

[0035] Embodiment three, the ring gear 23 is installed on the bottom end of the outer wall of the installation ring 3, the installation bearing 20 is installed on the lifting plate 15, and the adjustment shaft 21 is installed in the installation bearing 20, and a gear 22 is installed on one end of the adjustment shaft 21, and the gear 22 and The ring gears 23 mesh with each other to achieve the purpose of adjusting the use angle of the junction box 1, and there is no need to disassemble and reinstall a thermocouple mechanism for firing multi-module high-temperature ceramics in this process, thereby providing a multi-module high-temperature ceramic The wiring work of the thermocouple mechanism for firing brings great convenience.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com