Thrust washer

A technology of thrust washers and inner rings, applied to mechanical equipment, connecting components, etc., can solve problems such as time-consuming and labor-intensive, cumbersome and labor-intensive work processes, and affect work efficiency, and achieve the effects of convenient operation, increased automation, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

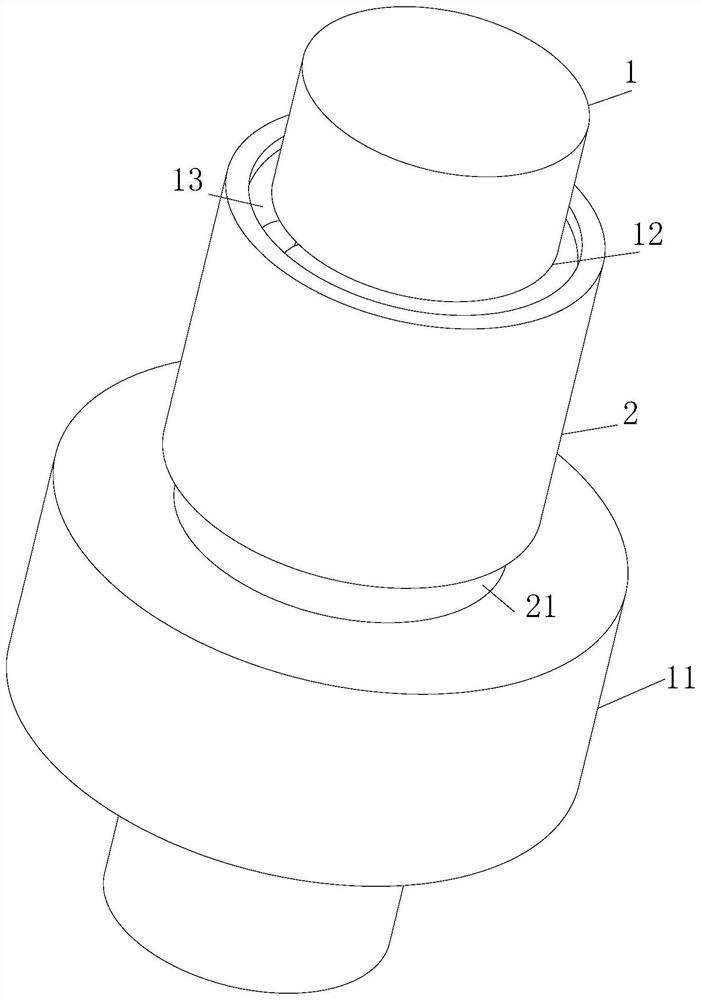

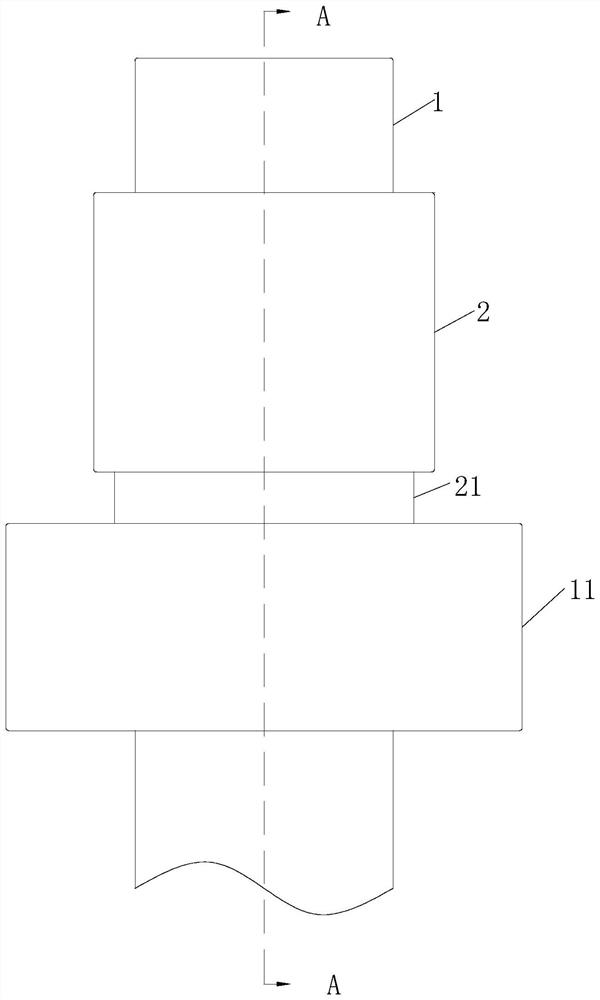

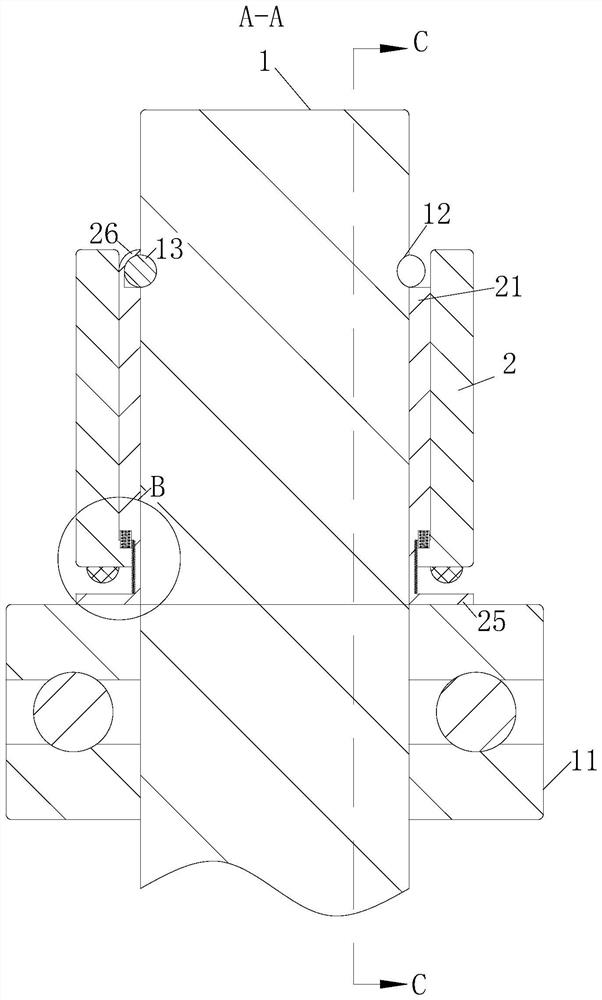

[0033] A thrust washer comprising:

[0034] Inner ring 21, the inner ring 21 is in the shape of an annular plate, the inner diameter of the inner ring 21 is equal to the outer diameter of the spline shaft 1, and the outer diameter of the inner ring 21 is not smaller than the outer diameter of the installed axial wire retaining ring;

[0035] Outer ring 2, the outer ring 2 is in the shape of an annular plate, the inner diameter of the outer ring 2 is not smaller than the outer diameter of the installed axial steel wire retaining ring, and the inner wall of the outer ring 2 is in contact with the outer wall of the inner ring 21 connect;

[0036] During work, the thrust washer of the prior art is installed on the lower part of the steel wire washer for the shaft and the upper end of the thrust washer is clamped with the steel wire retaining ring 13 for the shaft. The steel wire retaining ring 13 is disengaged, and then the shaft steel wire retaining ring 13 is removed, and then ...

Embodiment 2

[0041] Compared with embodiment 1, the difference is:

[0042] In this embodiment, the outer ring 2 and the inner ring 21 are screwed 24 .

[0043] When working, the inner wall of the outer ring 2 and the outer wall of the inner ring 21 are connected by threads. When the worker removes the steel wire retaining ring 13 for the shaft, he only needs to rotate the outer ring 2 so that the outer ring 2 moves downward relative to the inner ring 21. It has the advantages of simple structure, reliable connection, convenient assembly and disassembly, etc.

Embodiment 3

[0045] Compared with embodiment 1, the difference is:

[0046] In this embodiment, the axial position between the inner ring 21 and the outer ring 2 is connected by a tension spring 22 .

[0047] When working, the staff moves the outer ring 2 downwards to expose the steel wire retaining ring 13 for the shaft. When loosening, the tension spring 22 makes the outer ring 2 rewrap the steel wire retaining ring 13 for the shaft, thereby facilitating the alignment of the steel wire washer for the shaft. It can be disassembled, and at the same time, it will play a role in slowing down the vibration when it is subjected to axial force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com