Rotary multi-station blanking device for computer mainboard manufacturing

A computer motherboard and rotary technology, applied in metal processing and other directions, can solve the problems of easy accidental injury to workers, inconvenient motherboard replacement, and easy breakage of the motherboard, so as to prevent damage, facilitate collection, and avoid manual picking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

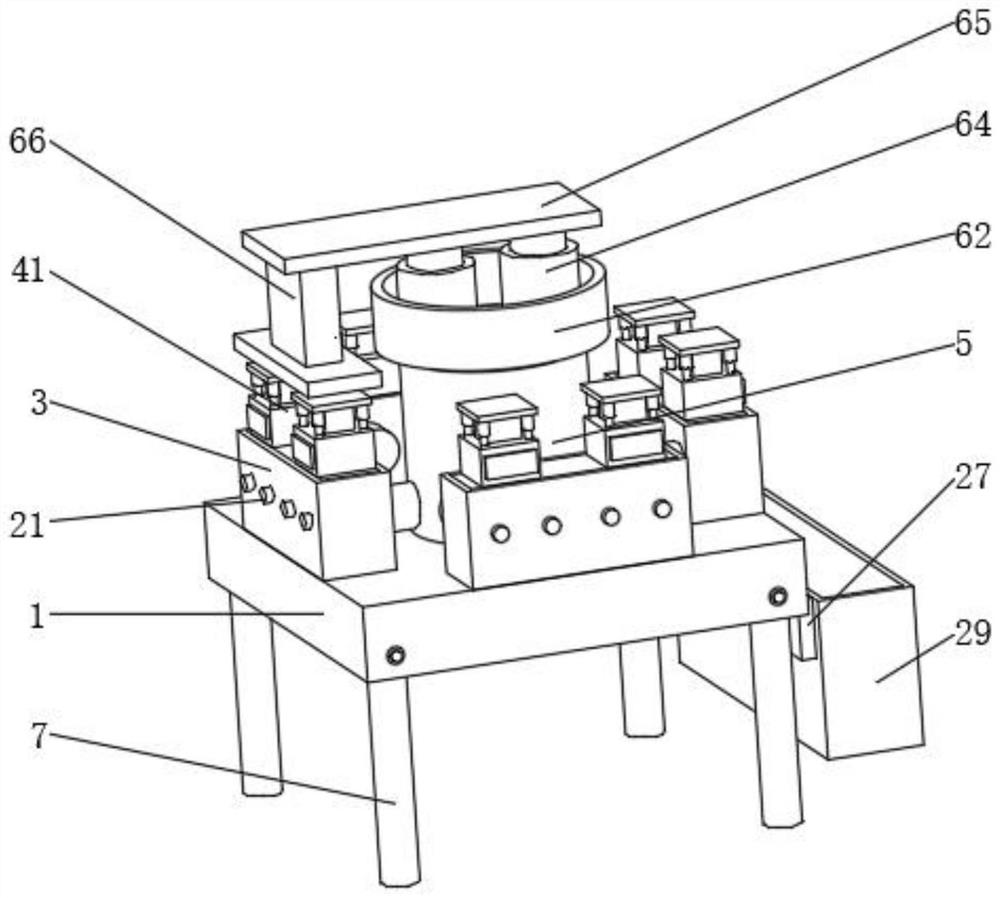

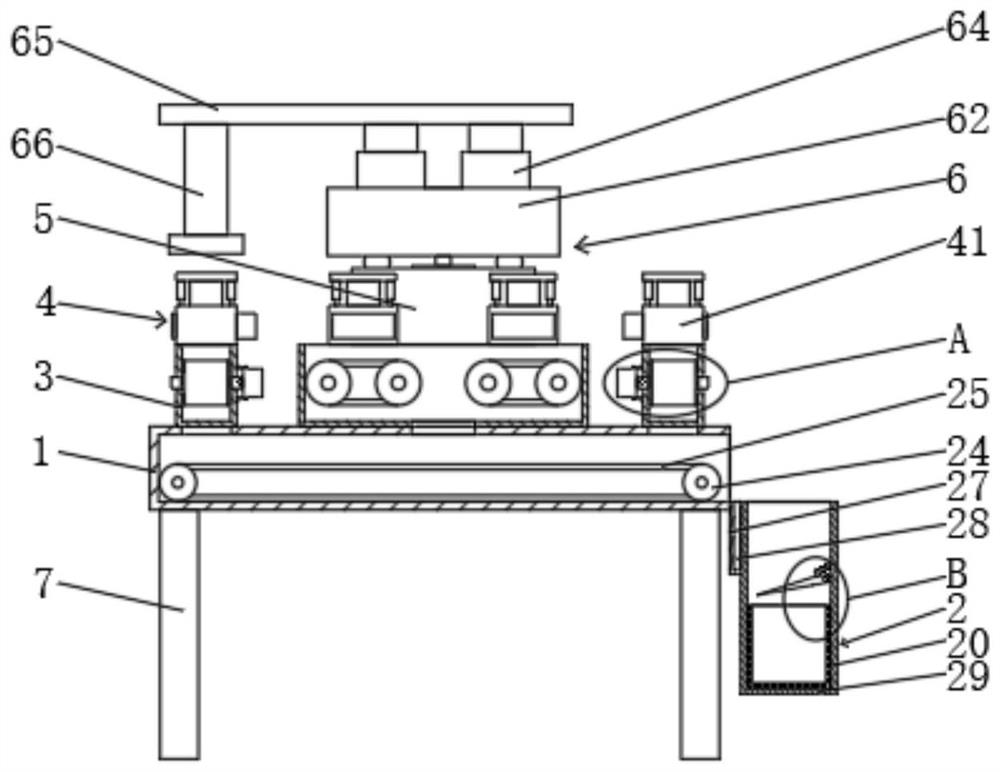

[0027] A rotary multi-station punching device used in the manufacture of computer motherboards, comprising an operating table 1, a receiving mechanism 2, a support box 3, a punching mechanism 4, a rotating seat 5, a rotating mechanism 6, and supporting legs 7, the The operating table 1 is provided with a receiving mechanism 2, and the operating table 1 is fixedly connected with a support box 3. The number of the supporting boxes 3 is four, and the four supporting boxes 3 are uniformly placed on the operating table 1. Distribution, the support box 3 is provided with a punching mechanism 4, the operating table 1 is fixedly connected with a rotating seat 5, the rotating seat 5 is provided with a rotating mechanism 6, and the lower end of the operating table 1 is fixedly connected with Four evenly distributed support legs 7.

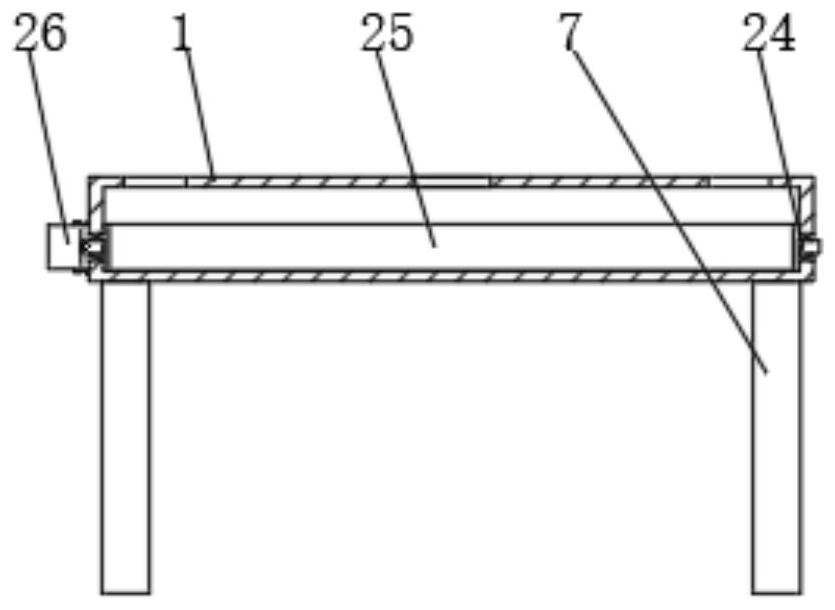

[0028] Wherein, the material receiving mechanism 2 includes a drive wheel 21, a material guide belt 22, a gear motor 1 23, a material guide roller 24, a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com