Tension peeling testing machine

A testing machine and tension technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc. It can solve the problems that the rope cannot be in a horizontal state and cannot move height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

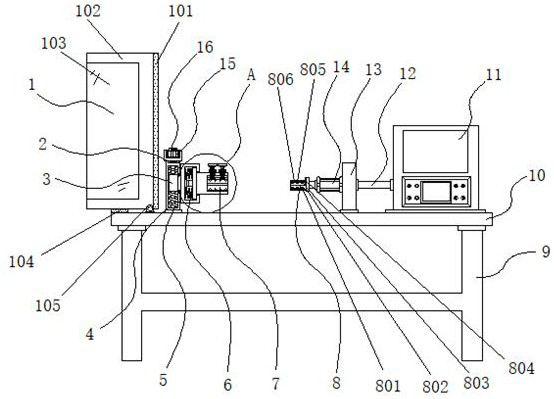

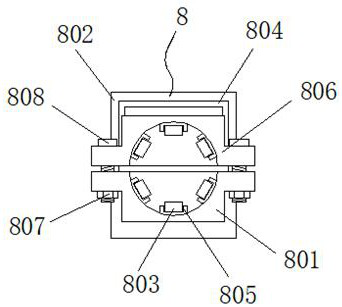

[0035] Example 1: See Figure 1-6 , a tensile peel testing machine, comprising a tensile peel testing machine, including a bracket 9 and a workbench 10, the top of the bracket 9 is fixedly connected with a workbench 10, and the top of the workbench 10 is fixedly connected with a mounting column 13, and the workbench 10 One side of the top is fixedly connected with a controller 11, and one side of the installation column 13 is fixedly connected with a hydraulic cylinder 14, the type of the hydraulic cylinder 14 is HOB, and the output end of the hydraulic cylinder 14 is provided with an anti-off structure 8, and the hydraulic cylinder 14 One side is fixedly connected with a connection line 12, the connection line 12 runs through the mounting column 13 and is fixedly connected with the controller 11, a protective structure 1 is provided on one side of the top of the workbench 10, and a trigger mechanism 6 is provided on the top of the workbench 10, and the trigger mechanism 6 One...

Embodiment 2

[0039] Embodiment 2: Protective structure 1 is made up of rubber strip 101, protective cover 102, window 103, placement pad 104 and hinge block 105, and hinge block 105 is fixedly connected to the two ends of workbench 10 top side, and one end of hinge block 105 is movable Connected with a protective cover 102, one side of the protective cover 102 is fixedly connected with a rubber strip 101, the inside of the protective cover 102 is fixedly connected with a window 103, and the placement pad 104 is fixedly connected to the top side of the workbench 10, and the placement pad 104 and the protective cover 102 active connections;

[0040] The center line of window 103 and the center line of protective cover 102 are on the same horizontal plane, and the height of rubber strip 101 is equal to the height of protective cover 102;

[0041] Specifically, as figure 1 and Image 6 As shown, after the rope is fixed, turn over the protective cover 102 to attach the rubber strip 101 to the...

Embodiment 3

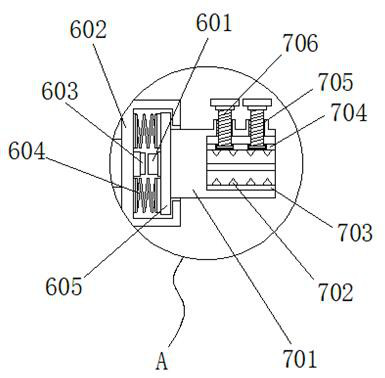

[0042] Embodiment 3: The trigger mechanism 6 is composed of a bump 601, a movable groove 602, a trigger 603, a spring 604 and a limit plate 605. The movable groove 602 is fixedly connected to one side of the threaded sleeve 3, and the inner side of the movable groove 602 A group of springs 604 are fixedly connected to both ends respectively, one side of the spring 604 is fixedly connected to the limiting plate 605, one side of the limiting plate 605 is fixedly connected to a bump 601, and one side inside the movable groove 602 is fixedly connected to a trigger 603;

[0043] The centerline of the bump 601 and the centerline of the trigger 603 are on the same horizontal plane;

[0044] Specifically, as figure 1 , image 3 and Figure 5 As shown, when using this device to detect, one side of the rope is fixed inside the fixed structure 7, and the hydraulic cylinder 14 is activated to pull the rope to the other side through the anti-off structure 8. When the rope breaks, the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com