Grabbing device of aerogel base material loading tool

A grasping device, aerogel technology, applied in the directions of measuring device, transportation and packaging, load hoisting components, etc., can solve the problem of low hoisting efficiency, aerogel base material loading tool can not be reliably hoisted, and the hook is easy to disengage and other problems to achieve the effect of improving production efficiency, reliable hoisting, and preventing shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

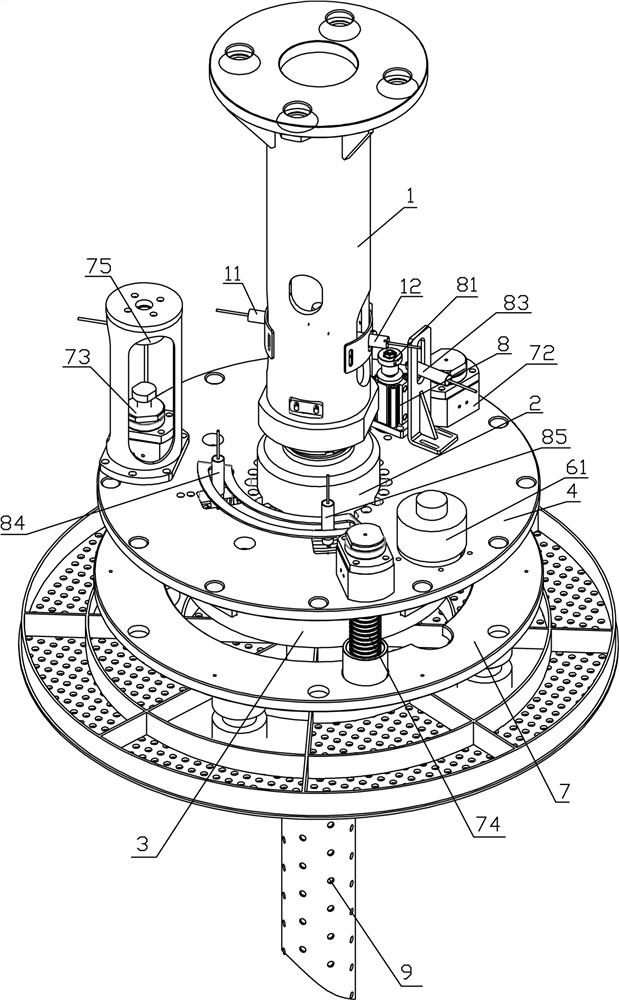

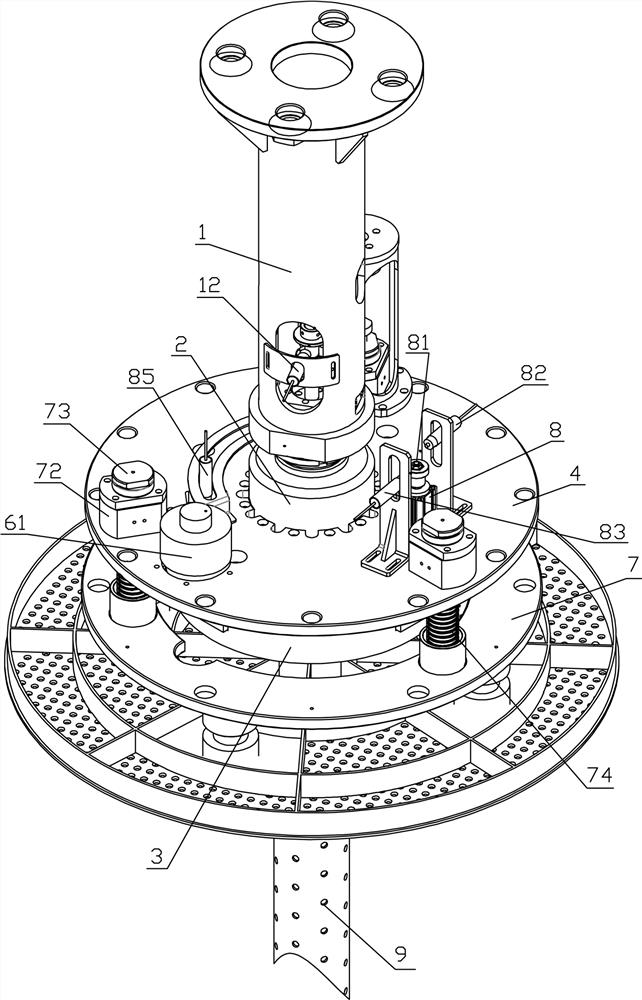

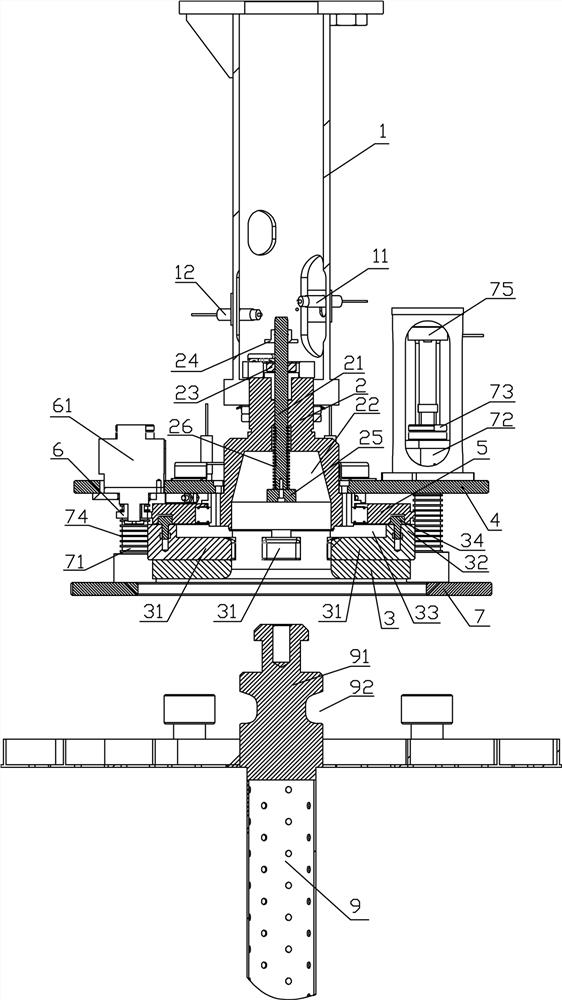

[0022] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

[0023] In order to cooperate with the grabbing device of the present invention, a lifting head 91 needs to be set on the top of the airgel substrate loading tool 9 , and a ring-shaped groove 92 needs to be set on the side wall of the lifting head 91 .

[0024] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7As shown, the grabbing device for the airgel substrate loading tooling includes: a vertically arranged hoisting tube 1, the upper end of the hoisting tube 1 is used to fix the lifting device, and a hoisting seat is fixed on the lower end of the hoisting tube 1 2. The top of the hoisting seat 2 is inserted upward through the lower end of the hoisting pipe 1 and inserted into the hoisting pipe 1. In this embodiment, the top of the hoisting seat 2 is screwed to the lower end of the hoisting pipe 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com