Large-tonnage platform loop wheel machine

A large-tonnage, crane technology, used in cranes, walking bridge cranes, transportation and packaging, etc., can solve the problems of poor crane stability, troublesome construction, and inappropriate hoisting, so as to meet the requirements of large-tonnage hoisting and improve safety. Stability, the effect of increasing the lifting tonnage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

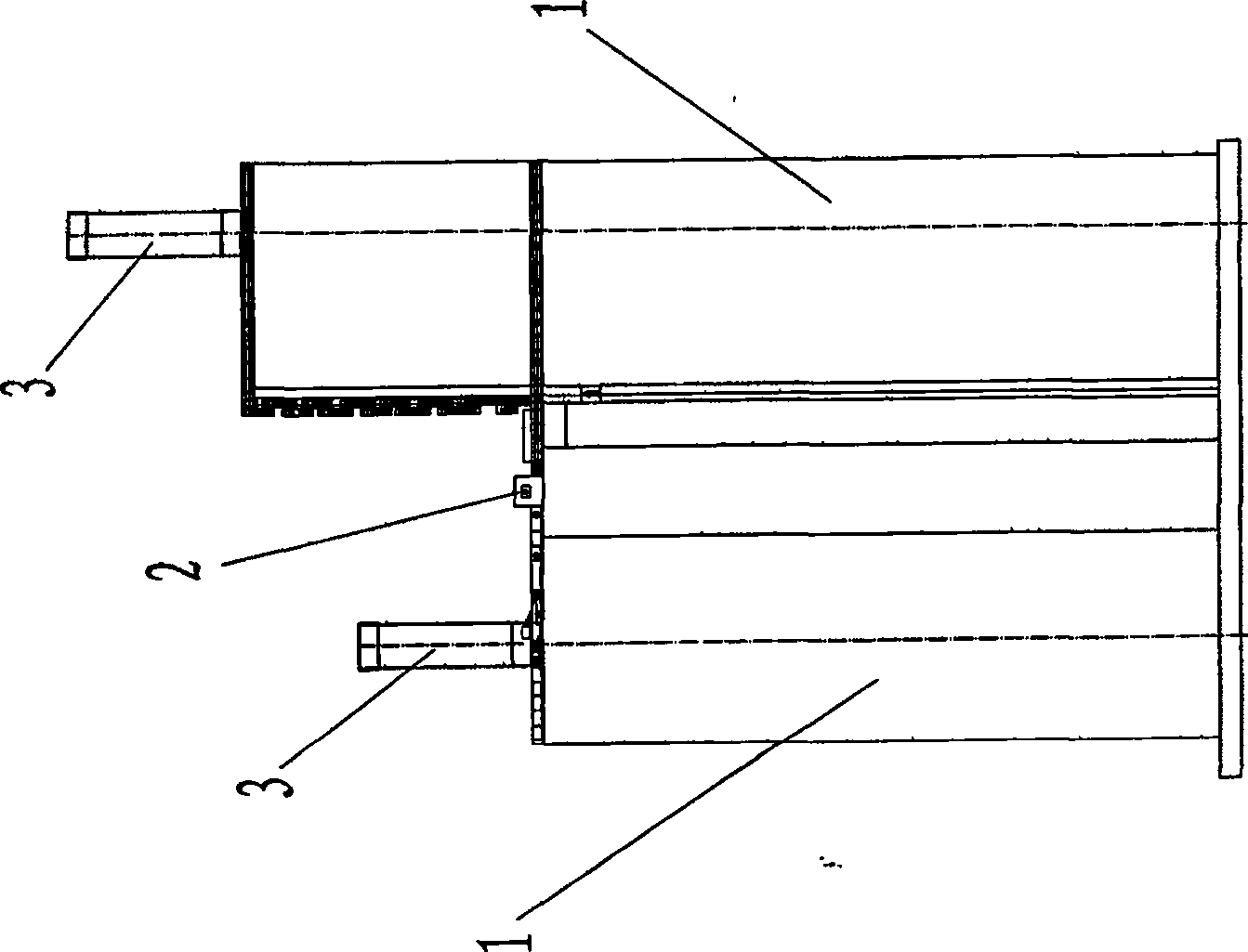

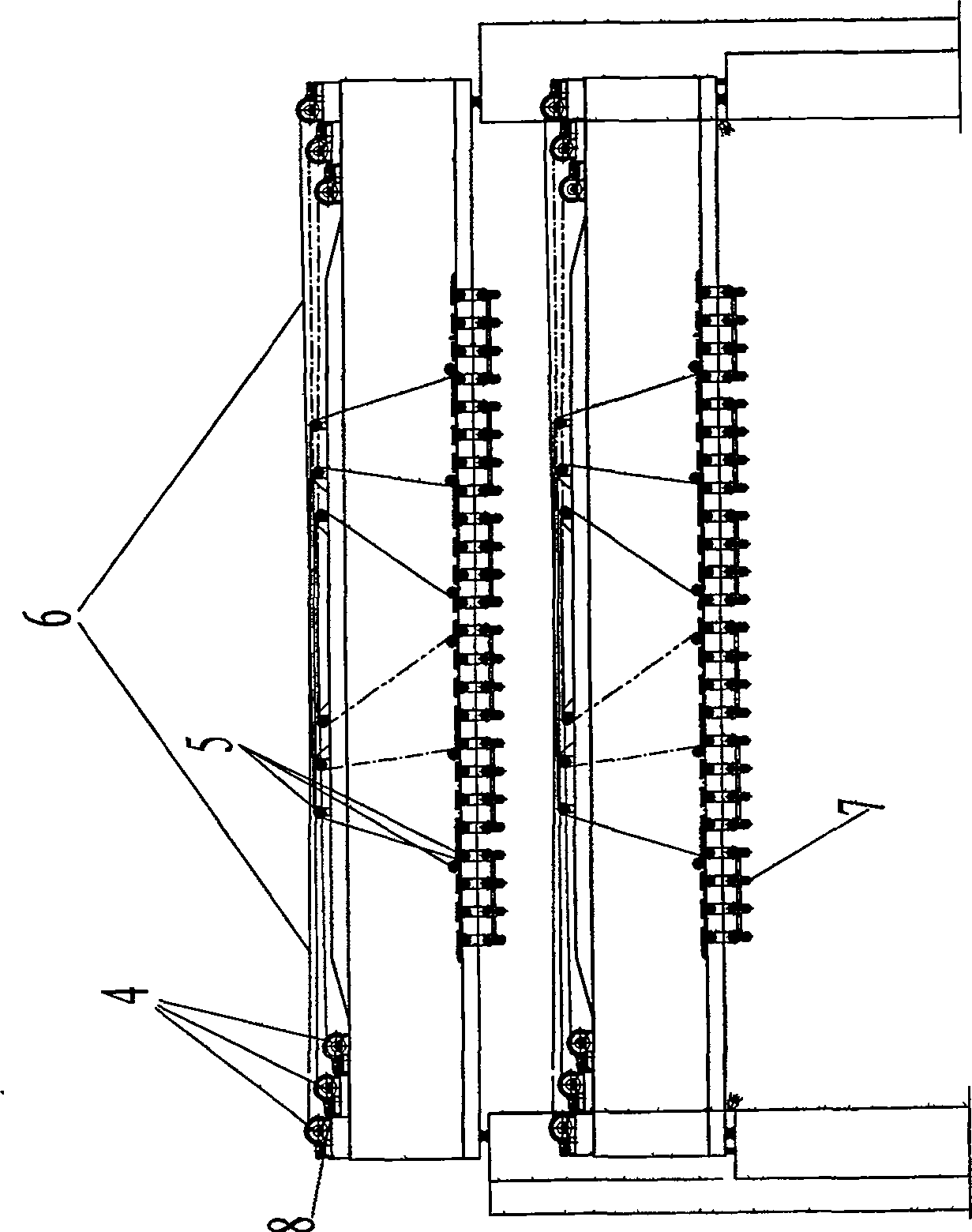

[0022] Embodiment 1, a kind of large-tonnage platform crane, refer to figure 1 , figure 2 , there are four columns 1 fixed on the ground, the opposite two columns 1 have the same height, the height of the two columns 1 near the dock door is higher than the height of the two columns 1 far away from the dock door, and the two ends of the crossbeam 3 are respectively arranged on the opposite sides. On the two tall columns 1, the cross-section of the beam 3 is box-shaped and adopts a variable-section welded structure. A set of hoisting mechanisms 8 composed of a hoist 4, a pulley block 5 and a hook 7 are provided on both sides of each beam 3. The lifting device 8. The hoisting device structure of the existing crane is adopted, and an operating room 2 is arranged between the two columns 1 on the same side, and the electrical control system controls the electrical device of the whole crane, which constitutes a structure of the present invention.

Embodiment 2

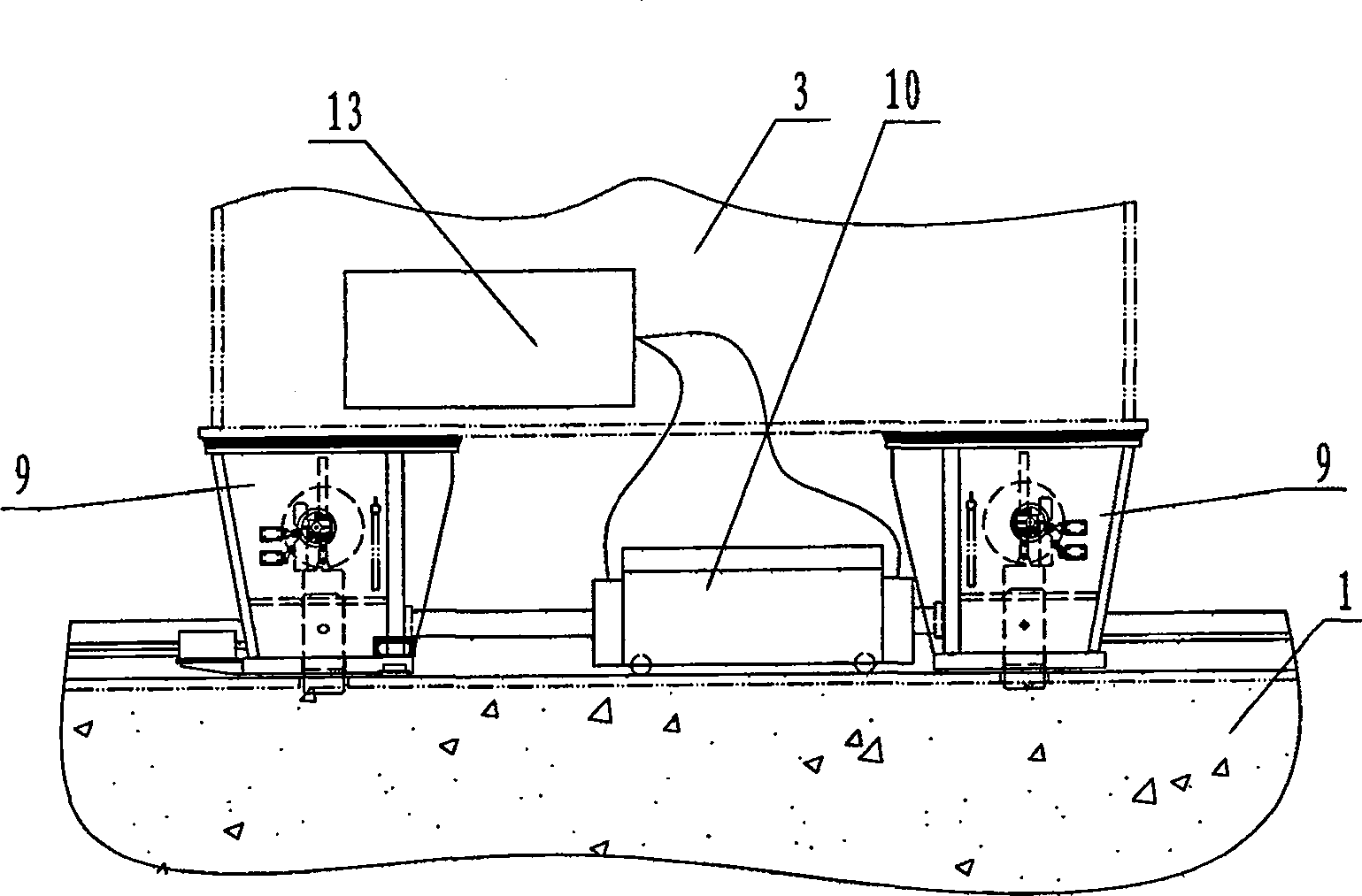

[0023] Embodiment 2, a kind of large-tonnage platform crane, refer to figure 1 , figure 2 , image 3 , Figure 4 , on the basis of Embodiment 1, a crossbeam translation device is provided at the connection between the crossbeam 3 and the column 1, and the device is fixed with sliding oil cylinder hinge supports 9 on both sides below the end of the connection between the beam 3 and the column 1, The plane where the sliding oil cylinder hinge support 9 is located is perpendicular to the axial direction of the crossbeam 3, and two sets of hydraulic cylinders 10 vertical to the axial direction of the crossbeam 3 are arranged in the middle of the sliding oil cylinder hinge support 9, and the two ends of the hydraulic cylinder 10 are respectively fixed on two sliding On the cylinder hinge support 9, a locking device 11 is provided between the two sets of hydraulic cylinders 10, and a locking track 12 parallel to it is provided between the two sets of hydraulic cylinders 10. The u...

Embodiment 3

[0024] Embodiment 3, a kind of large-tonnage platform crane, refer to figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , on the basis of Embodiment 2, a maintenance crane 17 is respectively provided at both ends of each beam, a hoist crane 18 is provided inside each beam, and anchoring is provided between each column 1 and the beam 3 on it device and windproof cable 19, the anchoring device is that both sides below the crossbeam 3 ends are respectively fixed with anchoring brackets 20, and two anchoring brackets 20 are fixed inside the screw elevator base 21 along the outside of the beam direction, and the screw elevator base 21 is provided with a spiral The anchor plate 28 is fixed by the lower pin of the screw lift 22, the screw lift 22 is connected with the outer hand wheel 23 of the anchor bracket 20, and the lifting mechanism is 3-8 winches 4, and the winches 4 are distributed along the direction of the crane beam 3 And the height is successively l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com