Injection mold

A technology for injection molds and molds, which is applied to household appliances, other household appliances, threaded products, etc., and can solve the problems of inability to achieve automatic demoulding and cumbersome demoulding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

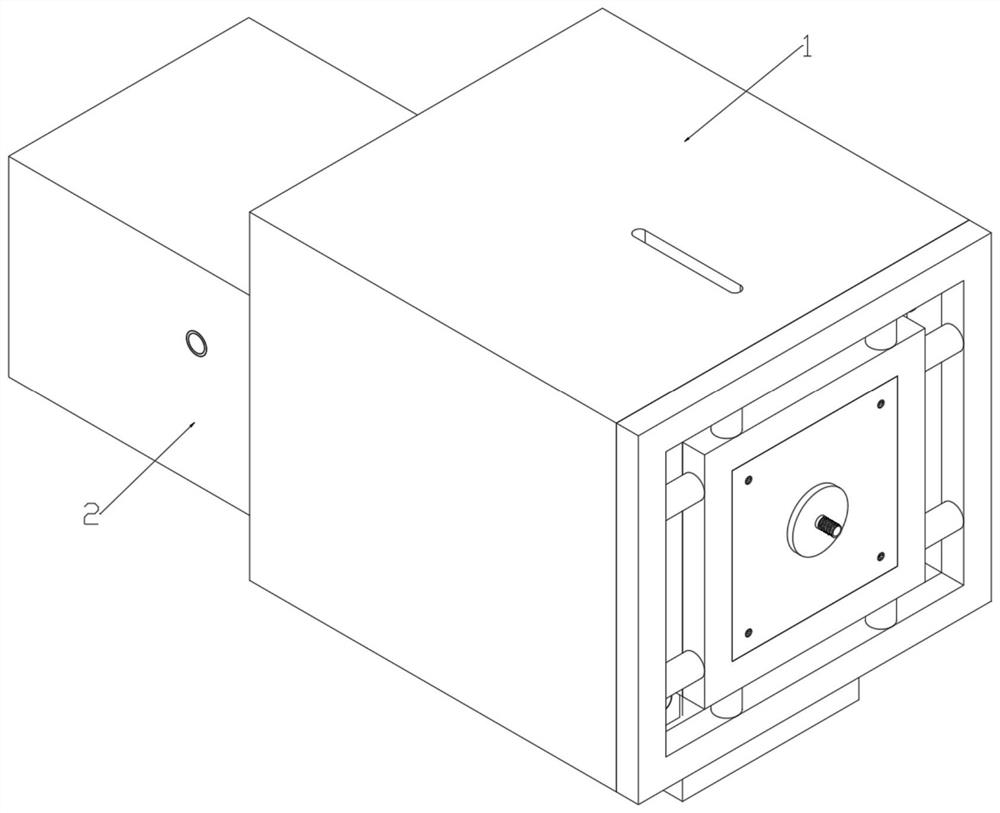

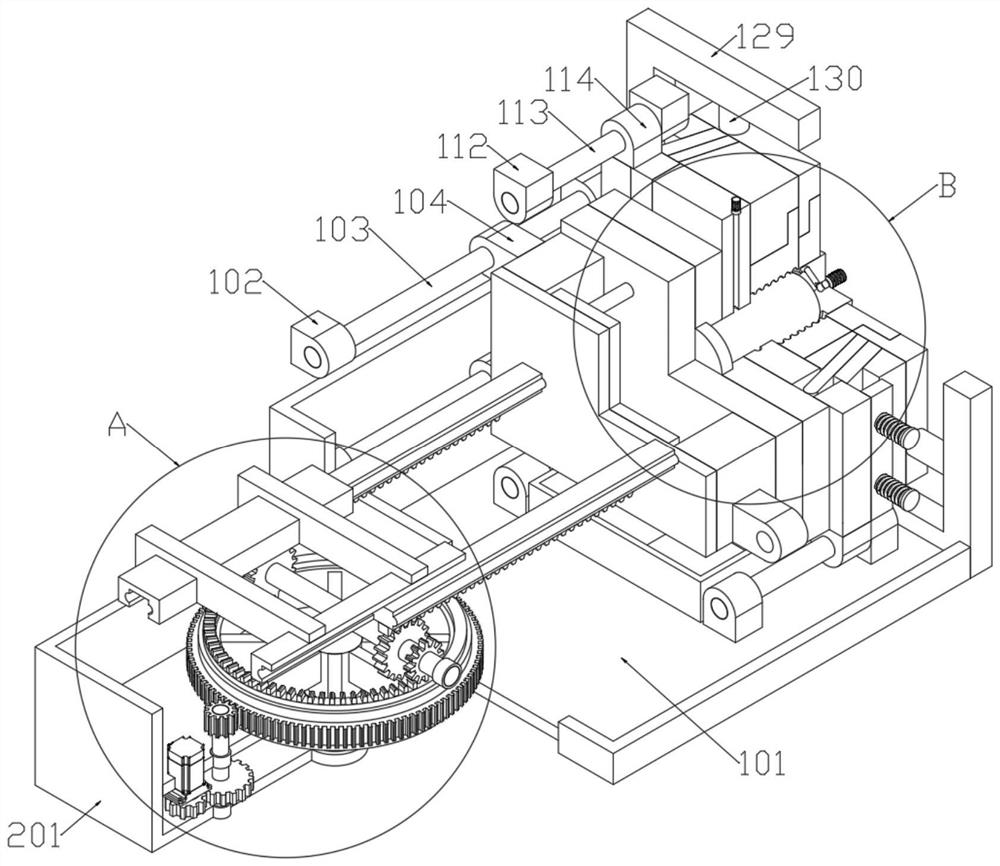

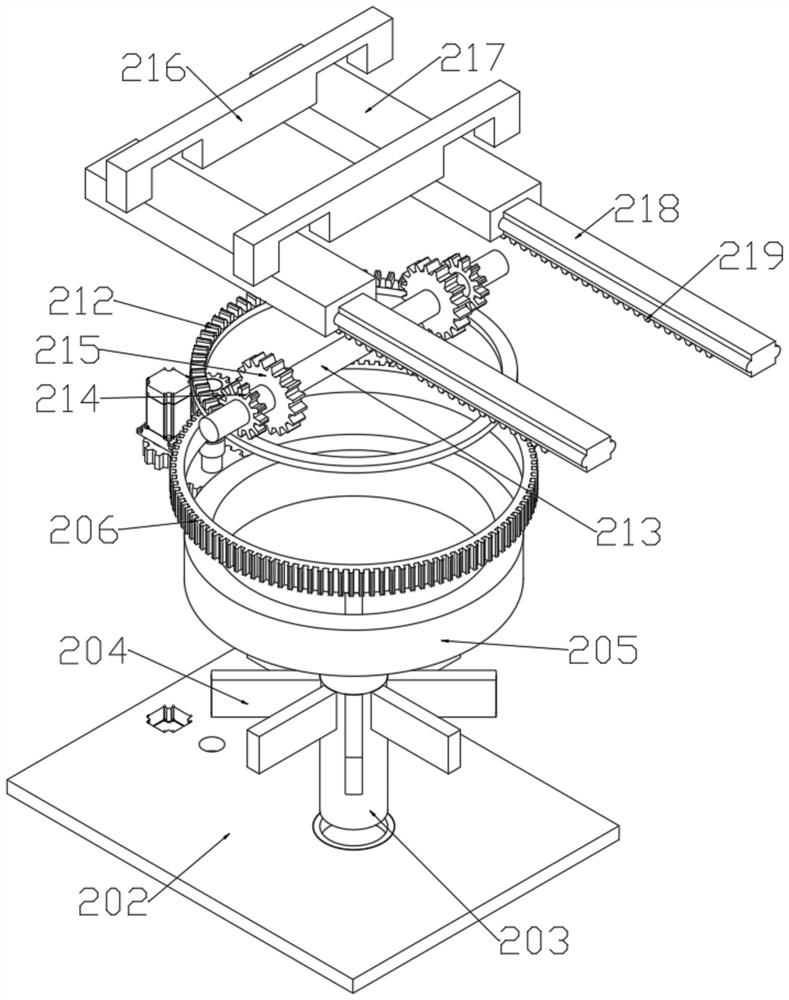

[0032] Example: such as Figure 1-9As shown, the present invention provides an injection mold, including a mold mechanism 1, and the mold mechanism 1 includes a mold box 101, and two symmetrically distributed rectangular columns 105 are installed inside the mold box 101. A first limiting plate 106 is installed on one side of the column 105, and a second fixing plate 109 is installed on the other side of the two rectangular columns 105, and the first fixing plate 109 is installed on the side away from the rectangular column 105. Plate 107, a column 110 is installed at the center of the first fixed plate 107, and two first connecting columns 115 are installed on the side of the first fixed plate 107 away from the second fixed plate 109, and the two first connecting columns 115 are installed A third fixed plate 117 is installed between the columns 115, two first fixed frames 126 are installed on the side of the third fixed plate 117 away from the second fixed plate 109, and two f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com