Open ceramic product dry pressing forming device with automatic demolding function

A technology of automatic demolding and dry pressing, which can be used in ceramic molding machines, unloading devices, manufacturing tools, etc., and can solve the problems of difficult demoulding and slow molding speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

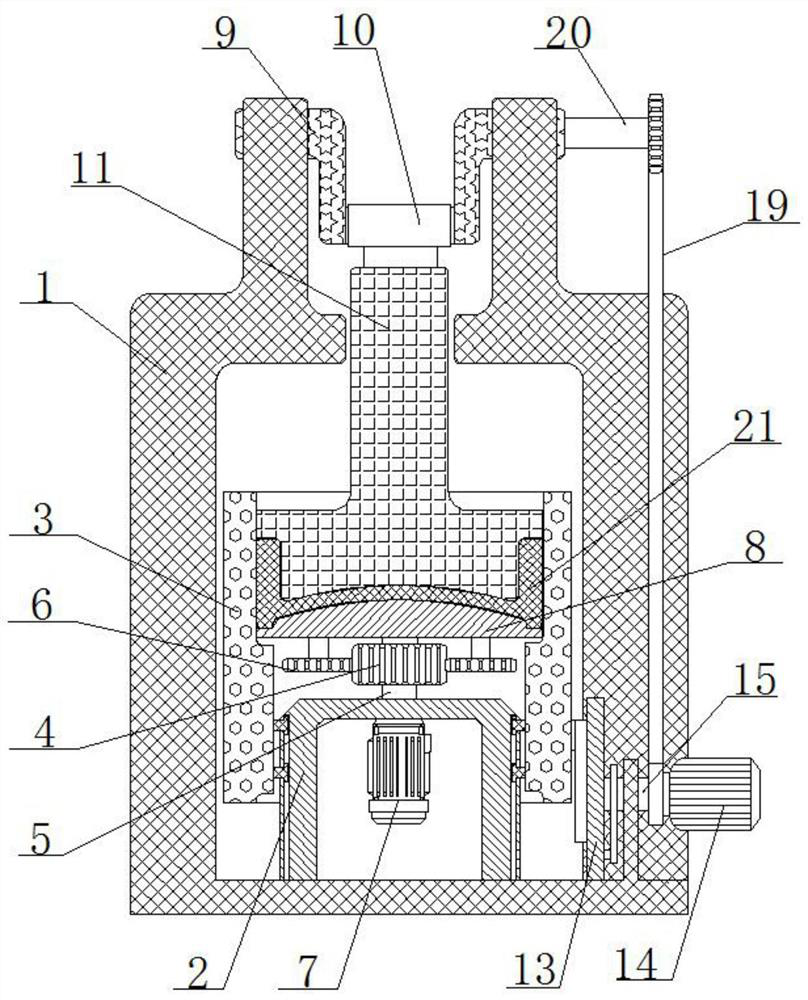

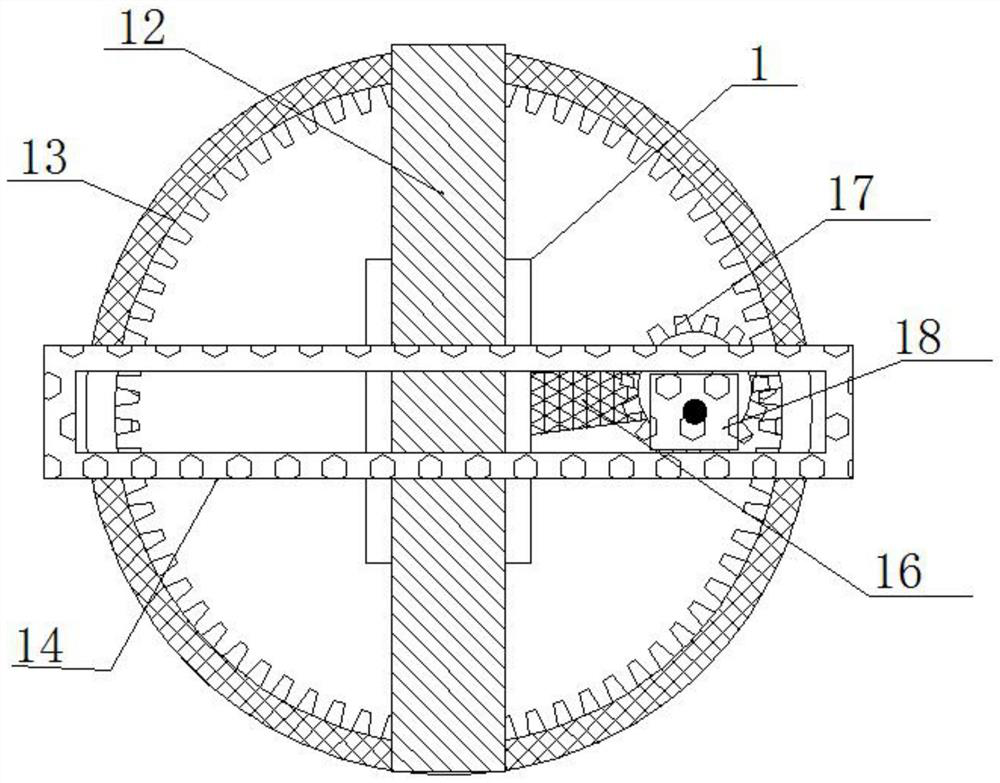

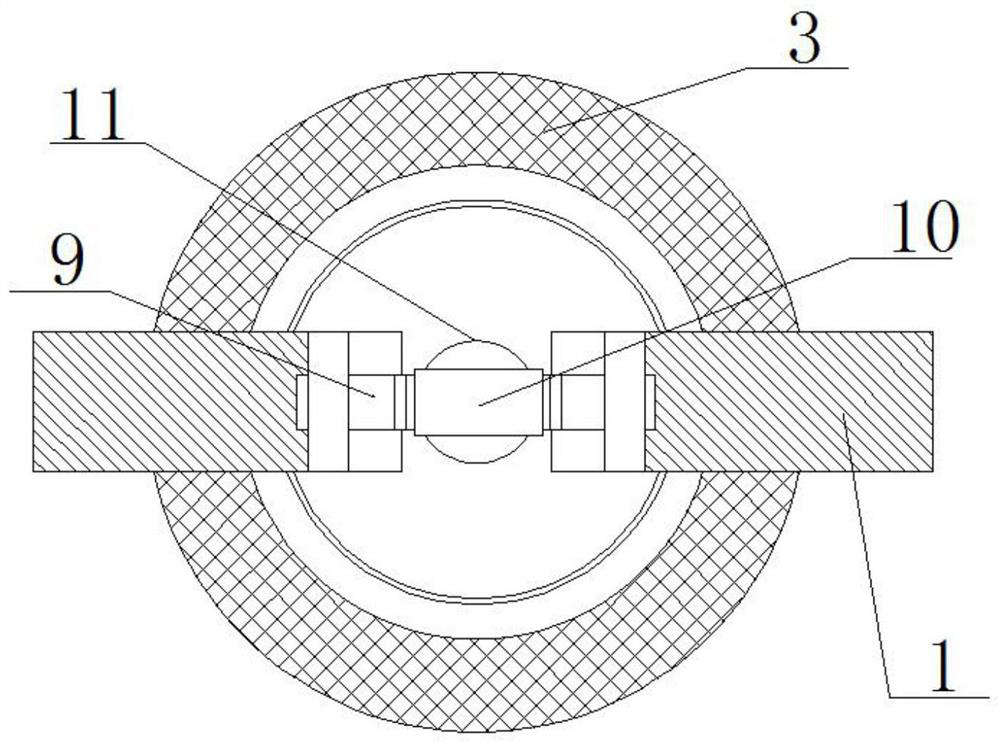

[0026] as attached figure 1 to attach Figure 4 Shown:

[0027] A dry pressing device for open ceramic products with automatic demoulding function, comprising a frame 1, a rectangular plate of the frame 1, a circular through hole adapted to the rotating crank 9 is opened on the top, and a pressing block 11 is opened on the top Adapted circular hole, the front is provided with a rectangular cavity adapted to the lifting mold 3, the inside of the frame 1 is fixedly connected with the motor bracket 2, the motor bracket 2 is an inverted U-shaped frame, and the top is opened to match the support rod 5 There are circular through holes on both sides, rectangular chute compatible with the lifting mold 3, and a threaded hole at the bottom. The outer side of the motor bracket 2 is slidingly connected with the lifting mold 3. The lifting mold 3 is cylindrical, and the inside is provided with a The lower bottom plate 8 and the pressure block 11 are adapted to the stepped circular hole, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com