Device and method for thermoforming gradient materials

A technology for hot-pressing forming and gradient materials, applied in the field of metal powder forming devices, can solve the problems of unadjustable temperature gradient and limited temperature gradient, and achieve the effects of replaceable parts, simple equipment and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the drawings and embodiments.

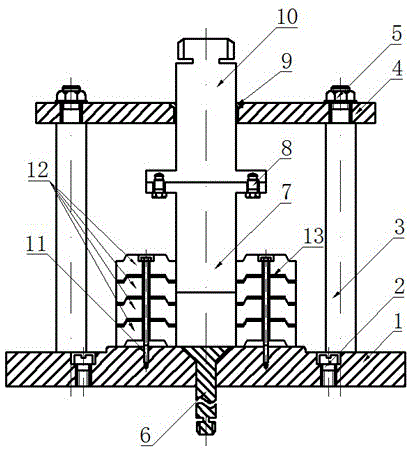

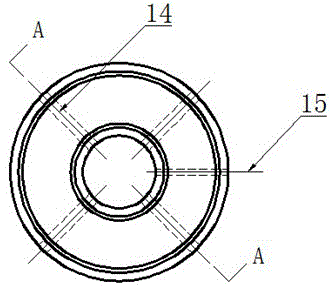

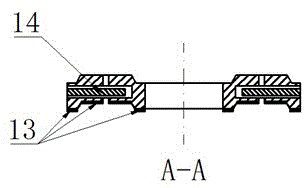

[0033] Such as figure 1 As shown, the upper mold base 4 and the lower mold base 1 of the present invention are connected by four pillars 3 with nuts 5; the lower mold base 1 is fixed to the base by screws 2; the lower mandrel 6 passes through the guide post in the upper center of the lower mold base 1. The hole and the inclined surface form a sliding fit with the lower mold base 1. The upper surface of the lower ejector rod 6 and the upper surface of the lower mold base 1 are kept on the same horizontal plane; multiple molds 12 with the same structure are installed by stacking up and down to become a gradient mold. It is fixed on the lower mold base 1 with long screws 11, and the adjacent molds 12 are separated by asbestos gaskets 13; the lower end of the upper punch 7 is coaxially installed with the center holes of the multiple molds 12 to form a sliding fit, and the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com