Patents

Literature

30 results about "Ceramic forming techniques" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ceramic forming techniques are ways of forming ceramics, which are used to make everyday tableware from teapots, to engineering ceramics such as computer parts. Pottery techniques include the potter's wheel, slipcasting, and many others.

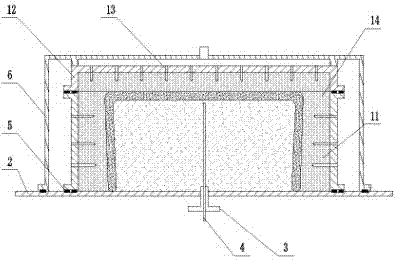

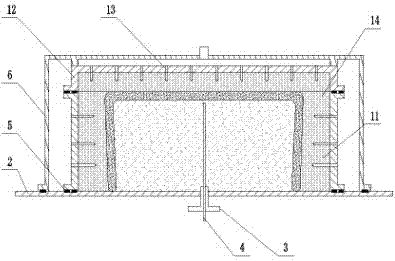

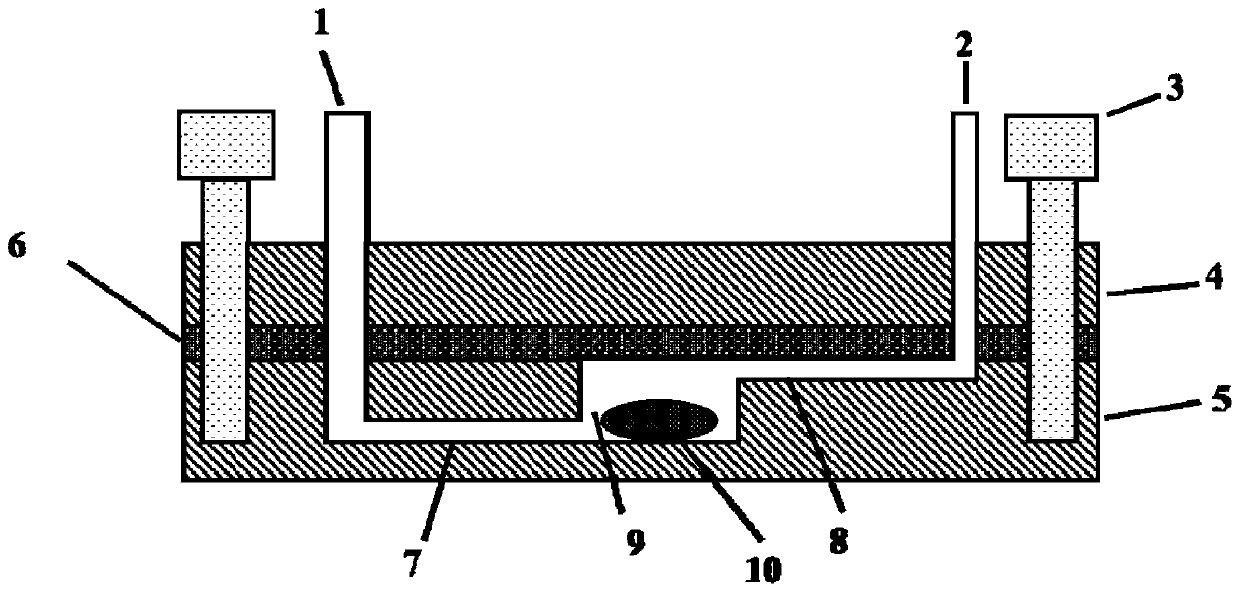

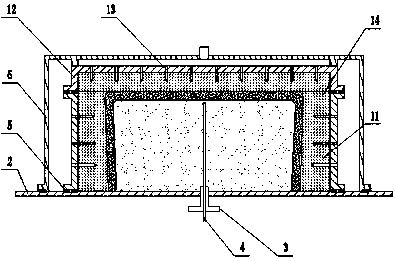

Special mold for ceramic blank high-pressure slip casting process

The invention belongs to the technical field of ceramic forming and particularly relates to a bathroom ceramic blank forming mold, which comprises an outer mold and a support plate, wherein the support plate seals the outer mold. The bathroom ceramic blank forming mold is characterized in that the outer mold comprises a water-absorption ventilation K gypsum mold and a steel sleeve, the steel sleeve is arranged on the outer wall of the K gypsum mold, ventilation holes are arranged on the steel sleeve, and a slip casting opening and an air injection opening are arranged on the support plate. When a special mold for the ceramic blank high-pressure slip casting process disclosed by the invention is adopted, the intensity is high, the high-pressure damage is avoided, and in addition, water penetration and ventilation can be realized.

Owner:重庆国之四维卫浴有限公司

High pressure grouting forming process for ceramic billet

ActiveCN102528898ANot fragileEasy to separateCeramic shaping apparatusSlurryCeramic forming techniques

The invention belongs to the technical field of ceramic forming, in particular relates to a forming process for a bathroom ceramic billet, which comprises the steps: (1) allocating forming materials according to ratio and mixing the forming materials into even slurry; (2) pressing the slurry into a high strength permeable mold, enabling the pressure of the slurry in the permeable mold to be kept at 0.3-1.6MPa for 0.5-5minutes, and enabling the slurry to crust and form the ceramic billet; (3) discharging the slurry left in the high strength permeable mold; (4) blowing compressed air into the high strength permeable mold, and keeping the pressure of the compressed air in the high strength mold at 0.1-0.25MPa for 0.1-1minute; (5) enabling the inside and the outside of the ceramic billet to form pressure difference of 100-1000Pa by increasing the outside pressure of the high strength permeable mold, keeping the pressure difference at no less than 0.1 second, and enabling the ceramic billet to be separated from the high strength permeable mold; and (6) separating the high strength permeable mold to obtain the ceramic billet. By means of the high pressure grouting forming process for the ceramic billet of the technical scheme, required number of the mold is small, and manufacture efficiency and compact evenness of the billet are high.

Owner:重庆国之四维卫浴有限公司

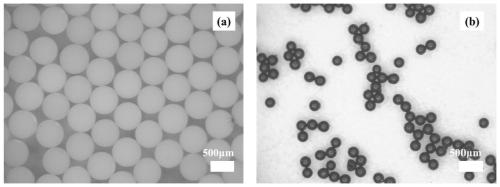

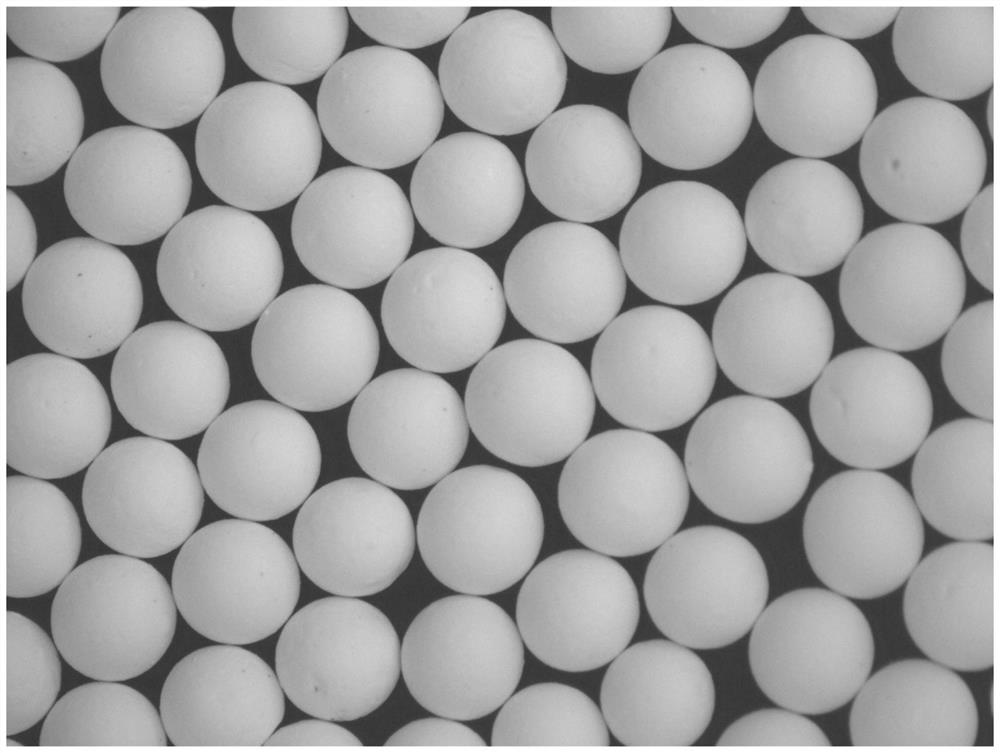

Preparation method of ceramic micro-bead grinding medium

InactiveCN107266025APerformance is not affectedWith strengthOther chemical processesClaywaresLoss rateCeramic molding

The invention relates to a preparation method of a ceramic microbead grinding medium, belonging to the technical field of ceramic molding. The present invention firstly uses kaolin, silicon carbide, lime clay etc. as raw materials, and ball mills after mixing to obtain a mixed powder; then mixes the mixed powder and water to obtain a slurry; adds egg white and sucrose respectively to the slurry, After mixing, stir to obtain a foamy slurry; ballize the foamy slurry and fire to obtain hollow ceramic microspheres, and grind the hollow ceramic microspheres to obtain hollow microspheres with a rough surface; then use Fe, Mn, Mo, etc. as The raw materials are heated and melted to obtain a mixed metal liquid, the hollow microspheres with rough surfaces are soaked in the mixed metal liquid, taken out, naturally cooled to room temperature, dried and polished. The ceramic microbead grinding medium prepared by the invention has high hardness, low wear resistance rate and good wear resistance.

Owner:周荣

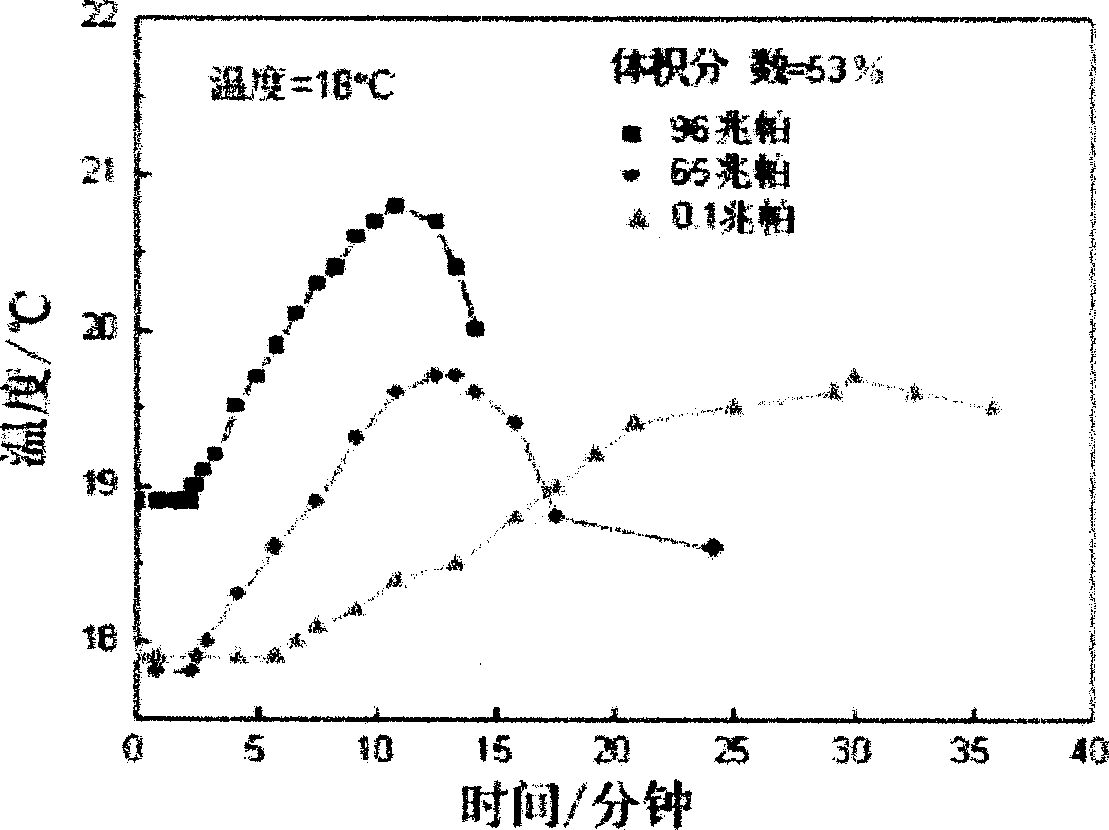

Novel vacuum degassing method for gelcasting ceramic slurry

The present invention discloses vacuum bubble-eliminating method for injected ceramic slurry via adding polymerization retarder to ensure no curing during vacuum pumping, and belongs to the field of ceramic forming technology. Into slurry, initiator, catalyst and polymerization retarder comprising phenothiazine and catechol are added through stirring; and the slurry is then pumped to eliminate bubble for 10-15 min to obtain slurry with excellent flowability and no bubble for injection directly. Adding polymerization retarder in certain amount can delay the cure of the slurry to ensure vacuum deairing effect without affecting the normal curing of the slurry in subsequent step.

Owner:TSINGHUA UNIV

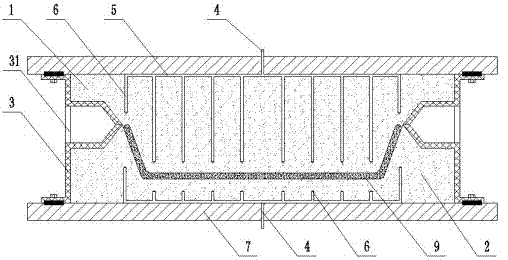

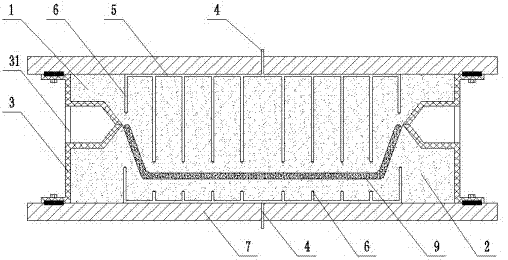

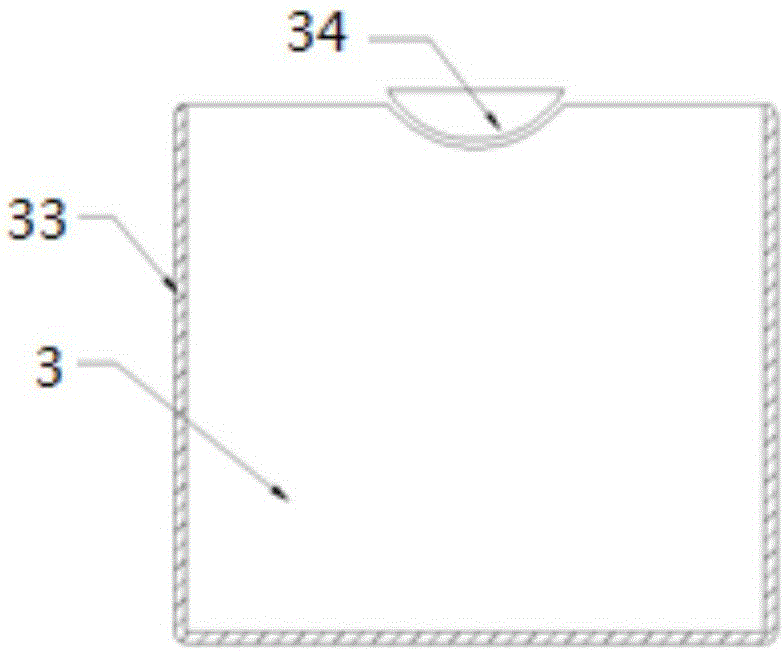

Mold special for direct-pressing forming of bathroom ceramic blank

InactiveCN102398301AReduce stickingImprove water absorptionMouldsCeramic forming techniquesMold removal

The invention belongs to the technical field of ceramic forming and in particular relates to a forming mold of a bathroom ceramic blank. The forming mold comprises a male die and a female die, which are matched with each other. The forming mold is characterized in that: the male die and the female die consist of water-absorbable and air-permeable K gypsum; steel mold sleeves are arranged on side walls of the male die and the female die and restrain the deformation of the side walls; and air inlets which are communicated with compressed air are arranged on the steel mold sleeves. By adoption of the technical scheme of the invention, the mold for direct-pressing forming of the bathroom ceramic blank is high in intensity, water-absorbable and air-permeable, and facilitates de-molding of the blank.

Owner:CHONGQING SWELL SANITARY WARE GRP

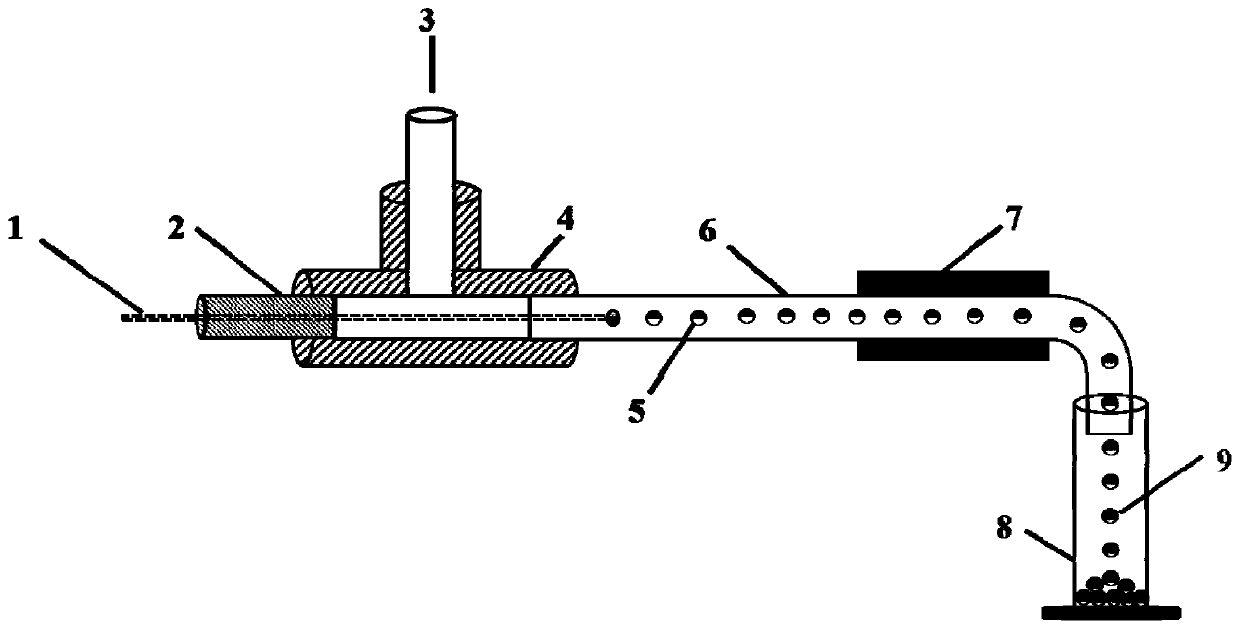

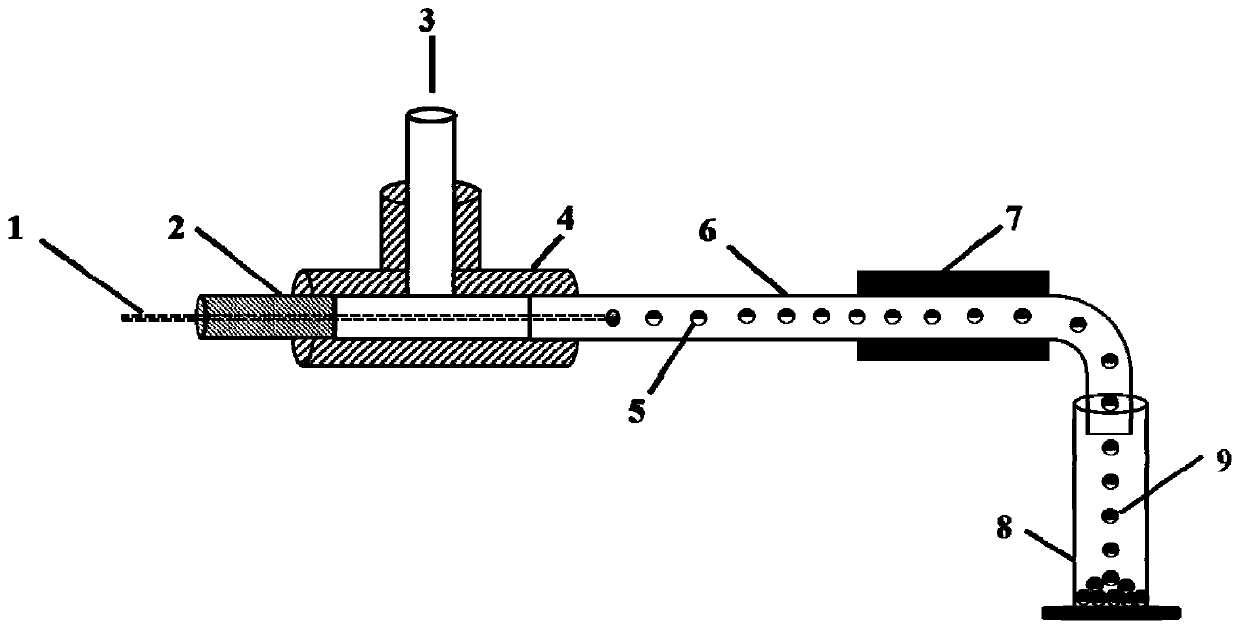

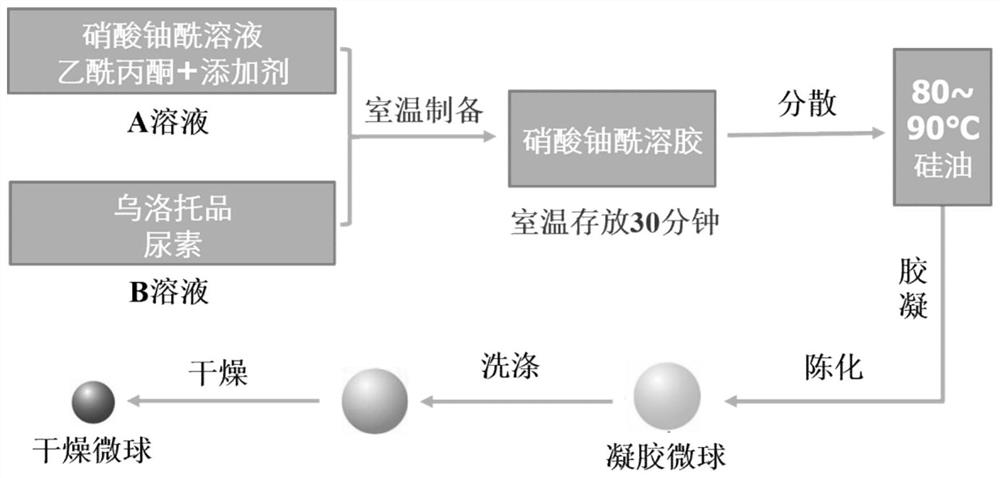

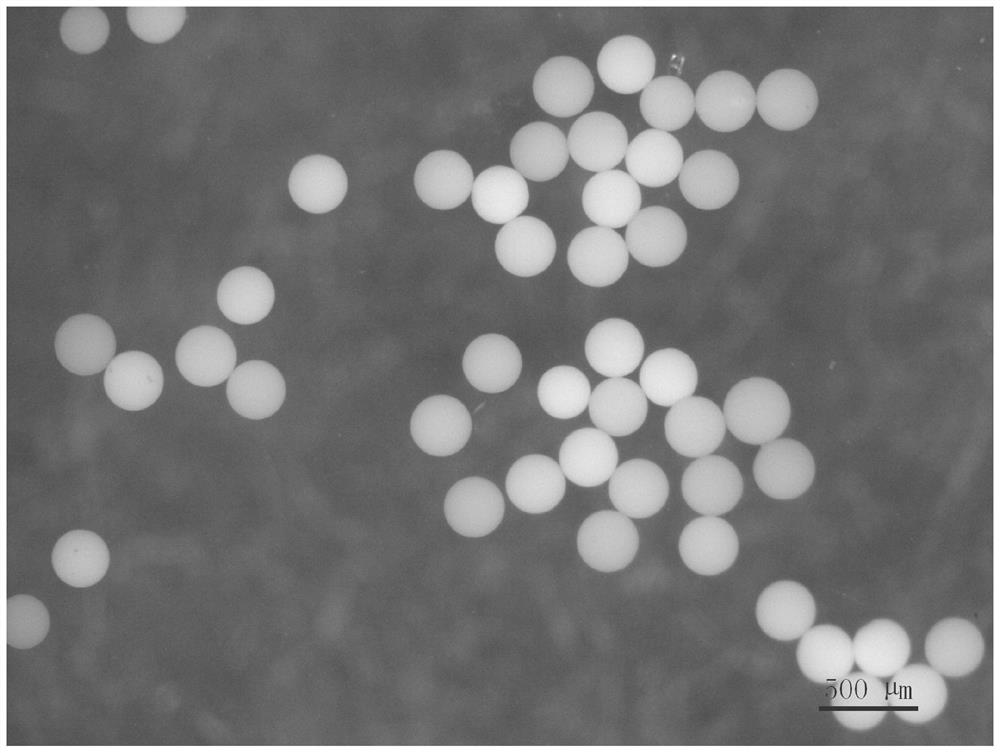

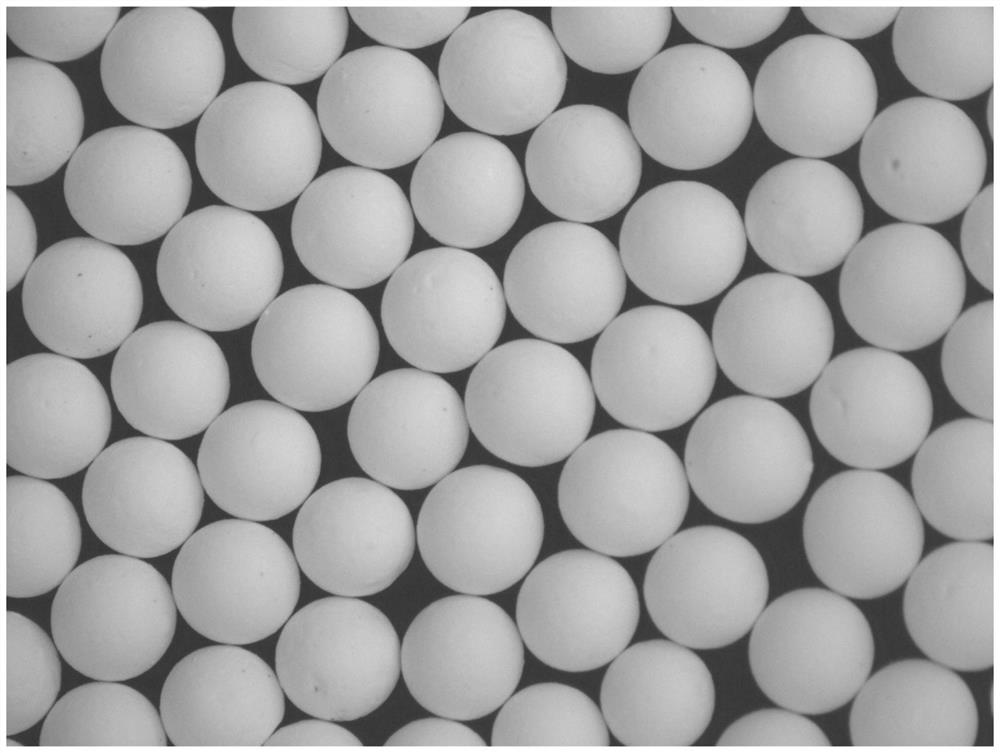

Method for preparing uranium dioxide microspheres at normal temperature

ActiveCN111039326AOvercomes the disadvantage of needing to freezeLow thermal conductivityUranium dioxideUranium oxideHexamethylenetetramine

The invention relates to a method for preparing uranium dioxide microspheres at normal temperature, and belongs to the technical field of ceramic forming. According to the method, components in an internal gel solution are divided into a uranyl nitrate solution (ADUN) stable at normal temperature and a mixed solution (HMUR) of urea and hexamethylenetetramine; the two solutions are rapidly mixed inan automatic mixing device to form an unstable uranium glue solution; the mixed uranium glue solution rapidly enters silicone oil, and is shear into liquid drops with uniform sizes by the silicone oil; the liquid drops and the silicone oil are cured into gel microspheres by a microwave heating device; and the gel microspheres are washed, dried and sintered to obtain monodisperse UO2 sintered microspheres with uniform sizes and good sphericity. According to the invention, microfluidic control is adopted in the whole process of the method, so that the UO2 microspheres are prepared at normal temperature through an internal gel method without human interference, and the automation degree is high.

Owner:TSINGHUA UNIV

Vertical compression forming process for ceramic blanks for bathrooms

InactiveCN102441935AReduce moisture contentLow input costCeramic extrusion diesCeramic forming techniquesForming processes

The invention belongs to the technical field of ceramic forming, and particularly relates to forming process for ceramic blanks for bathrooms. The forming process comprises steps that 1, forming materials are prepared according to proportion and mixed uniformly, 2, forming mud of a blank is refined and uniformly mixed, and moisture content of the mud is controlled below 30%, 3, forming mud in corresponding weight is taken according to the weight of the formed blank, 4, the forming mud is placed in a forming mold, and the mold is squeezed so that the blank is formed, and 5, by the aid of the forming mold, air is blown into a combined part of the forming mold and the blank, so that the blank is separated from the forming mold and is produced. The vertical compression forming process for ceramic blanks for bathroom is fast in forming speed, high in manufacturing efficiency, low in mold cost and small in occupied area, and the blank is compact sufficiently.

Owner:CHONGQING SWELL SANITARY WARE GRP

Liquid phase pretreatment method for gelcasting ceramic blank before binder burning out

The present invention belongs to the field of ceramic forming technology, and is the new liquid phase pre-treatment method of degrading organic matter in biscuit to prevent cracking during eliminating glue. The ceramic biscuit after gel injection molding is liquid phase pre-treated inside water solution o ammonium persulfate or potassium persulfate before eliminating glue. Under the action of peroxide, the polymer inside the ceramic biscuit is chain breaking degraded, the netted macro molecule becomes small molecule and internal stress in the biscuit is released. The biscuit thus treated will not crack and will have no fault during overheat defatting and glue eliminating. The present invention is simple in technological process, low in cost and suitable for industrial production.

Owner:TSINGHUA UNIV

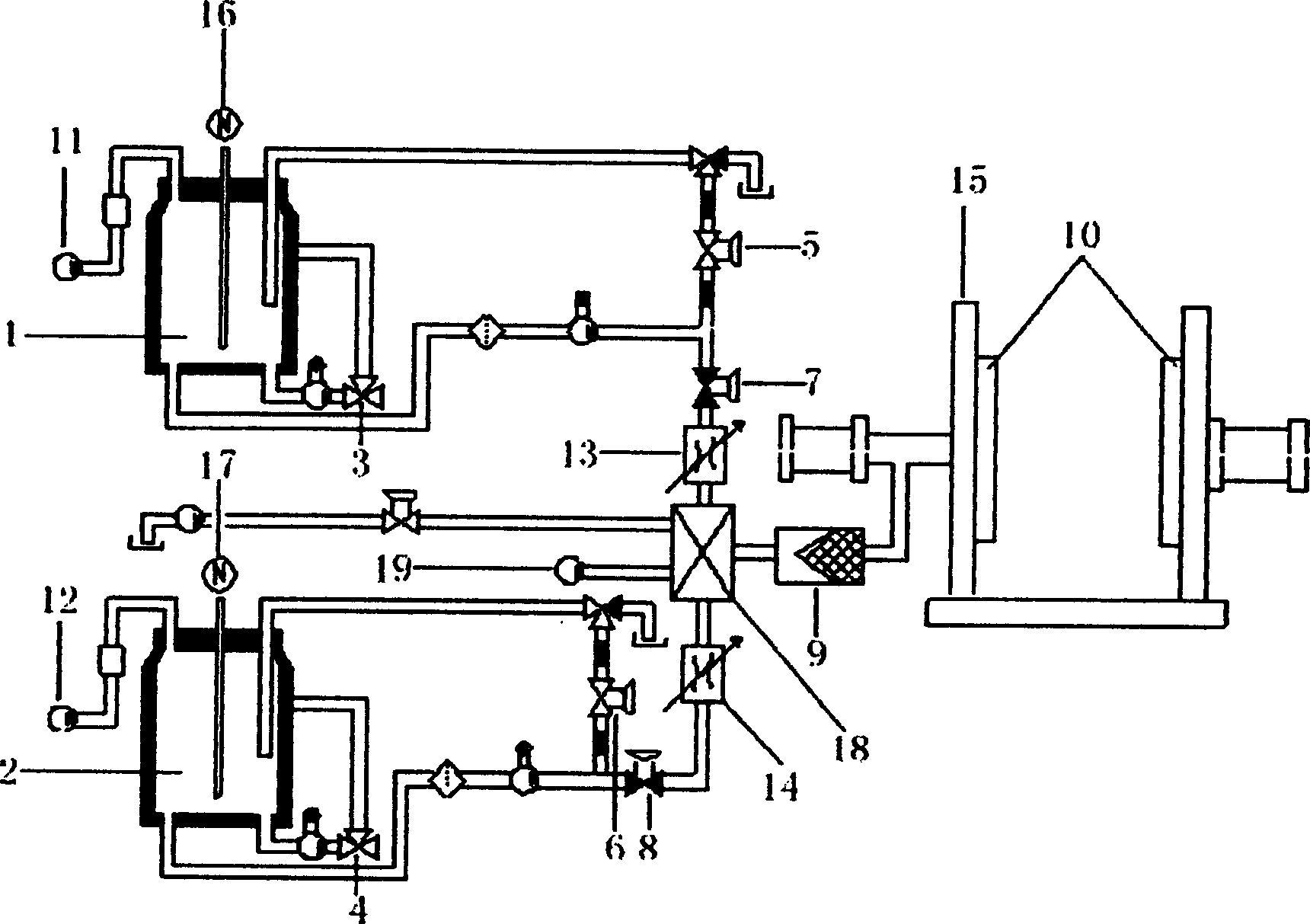

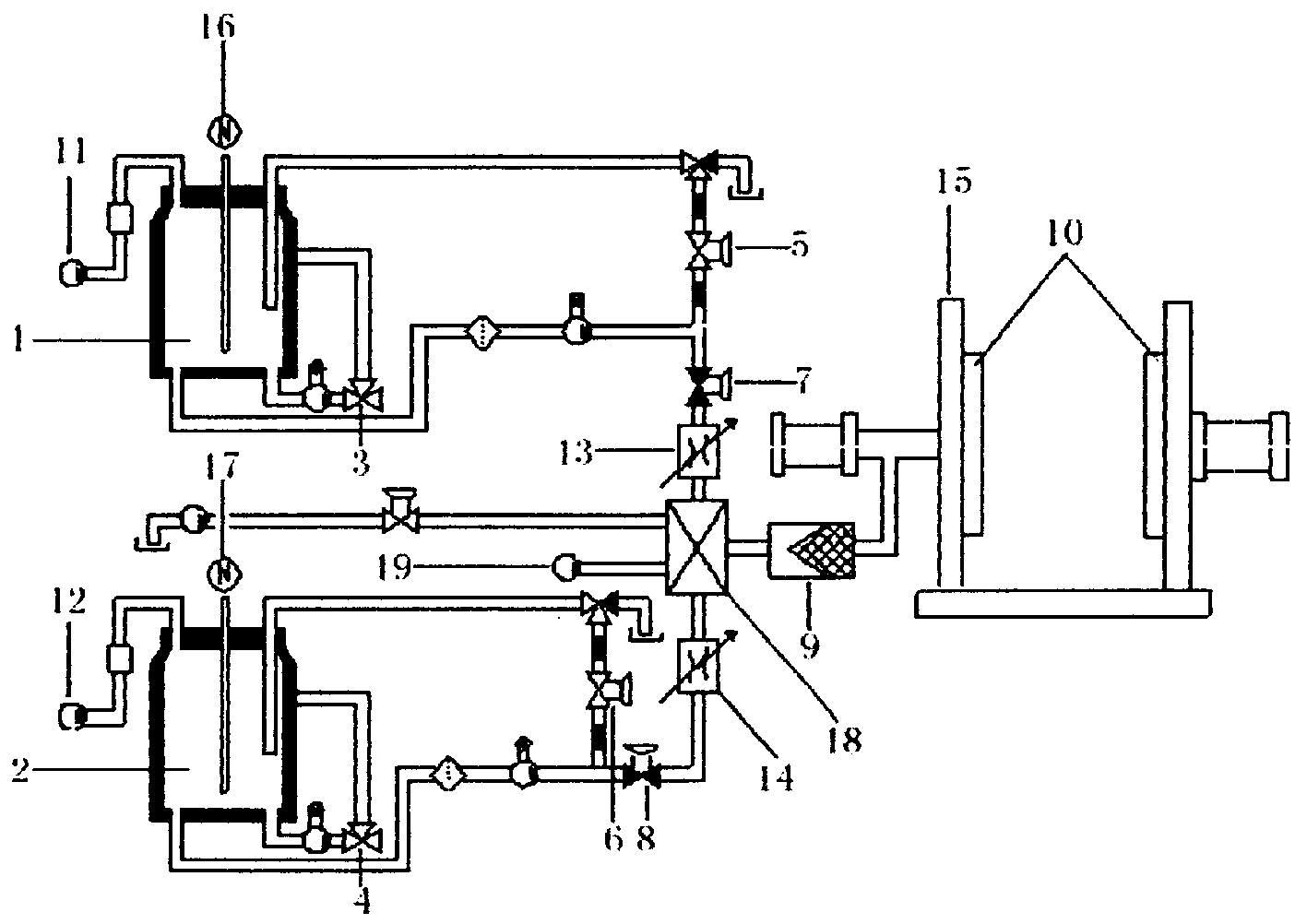

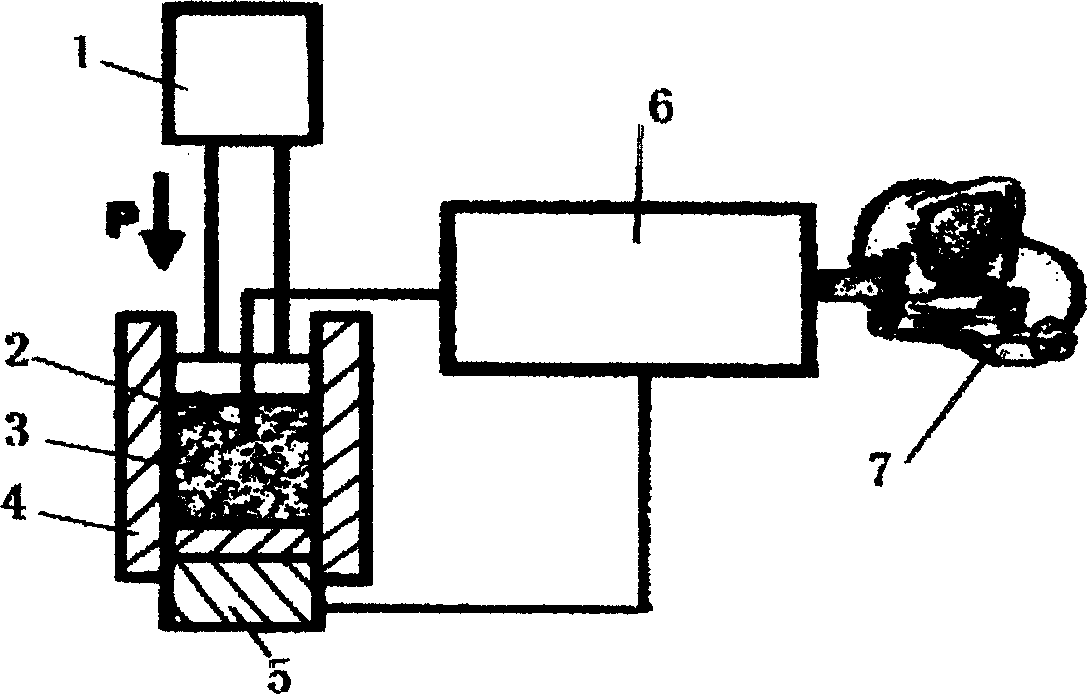

Cermic Sizing material fast and controllable solidfying colloied state shaping method and device

InactiveCN1246255CQuality improvementShort curing timeCeramic shaping apparatusCement mixing apparatusSlurryHigh pressure

A process and apparatus for controllable fast solidification of shaped colloidal ceramics are disclosed. Said apparatus is composed of two vacuum storage tanks for different ceramic slurries, mixing system, diaphragm-type metering unit, high-pressure opposite jetting mixer, static mier, and mould. Said process includes stirring two ceramics slurries in vacuum state respectively, fostly injecting them in static mixer, high-pressure opposite jetting mixing, injecting in vacuum mould, and fast reaction and solidification. Its advantages are uniform solidifying and no internal stress.

Owner:TSINGHUA UNIV

Device for preparing large-size monodisperse uranium dioxide microspheres

InactiveCN111167387ALittle effect of gravityGood sphericityNuclear energy generationGel preparationUranium oxideMicrosphere

The invention relates to a device for preparing large-size monodisperse uranium dioxide microspheres, and belongs to the technical field of ceramic forming. The preparation device comprises a dispersion phase fluid inlet pipe, a continuous phase fluid inlet pipe, an outlet pipe, a T-shaped tee joint and a water bath tank;adispersionphase fluid uranium glue solution and acontinuous phase fluid silicone oil are respectivelyintroduced into the T-shaped tee joint through the dispersionphase fluid inlet pipe and the continuous phase fluid inlet pipe, and the silicone oil is adopted for shearing theuranium glue solution at the tail ends of capillary tubes, so that the uranium glue solution is crushed into liquid drops with uniform sizes one by one. The size of the outlet pipe in the T-shaped tee joint can be flexibly replaced, and therefore large-size liquid drops can be flexibly prepared by adjusting the flow of uranium glue solution and silicone oil and the size of the outlet pipe. The large liquid drops may be insufficiently cured, the outlet pipe can be placed in a temperature-controllable water bath to be pre-cured, and energy is provided for curing of the large liquid drops, so that the large-size gel microspheres with good sphericity and uniform size are obtained.

Owner:TSINGHUA UNIV

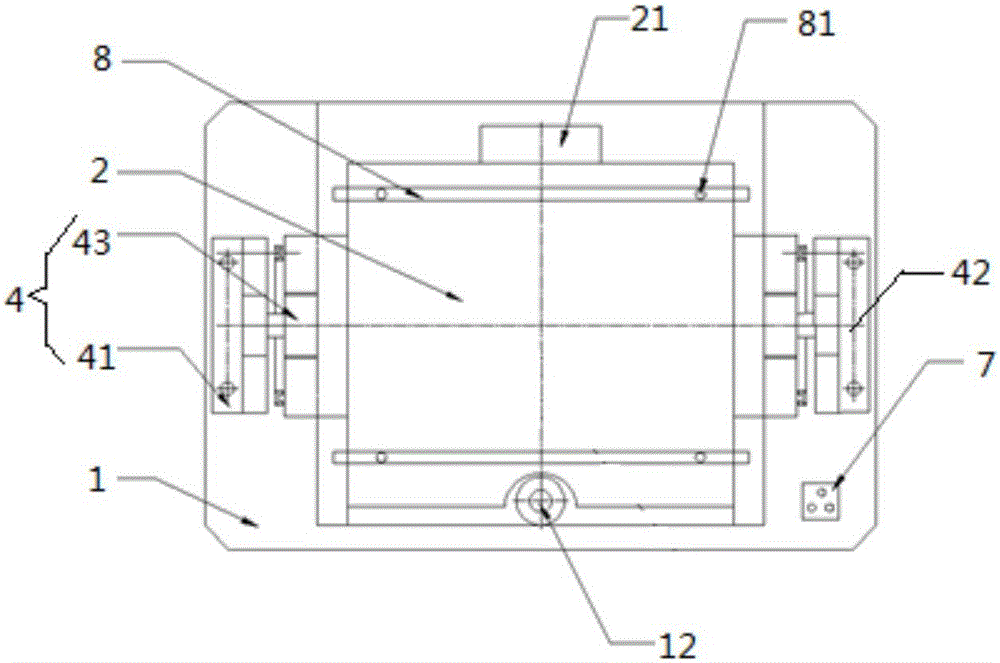

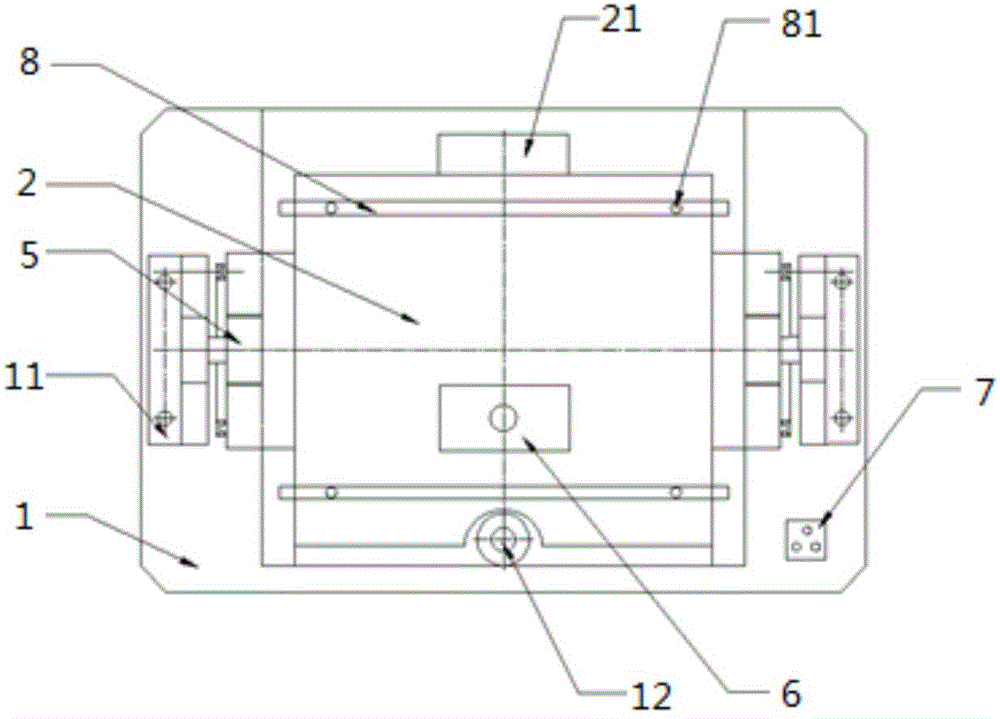

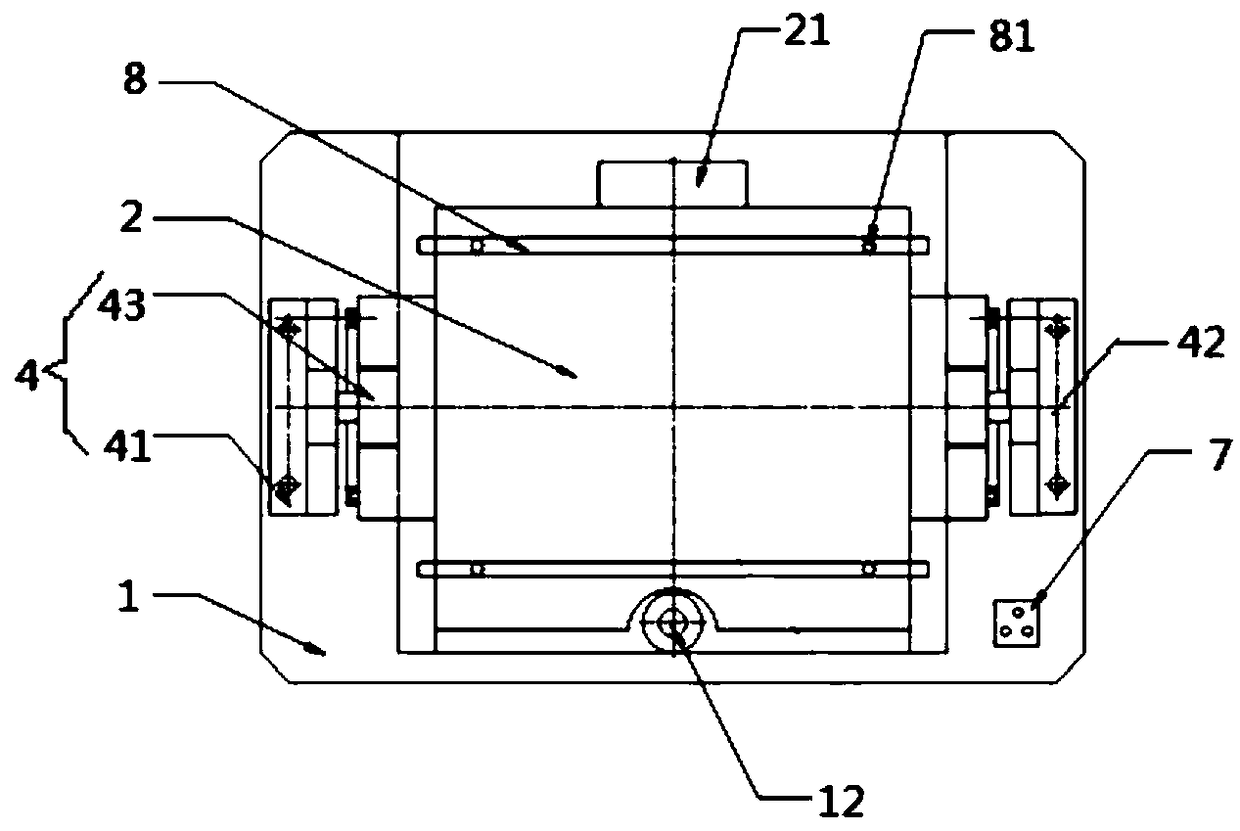

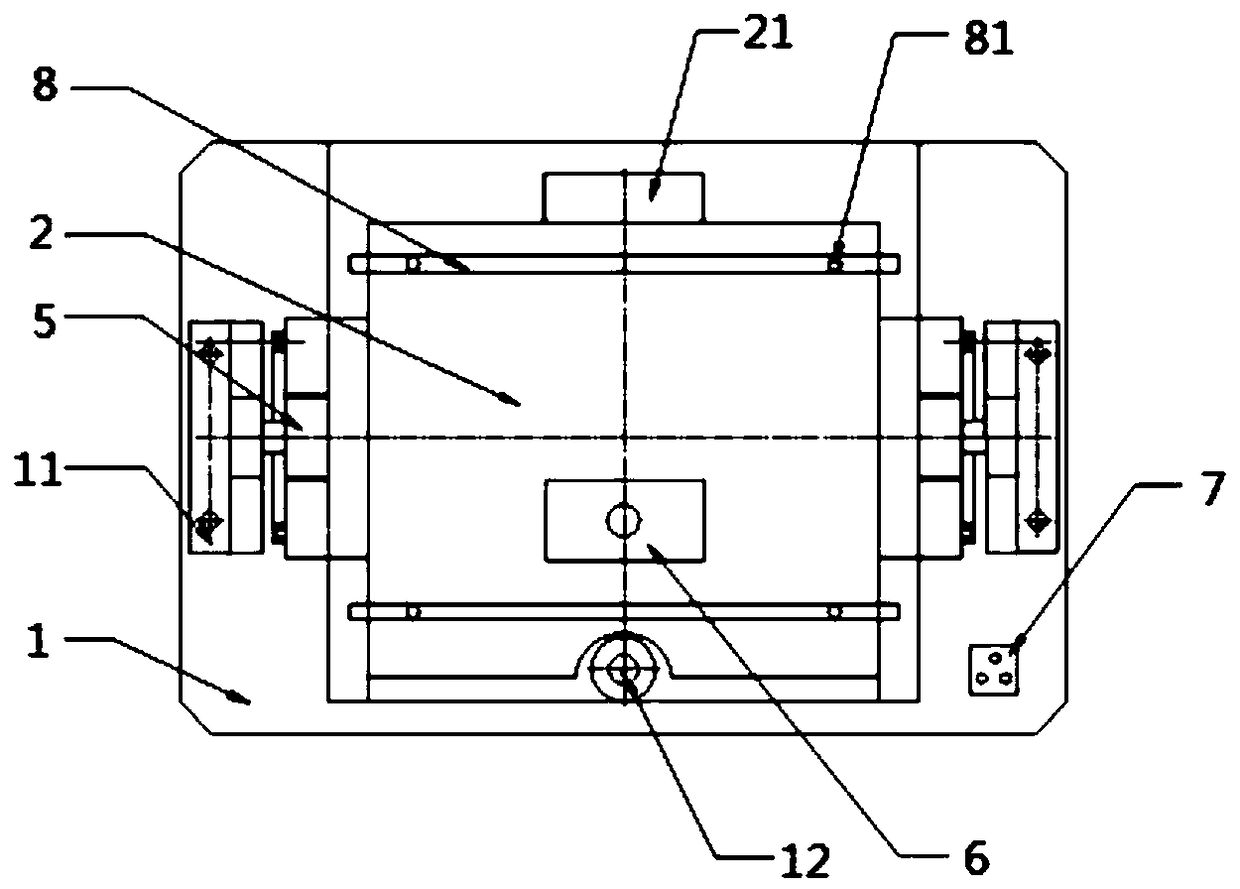

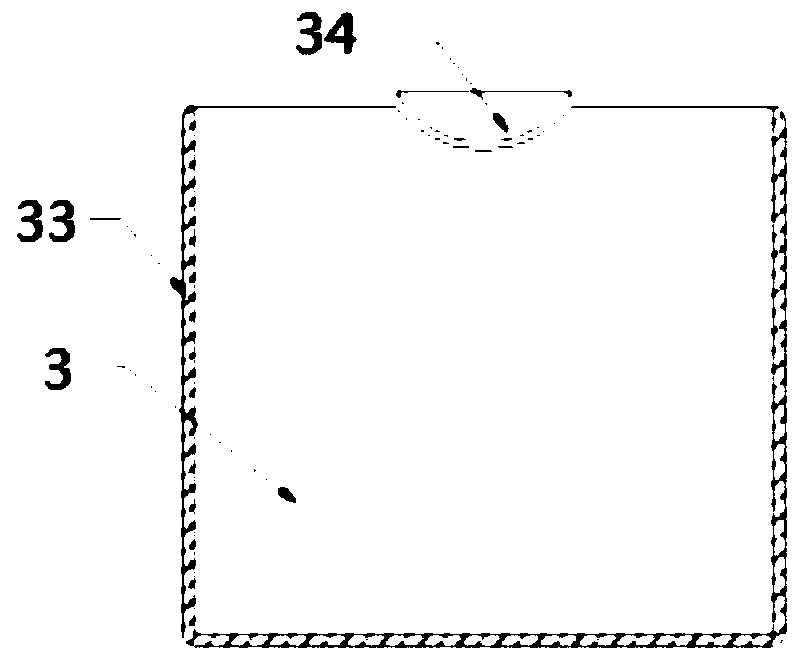

Sheet-shaped-ceramic forming device and use method thereof

ActiveCN106182337AUniform bulk densityEnsure consistent qualityMould auxillary partsAuxillary shaping apparatusAcute angleSlurry

The invention discloses a sheet-shaped-ceramic forming device and a use method of the sheet-shaped-ceramic forming device and relates to the technical field of forming of sheet-shaped ceramics. The sheet-shaped-ceramic forming device and the use method of the sheet-shaped-ceramic forming device achieve the effects of guaranteeing the quality consistency of products and improving production efficiency. According to the technical scheme, the sheet-shaped-ceramic forming device comprises a base, a platform and a forming mold. The base is provided with a first end face. The platform is arranged on the base in an inclined manner. The platform is provided with a second end face and a third end face opposite to the second end face. The second end face is opposite to the first end face. An included angle between the third end face and the first end face is an acute angle. The forming mold is of a platy structure and is laid on the third end face, and ceramic slurry is poured into the forming mold in an inclined manner.

Owner:CHINA BUILDING MATERIALS ACAD

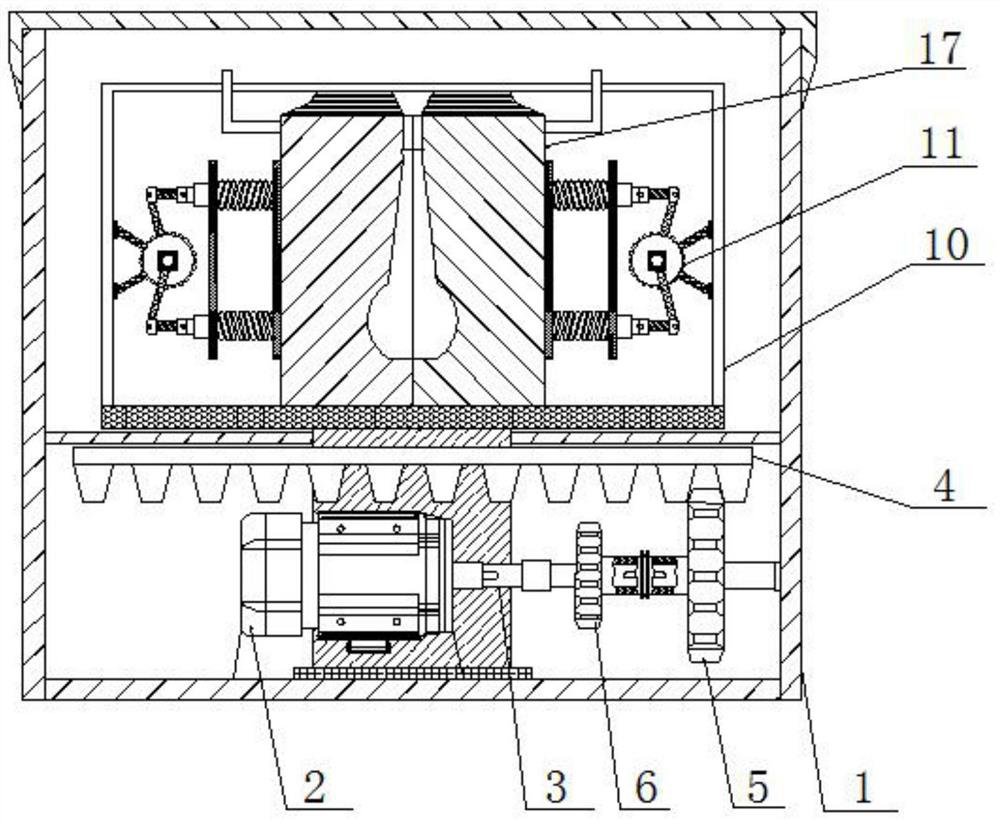

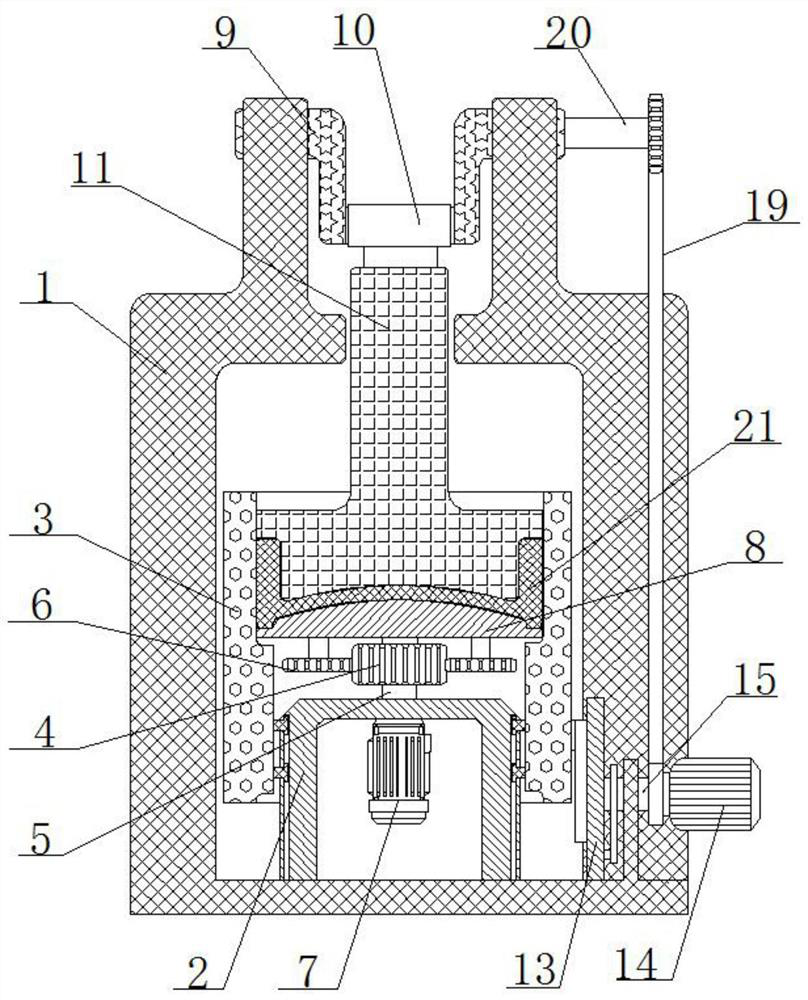

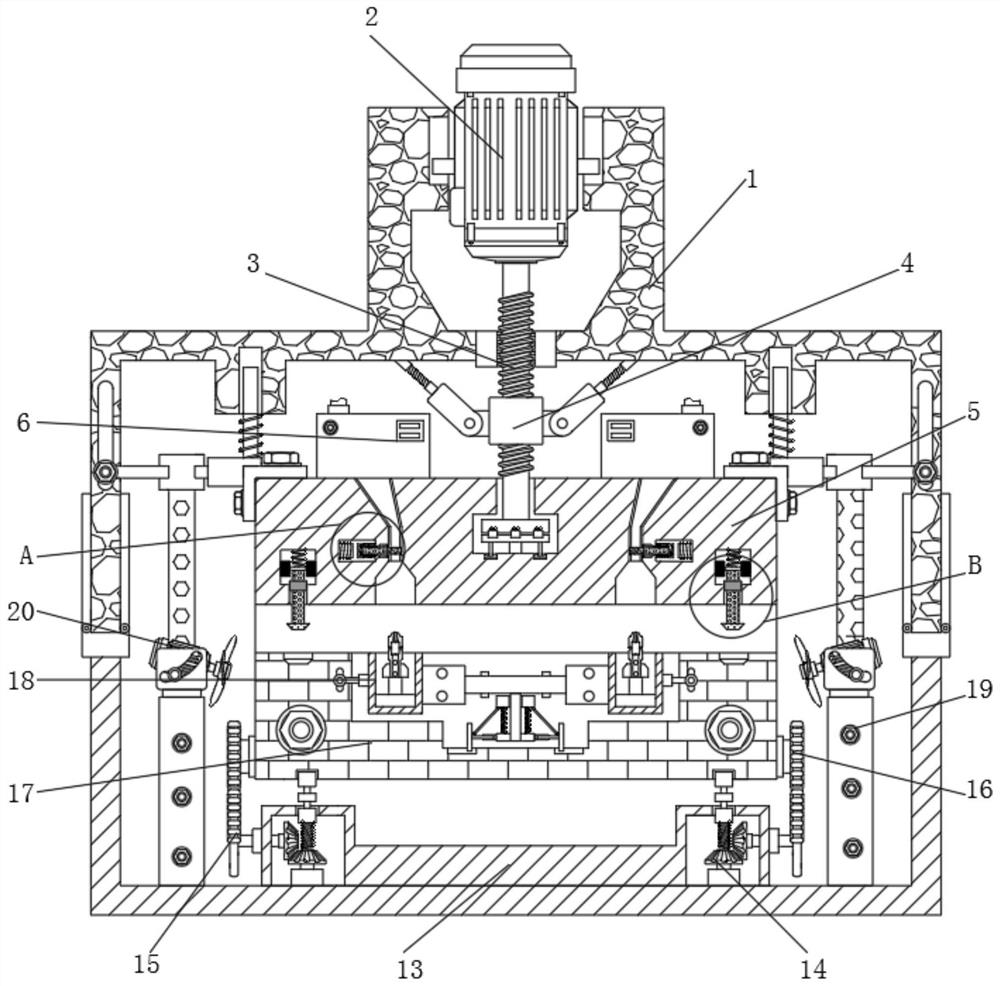

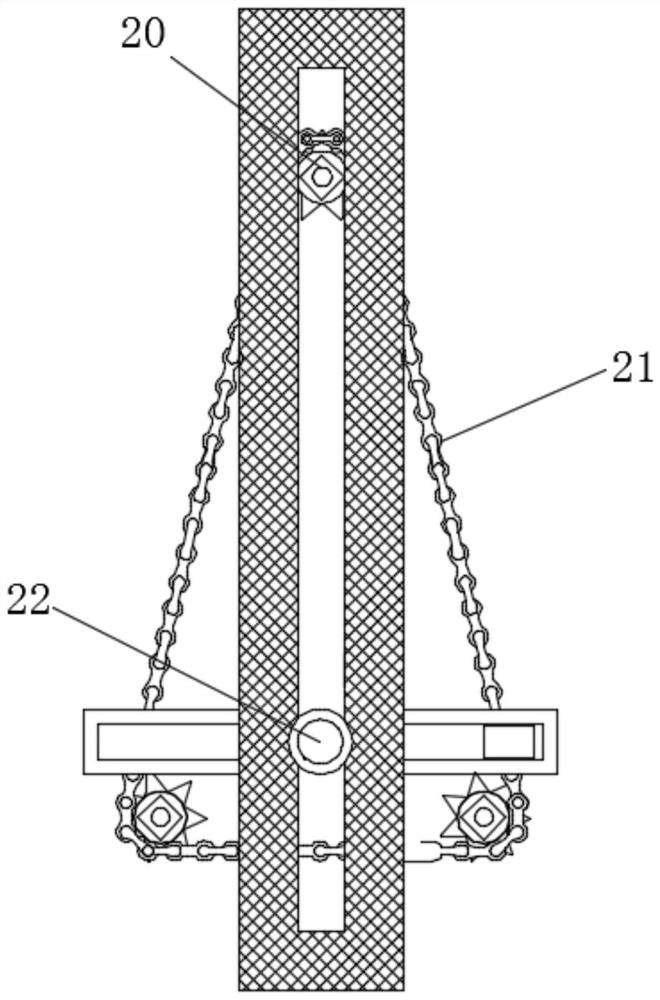

Differential centrifugal ceramic forming machine

The invention relates to the technical field of ceramic forming, and discloses a differential centrifugal ceramic forming machine. The machine comprises a rack, a motor is movably connected to the inner bottom of the rack, and a driving shaft is movably connected to the right side of the motor. A shaft sleeve is movably connected to the upper surface of the driving shaft, and a high-speed gear ismovably connected to the right side of the shaft sleeve. The left side of the shaft sleeve is movably connected with a low-speed gear, and the middle of the shaft sleeve is movably connected with a paddle shift. Slurry is made to abut against the mold wall to form a compact blank through centrifugal force generated by rotation driven by a gear disc, bubbles are concentrated in the middle and finally broken out, and generation of bubbles and pinholes in a product is avoided. The slurry suction speed and the product quality are improved, few large particles can be concentrated on the surface ofthe blank due to differential centrifugation, and inconsistent shrinkage caused by uneven tissue is avoided. During mold opening, a clamping gear rotates reversely, clamping plates move outwards to pull a mold open, and the product can be taken out conveniently through mold opening under the displacement and extrusion effect of compressed air.

Owner:李慧

Manufacturing process for ceramic forming aluminum alloy mold and use method thereof

The invention belongs to the technical field of ceramic forming and particularly discloses a manufacturing process for a ceramic forming aluminum alloy mold and a use method thereof. The surface of the aluminum alloy mold is subjected to special treatment to enable contact performance between the surface of the mold and a clay blank to be similar to that of a gypsum mold. The mold can replace the gypsum mold and is used for ceramic forming, pollution of ceramic waste to the environment is reduced, forming labor intensity can be relieved, production cost is reduced, the blank forming quality is improved, and special-shaped product development and new product development and upgrading are facilitated.

Owner:醴陵市湘成陶瓷制造有限公司

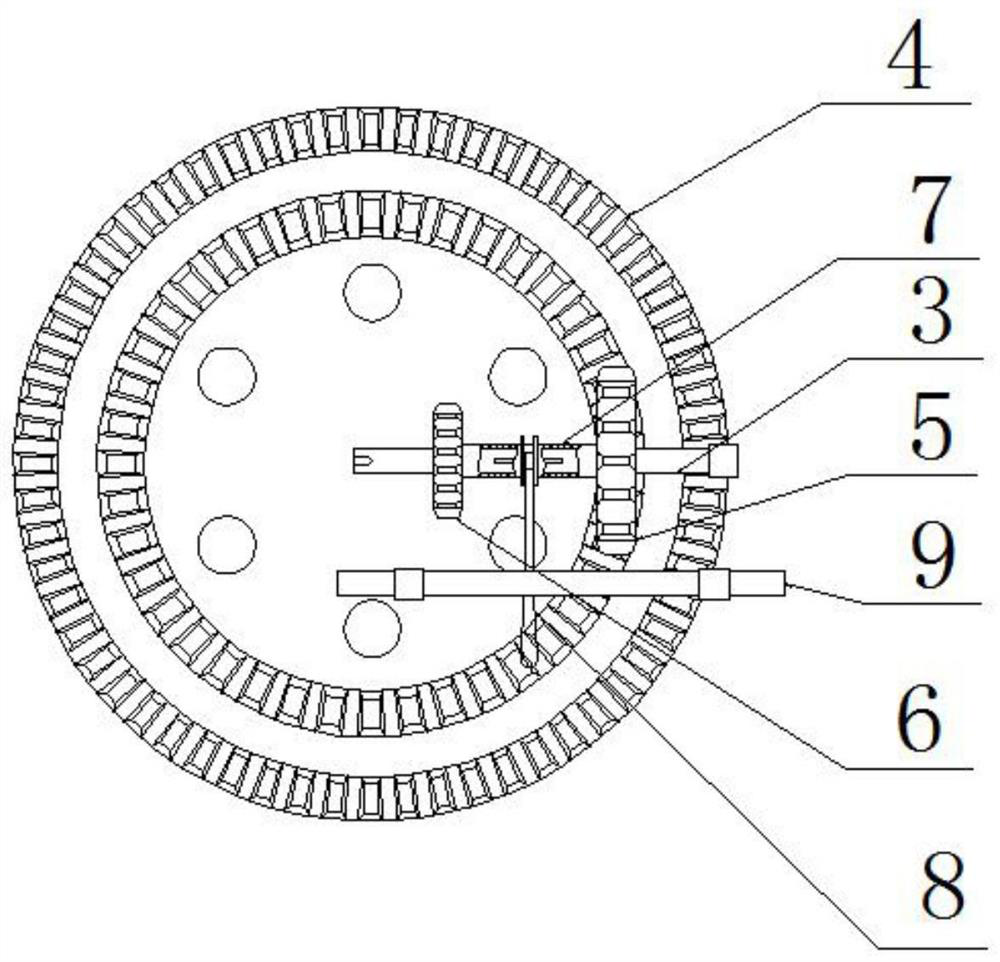

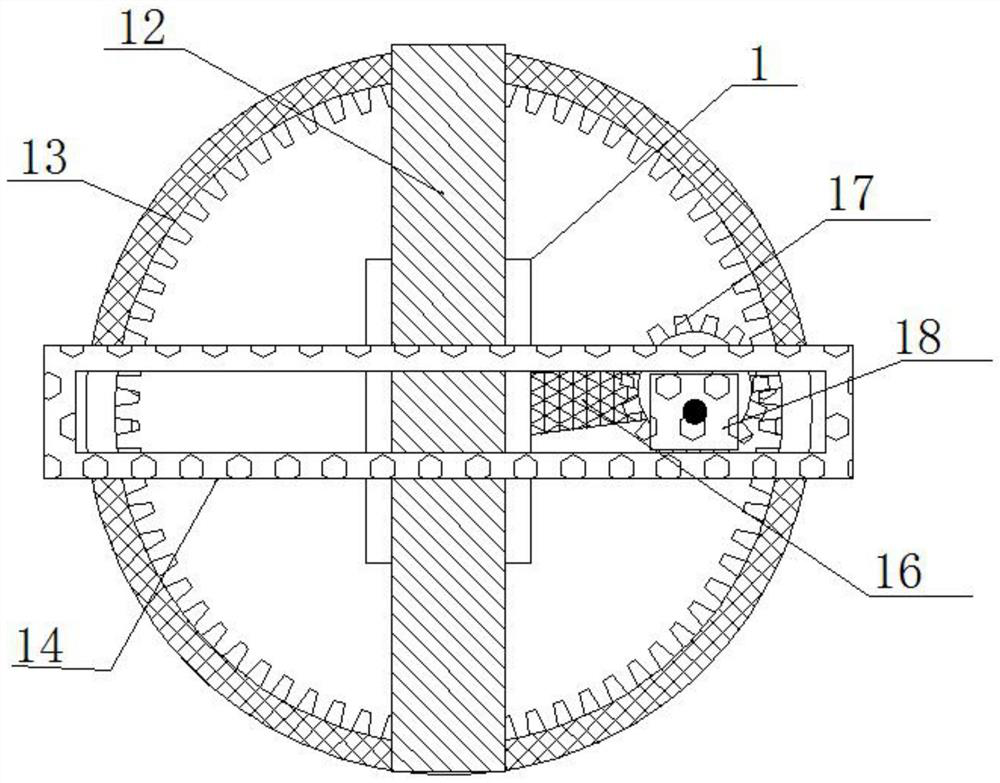

Open ceramic product dry pressing forming device with automatic demolding function

InactiveCN112847740AWith automatic demoulding functionAchieve the effect of automatic demouldingDischarging arrangementRotational axisDrive wheel

The invention relates to the technical field of ceramic forming, and discloses an open ceramic product dry pressing forming device with an automatic demolding function. The open ceramic product dry pressing forming device comprises a machine frame, a motor support is fixedly connected in the machine frame, a lifting mold is connected to the outer side of the motor support in a sliding mode, and a rotating motor is fixedly connected to the upper surface of the interior of the machine frame. According to the open ceramic product dry pressing forming device with the automatic demolding function, a rotating shaft drives a connecting rod to rotate, the connecting rod drives a planet wheel to rotate, the planet wheel drives an eccentric sliding block to rotate, the eccentric sliding block drives a lifting sliding rail to move, the lifting sliding rail drives a lifting mold to move, a rotating motor drives a driving wheel to rotate, and the driving wheel drives a driven wheel to rotate. The driven wheel drives the lower bottom plate to rotate, a transmission assembly drives a lifting rotating shaft to rotate, the lifting rotating shaft drives a rotating crank to rotate, the rotating crank drives a sliding sleeve to rotate, the sliding sleeve drives a pressing block to move, and then by using the lifting mold and other mechanisms in cooperation, the effects of automatic pressing forming and rotating demolding are achieved.

Owner:吴小冰

Liquid phase pretreatment method for gel-casting ceramic blank before binder burning out

The present invention belongs to the field of ceramic forming technology, and is the new liquid phase pre-treatment method of degrading organic matter in biscuit to prevent cracking during eliminating glue. The ceramic biscuit after gel injection molding is liquid phase pre-treated inside water solution o ammonium persulfate or potassium persulfate before eliminating glue. Under the action of peroxide, the polymer inside the ceramic biscuit is chain breaking degraded, the netted macro molecule becomes small molecule and internal stress in the biscuit is released. The biscuit thus treated will not crack and will have no fault during overheat defatting and glue eliminating. The present invention is simple in technological process, low in cost and suitable for industrial production.

Owner:TSINGHUA UNIV

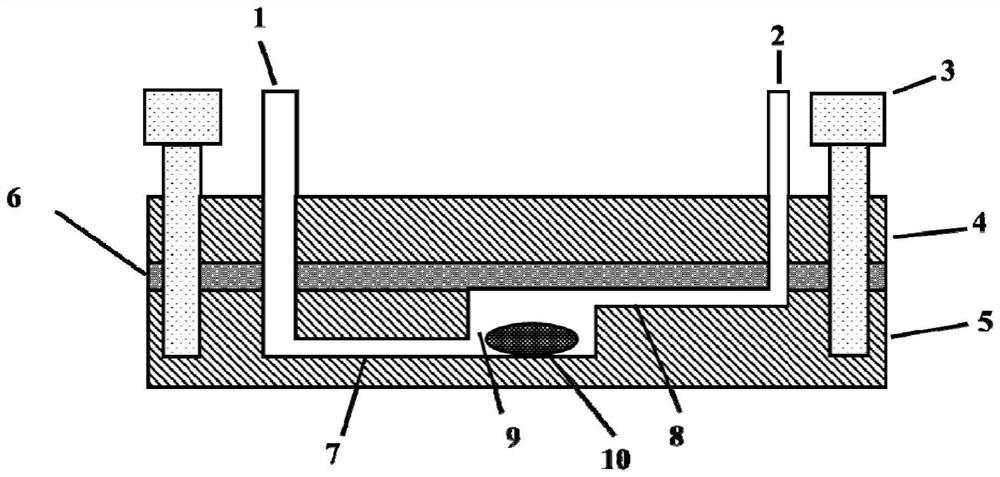

Testing method of ceramic suspended matter gelating point and device

A method and apparatus for measuring the coagulating point of ceramic suspension are based on the principle that the coagulation in situ of ceramic suspension can be induced by heat releasing and external pressure. Said method includes preparing the slurry of ceramic suspension, loading the slurry in mould, putting the pressure applying head and temp sensor in said slurry while attaching pressure sensor to bottom of mould, applying pressure to the slurry, acquiring the data, processing the data by computer program, drawing the relation curve between pressure, temp and coagulating point, and determining the initial coagulating point.

Owner:TSINGHUA UNIV

Novel vacuum degassing method for gelcasting ceramic slurry

Owner:TSINGHUA UNIV

Special mold for ceramic blank high-pressure slip casting process

The invention belongs to the technical field of ceramic molding, and in particular relates to a molding mold for sanitary ceramic blanks; it includes an outer mold and a support plate for sealing the outer mold, and is characterized in that: the outer mold includes a water-absorbing and air-permeable K plaster mold and is arranged on K The steel sleeve of the outer wall of the plaster mold, the steel sleeve is provided with air vents, and the support plate is provided with a grouting port and an air injection port; the special mold for the high-pressure grouting molding process of ceramic blanks adopting the technical solution of the present invention, the strength High is not easy to be damaged by high pressure, and can be permeable and breathable.

Owner:重庆国之四维卫浴有限公司

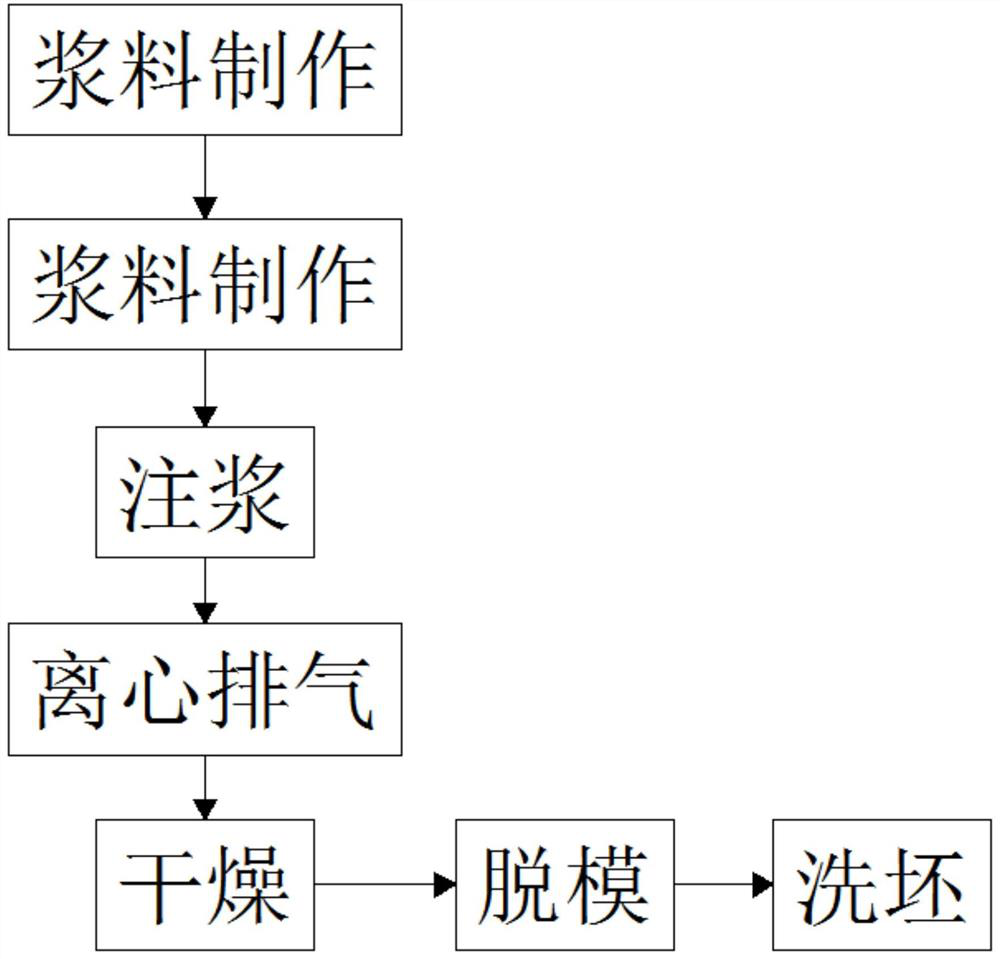

Grouting process

PendingCN113815091AHigh densityQuality improvementCeramic shaping apparatusSlurryCeramic forming techniques

The invention relates to the technical field of ceramic forming, and discloses a grouting process. The process comprises the following steps: step 1, slurry preparation: uniformly mixing and stirring various raw materials according to a ratio to prepare raw material slurry; step 2, mold assembling: selecting a corresponding mold, closing the mold, and then integrally mounting and fixing the mold on a turntable of a centrifugal machine; step 3, grouting, injecting the raw material slurry prepared in the step 1 into a mold cavity of the mold in the step 2 through compressed air pressurization equipment; and 4, centrifugal exhausting: separating a grouting opening of the mold from the compressed air pressurization equipment, and sealing the grouting opening of the mold. According to the grouting process, through the manner of combining pressure grouting and centrifugation, the compactness of a blank can be greatly improved, bubbles and air holes in the blank can be reduced, and the quality of the prepared blank is effectively improved.

Owner:ANHUI PROVINCIAL HANSHAN MINSHENG PORCELAIN

A kind of sheet ceramic forming device and using method thereof

ActiveCN106182337BUniform bulk densityEnsure consistent qualityMould auxillary partsAuxillary shaping apparatusCeramic moldingAcute angle

The invention discloses a sheet-shaped-ceramic forming device and a use method of the sheet-shaped-ceramic forming device and relates to the technical field of forming of sheet-shaped ceramics. The sheet-shaped-ceramic forming device and the use method of the sheet-shaped-ceramic forming device achieve the effects of guaranteeing the quality consistency of products and improving production efficiency. According to the technical scheme, the sheet-shaped-ceramic forming device comprises a base, a platform and a forming mold. The base is provided with a first end face. The platform is arranged on the base in an inclined manner. The platform is provided with a second end face and a third end face opposite to the second end face. The second end face is opposite to the first end face. An included angle between the third end face and the first end face is an acute angle. The forming mold is of a platy structure and is laid on the third end face, and ceramic slurry is poured into the forming mold in an inclined manner.

Owner:CHINA BUILDING MATERIALS ACAD

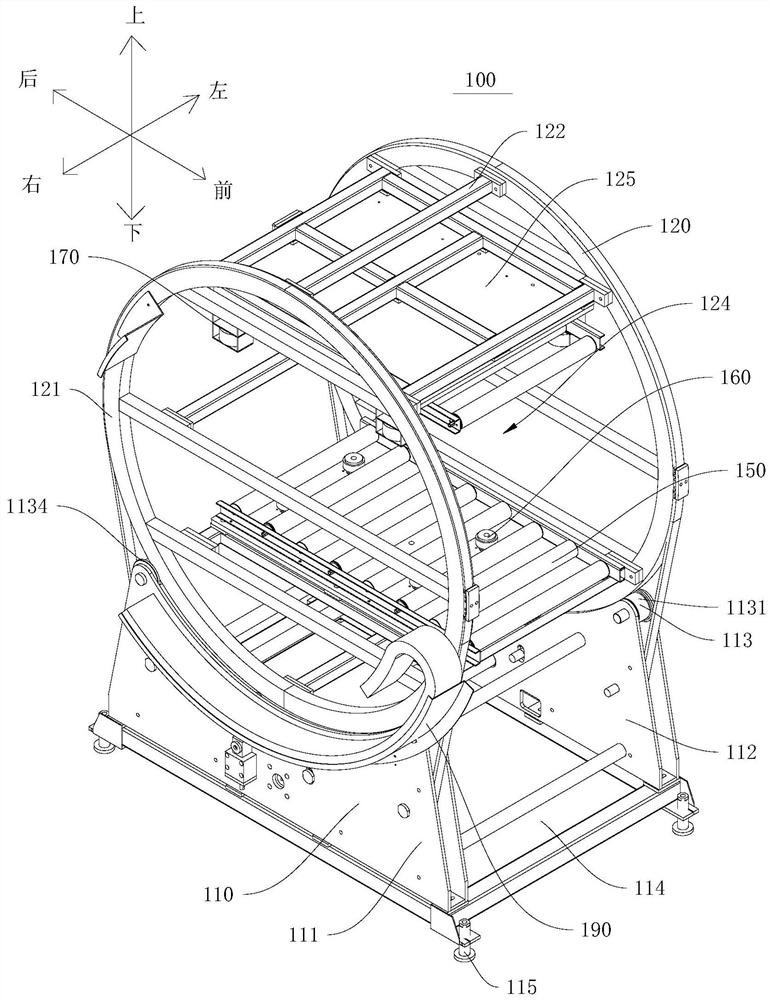

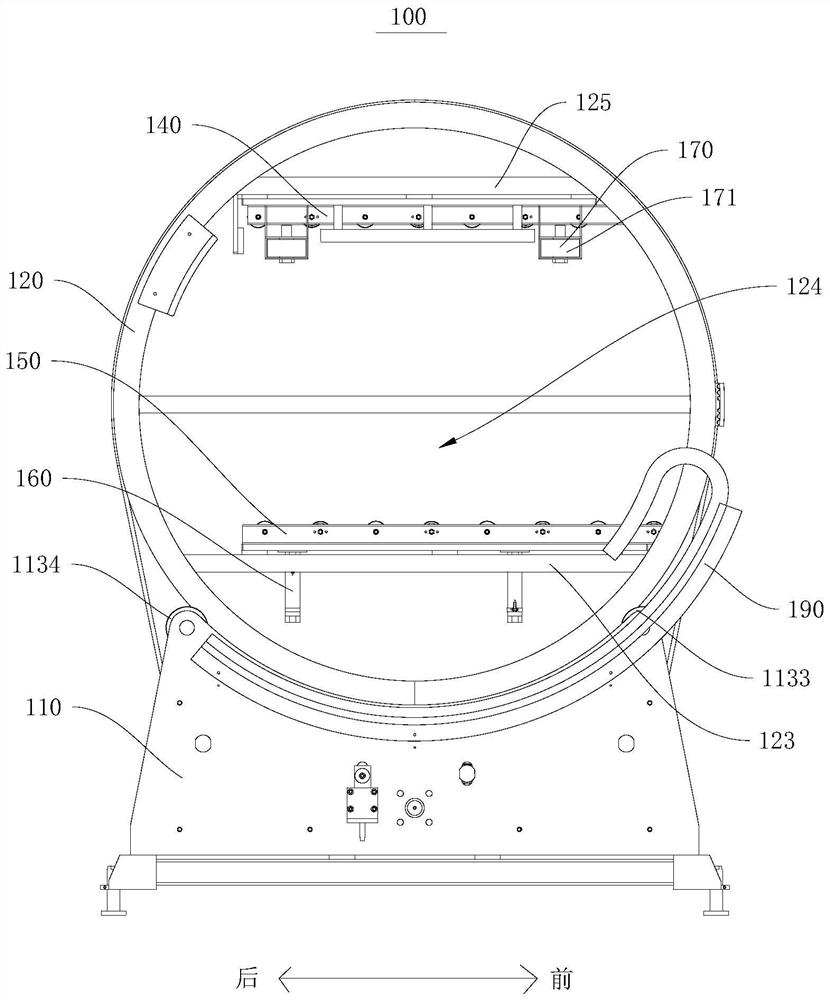

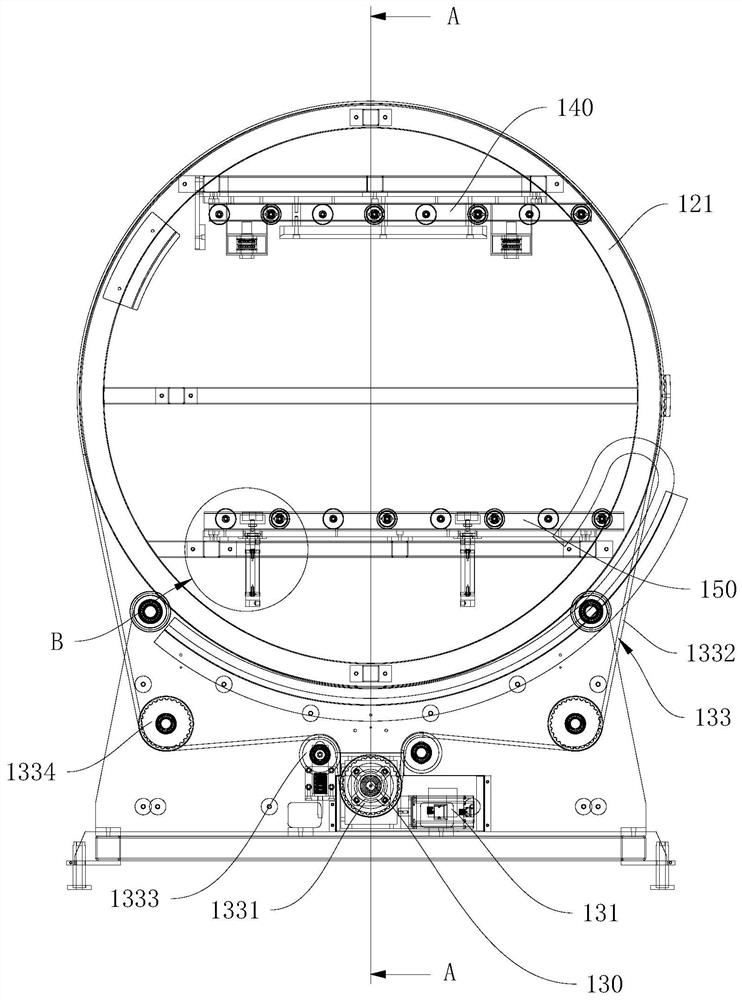

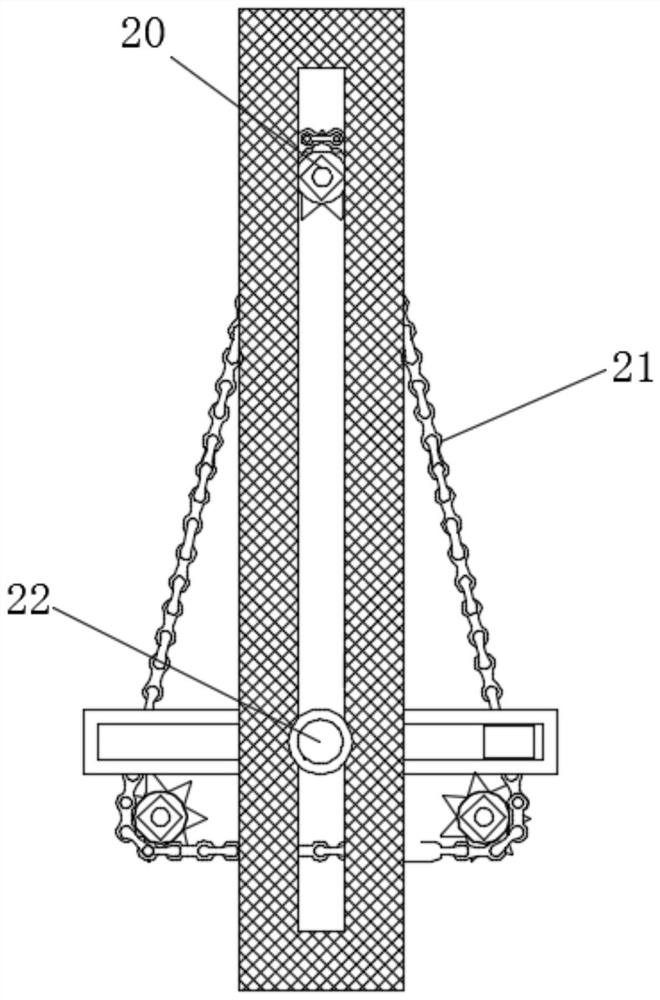

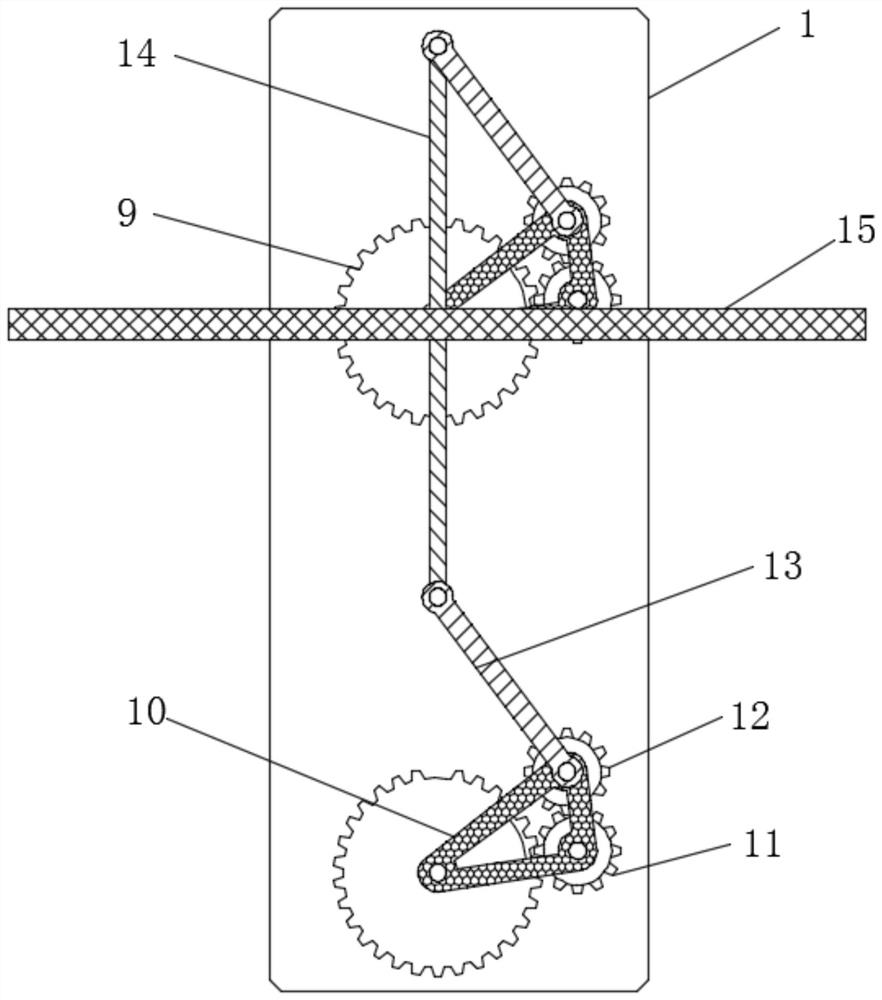

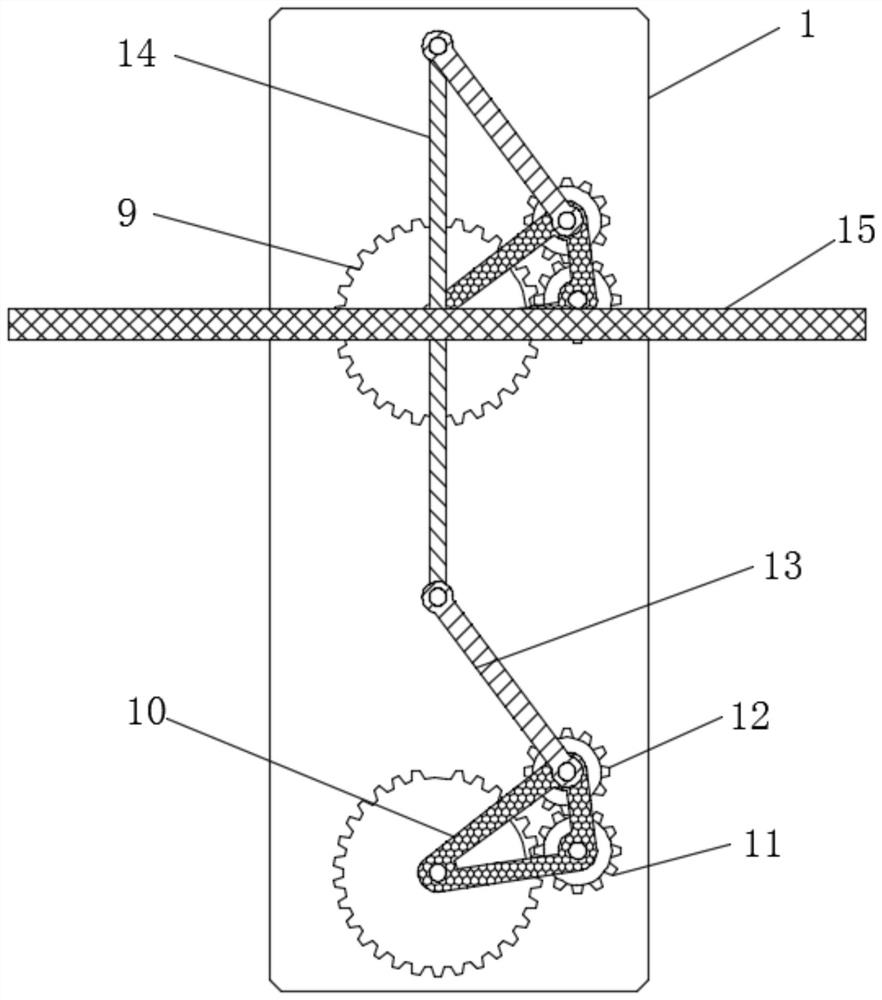

Blank turning machine and blank production line

PendingCN111823384AGuaranteed integrityIncrease productivityCeramic shaping plantsAuxillary shaping apparatusProduction lineCeramic molding

The invention relates to a blank turning machine and a blank production line, and belongs to the technical field of ceramic molding. The invention proposes a blank turning machine, and the blank turning machine comprises a base, a rotating stand, a rotating drive device, a first conveying line, a second conveying line and a compression device, wherein the rotating stand is rotationally supported on the base; the rotating drive device is installed on the base, and the rotating drive device can drive the rotating stand to rotate; the first conveying line and the second conveying line are parallel to each other and arranged in the rotating stand up and down at intervals; the compression device is installed in the rotating stand, the compression device is used to match with the first conveyingline to compress a blank together when the rotating stand is in a feeding position, and the compression device is used to place the blank on the second conveying line when the rotating stand is in adischarging position. The invention also proposes a blank production line, and the blank production line comprises the above blank turning machine. The blank turning machine is used on the blank production line, the blank can be automatically loaded and unloaded, the loading direction and the unloading direction are parallel to each other, the blank is automatically fed in and out, and the integrity of the blank can also be ensured.

Owner:广东金马领科智能科技有限公司

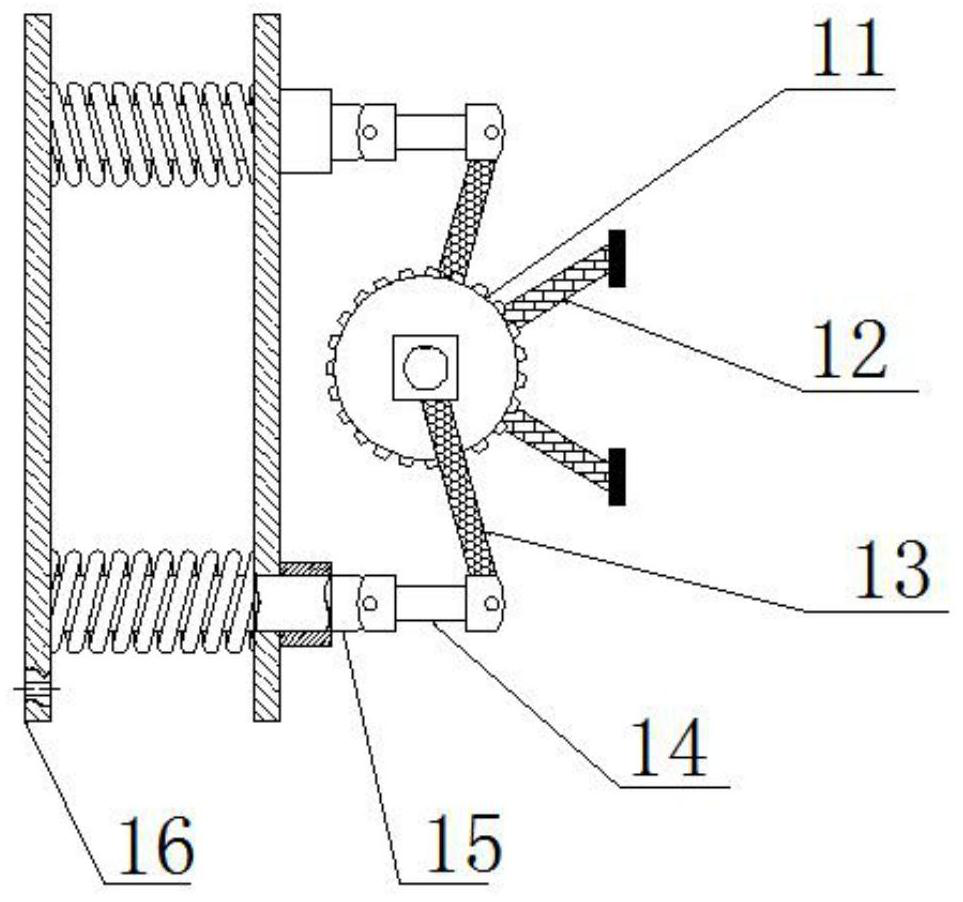

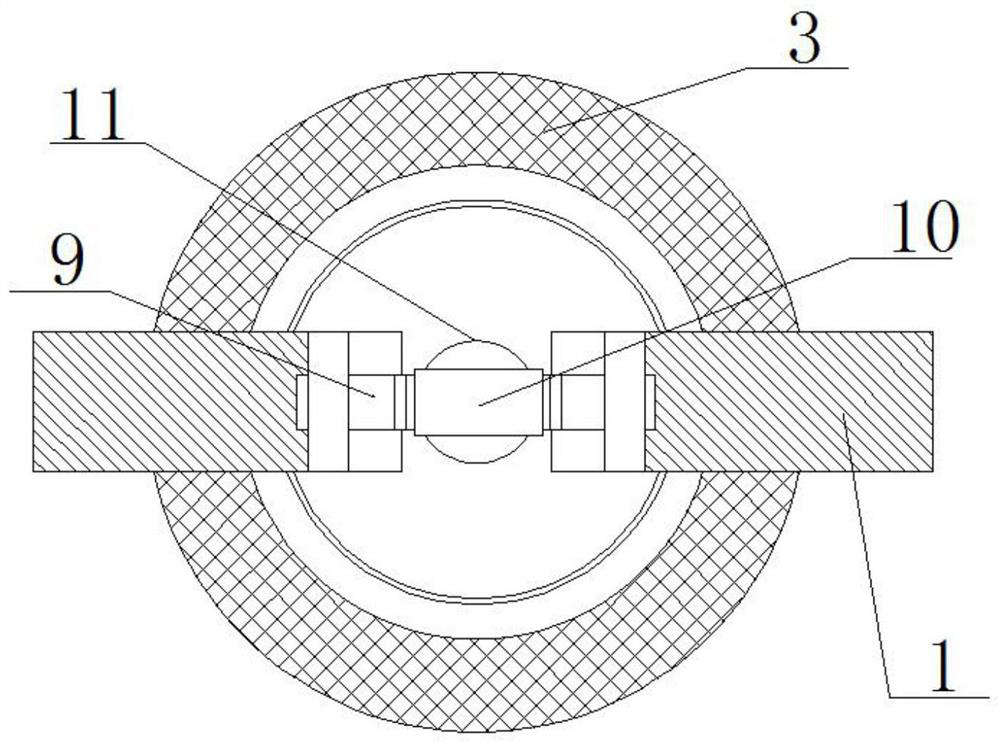

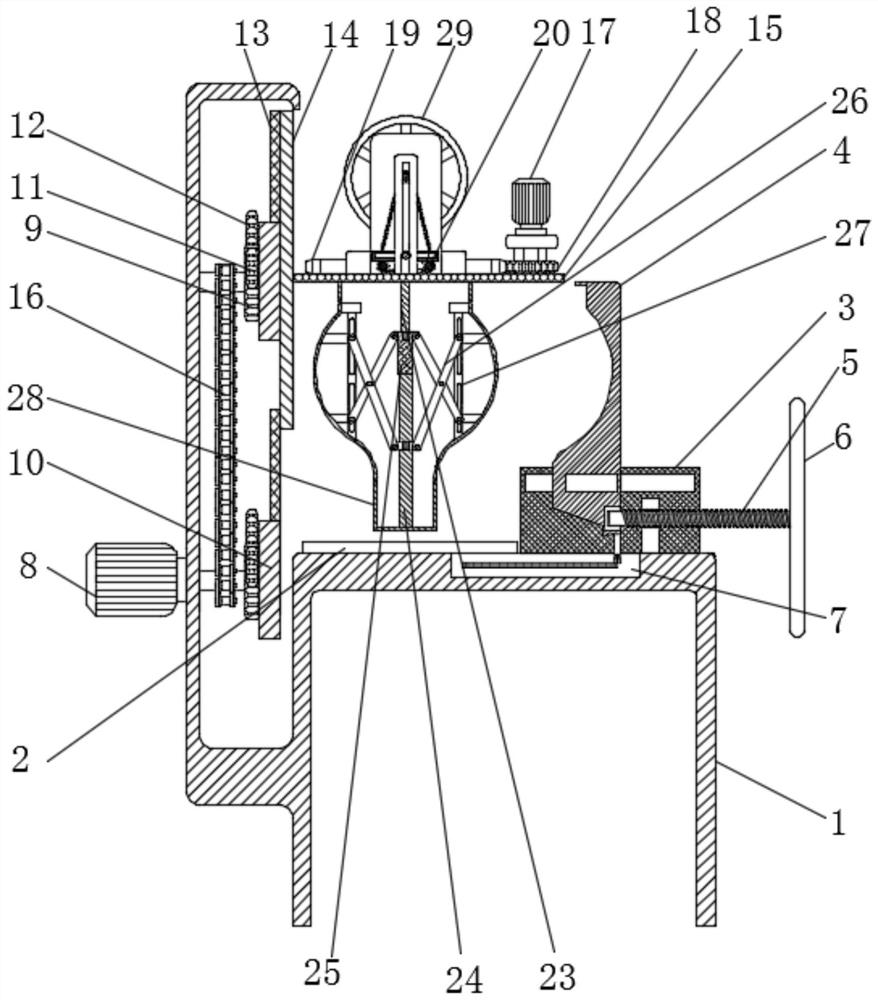

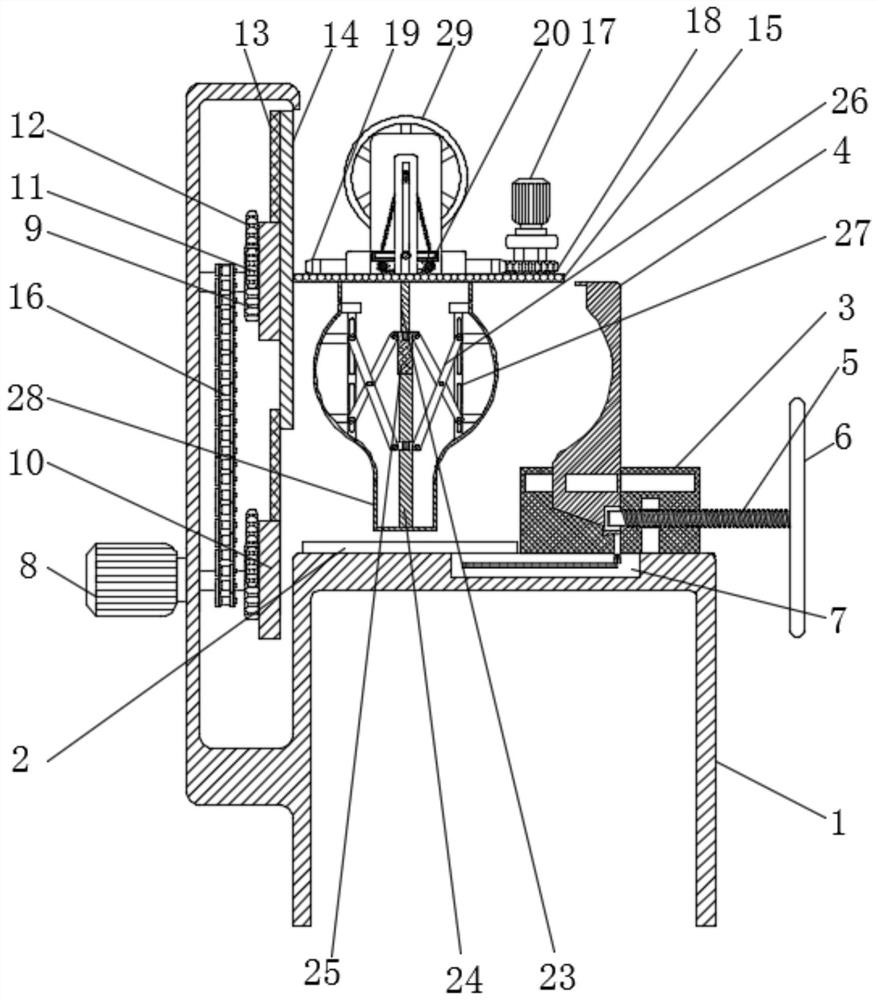

Rapid forming convenient demolding mechanism for long-neck ceramic product

ActiveCN112356222AAchieve manual precision cuttingAchieve the effect of rotary demouldingDischarging arrangementCeramic shaping mandrelsGear wheelElectric machinery

The invention relates to the technical field of ceramic forming, and discloses a rapid forming convenient demolding mechanism for a long-neck ceramic product. The rapid forming convenient demolding mechanism for the long-neck ceramic product comprises a rack; a deck plate and a horizontal sliding groove are fixedly connected to the top of the rack; an indication plate is fixedly connected to the front surface of the rack; and a feeding screw rod is rotationally connected to the top of the rack. According to the rapid forming convenient demolding mechanism for the long-neck ceramic product, a feeding screw rod is driven to rotate through a rotating flange, the feeding screw rod drives a cutting plate to move, and a manual precise cutting effect is achieved through cooperative use of mechanisms such as a horizontal sliding groove, an indicating plate and a fixing mold; and a telescopic lifting rod is driven to move through a lifting flange, the telescopic lifting rod drives a tensioningrod to rotate, the tensioning rod drives the fixing mold to contract, a lifting motor drives a lifting plate to rotate, the lifting plate drives a rotary transmission wheel to move upwards, the rotarytransmission wheel drives the fixing mold to move upwards, and then the automatic contracting, lifting and demolding effect is achieved through cooperative use of mechanisms such as a driving gear.

Owner:QICHUN MINGYAO POTTERY CO LTD

Manufacturing process and application method of aluminum alloy mold for ceramic forming

Owner:醴陵市湘成陶瓷制造有限公司

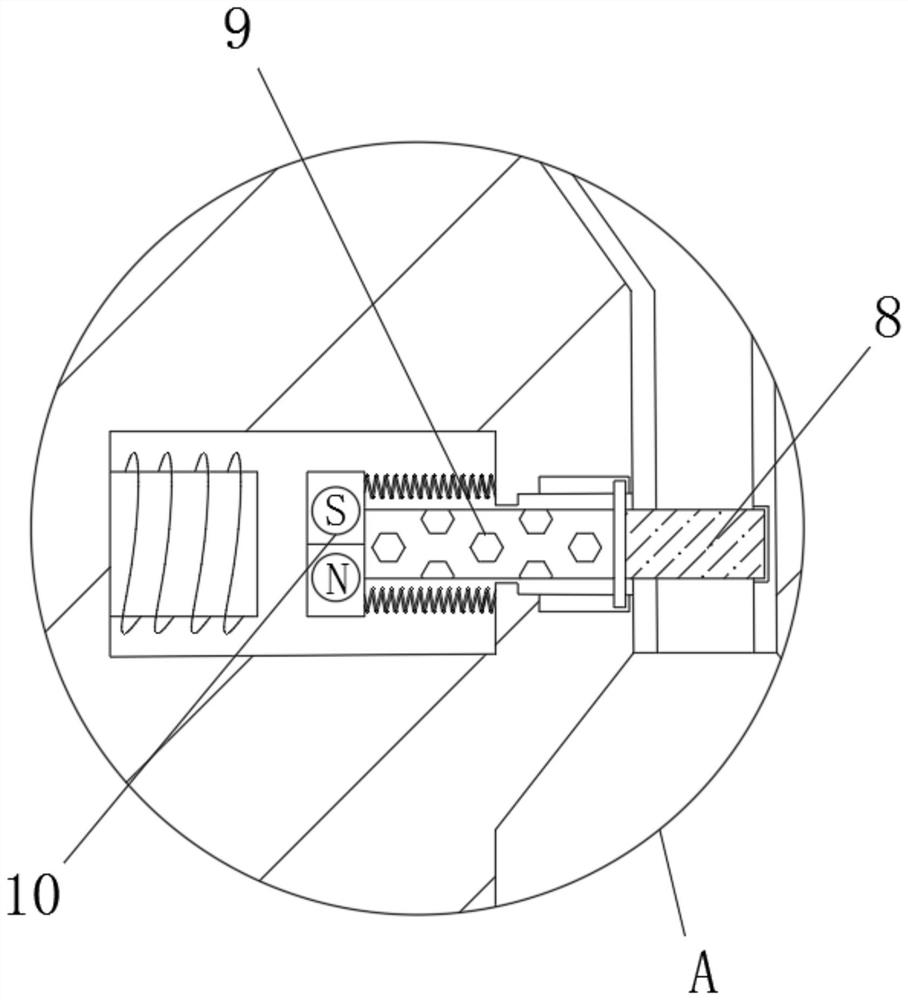

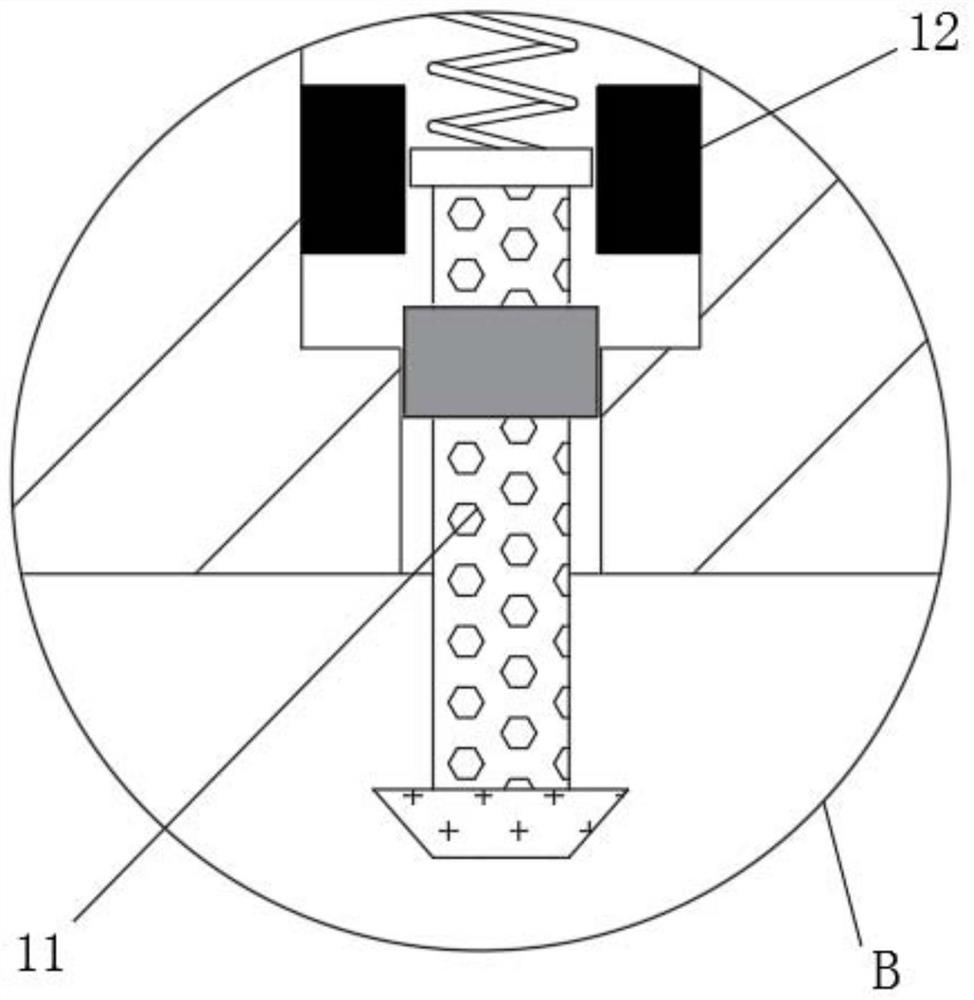

Ceramic nozzle injection molding and rapid cooling demolding device

InactiveCN112936548APrevent the effect of affecting the moldingAchieve automatic demouldingDischarging arrangementFeeding arrangmentsGear wheelElectric machinery

The invention relates to the technical field of ceramic forming, and discloses a ceramic nozzle injection molding and rapid cooling demolding device which comprises a box body. A motor is movably connected to the interior of the box body; a threaded lead screw is movably connected to the lower end of the motor; the threaded lead screw is sleeved with a sealing cover; a permanent magnet is movably connected to the exterior of a pull rod; a positioning device is movably connected to the interior of the sealing cover; a trigger block is movably connected to the interior of the positioning device; a bevel gear is movably connected to the interior of a collecting box; a sector gear is movably connected to the exterior of the bevel gear; the exterior of the sector gear is in meshed connection with a transposition gear; the exterior of the transposition gear is fixedly connected with a sealing seat; the interior of the sealing seat is movably connected with a nozzle mold; and the upper end of a movable rod is movably connected with a cooling fan. The device has the advantages that raw materials can be prevented from dripping and splashing, meanwhile, the cooling time can be shortened, and automatic demolding is achieved after cooling is finished.

Owner:邱坛贵

A rapid prototyping and convenient demoulding mechanism for long-necked ceramic products

ActiveCN112356222BAchieve manual precision cuttingAchieve the effect of rotary demouldingDischarging arrangementCeramic shaping mandrelsDrive wheelCeramic molding

The invention relates to the technical field of ceramic molding, and discloses a rapid prototyping and convenient demolding mechanism for long-necked ceramic products, comprising a rack, a table top and a horizontal chute are fixedly connected to the top of the rack, and the top of the rack is The front side is fixedly connected with an indicator plate, and the top of the frame is rotatably connected with a feed screw. The rapid prototyping and convenient demolding mechanism of this long-necked ceramic product is driven by the rotating flange to drive the feed screw to rotate, and the feed screw drives the cutting plate to move, and then through the cooperation of the horizontal chute, the indicator plate and the fixed mold, so as to achieve The effect of manual precision cutting is that the lifting flange drives the displacement of the retractable lift rod, the retraction lift rod drives the tension rod to rotate, the tension rod drives the fixed mold to shrink, the lift motor drives the lift plate to rotate, and the lift plate drives the rotary drive wheel to move up and rotate. The transmission wheel drives the fixed mold to move up, and then cooperates with the driving gear and other mechanisms to achieve the effect of automatic lifting and demoulding.

Owner:QICHUN MINGYAO POTTERY CO LTD

Ceramic microsphere and preparation method thereof

The invention belongs to the technical field of ceramic molding, and particularly relates to a ceramic microsphere and a preparation method thereof. The ceramic microsphere is obtained from a glue solution through an internal gelation process, wherein the glue solution comprises metal ions, hexamethylenetetramine and urea, and the glue solution also comprises a complexing agent acetylacetone or aderivative thereof. By adding the complexing agent, the stability of the glue solution at normal temperature can be prolonged, the content of urea can be increased, more urea-formaldehyde resin is generated, the supporting effect is improved, the strength of the gel ball is improved, and the situation that the gel ball is broken or even broken in subsequent treatment is avoided. The obtained ceramic microsphere has the advantages of being uniform in size, good in sphericity degree and free of surface cracking, a nozzle is not blocked in the preparation process, the yield is high, and industrial large-scale production can be achieved. Besides, the non-ionic surfactant is adopted to replace an organic solvent in the prior art, so that the wastewater treatment cost is reduced, and the production environment is greatly improved.

Owner:TSINGHUA UNIV

A method for preparing uranium dioxide microspheres at room temperature

ActiveCN111039326BOvercomes the disadvantage of needing to freezeLow thermal conductivityUranium dioxideUranium oxideHexamethylenetetramine

Owner:TSINGHUA UNIV

Glue solution for internal gelation process as well as preparation method and application thereof

The invention belongs to the technical field of ceramic forming, and particularly relates to a glue solution for an internal gelation process as well as a preparation method and application thereof. The glue solution comprises metal ions, hexamethylenetetramine and urea, and also comprises a complexing agent acetylacetone or a derivative thereof. The glue solution can keep good stability at normaltemperature, prolong the storage time, simplify devices and equipment of an internal gelation process, such as cooling equipment, reduce the production cost, and realize glue solution conveying and gelation dispersion of industrial large-scale production; and the formed gel is high in strength, so that the situation that the gel is broken or even fragmented in subsequent treatment is avoided.

Owner:TSINGHUA UNIV

High pressure grouting forming process for ceramic billet

ActiveCN102528898BNot fragileEasy to separateCeramic shaping apparatusSlurryCeramic forming techniques

The invention belongs to the technical field of ceramic forming, in particular relates to a forming process for a bathroom ceramic billet, which comprises the steps: (1) allocating forming materials according to ratio and mixing the forming materials into even slurry; (2) pressing the slurry into a high strength permeable mold, enabling the pressure of the slurry in the permeable mold to be kept at 0.3-1.6MPa for 0.5-5minutes, and enabling the slurry to crust and form the ceramic billet; (3) discharging the slurry left in the high strength permeable mold; (4) blowing compressed air into the high strength permeable mold, and keeping the pressure of the compressed air in the high strength mold at 0.1-0.25MPa for 0.1-1minute; (5) enabling the inside and the outside of the ceramic billet to form pressure difference of 100-1000Pa by increasing the outside pressure of the high strength permeable mold, keeping the pressure difference at no less than 0.1 second, and enabling the ceramic billet to be separated from the high strength permeable mold; and (6) separating the high strength permeable mold to obtain the ceramic billet. By means of the high pressure grouting forming process for the ceramic billet of the technical scheme, required number of the mold is small, and manufacture efficiency and compact evenness of the billet are high.

Owner:重庆国之四维卫浴有限公司

A kind of ceramic microsphere and preparation method thereof

The invention belongs to the technical field of ceramic molding, and in particular relates to a ceramic microsphere and a preparation method thereof. The ceramic microspheres are obtained from a glue solution through an internal gelling process; wherein the glue solution includes metal ions, hexamethylenetetramine and urea; and the glue solution also includes a complexing agent acetylacetone or derivatives thereof. The present invention can not only prolong the stability of the glue solution at normal temperature by adding complexing agent, but also increase the urea content, and then produce more urea-formaldehyde resin to improve the supporting effect, thereby improving the strength of the gel ball and avoiding the occurrence of Cracked or even chipped. The ceramic microspheres obtained by the invention have the advantages of uniform size, good sphericity, and no cracks on the surface, and the nozzles are not blocked during the preparation process, the yield is high, and industrialized large-scale production can be realized. In addition, the invention adopts the non-ionic surface active agent to replace the organic solvent in the existing technology, which not only reduces the waste water treatment cost, but also greatly improves the production environment.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com