Testing method of ceramic suspended matter gelating point and device

A test method and test device technology, applied in the investigation stage/state change, etc., can solve problems such as cracking, affecting the uniformity and reliability of the green body and sintered body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

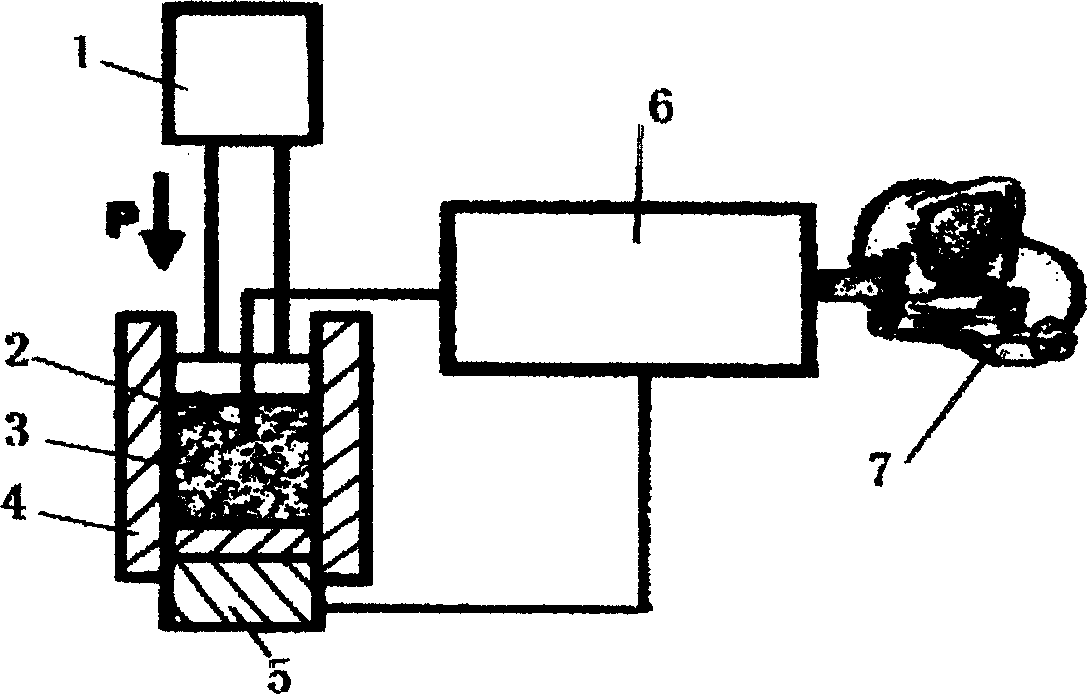

Method used

Image

Examples

Embodiment

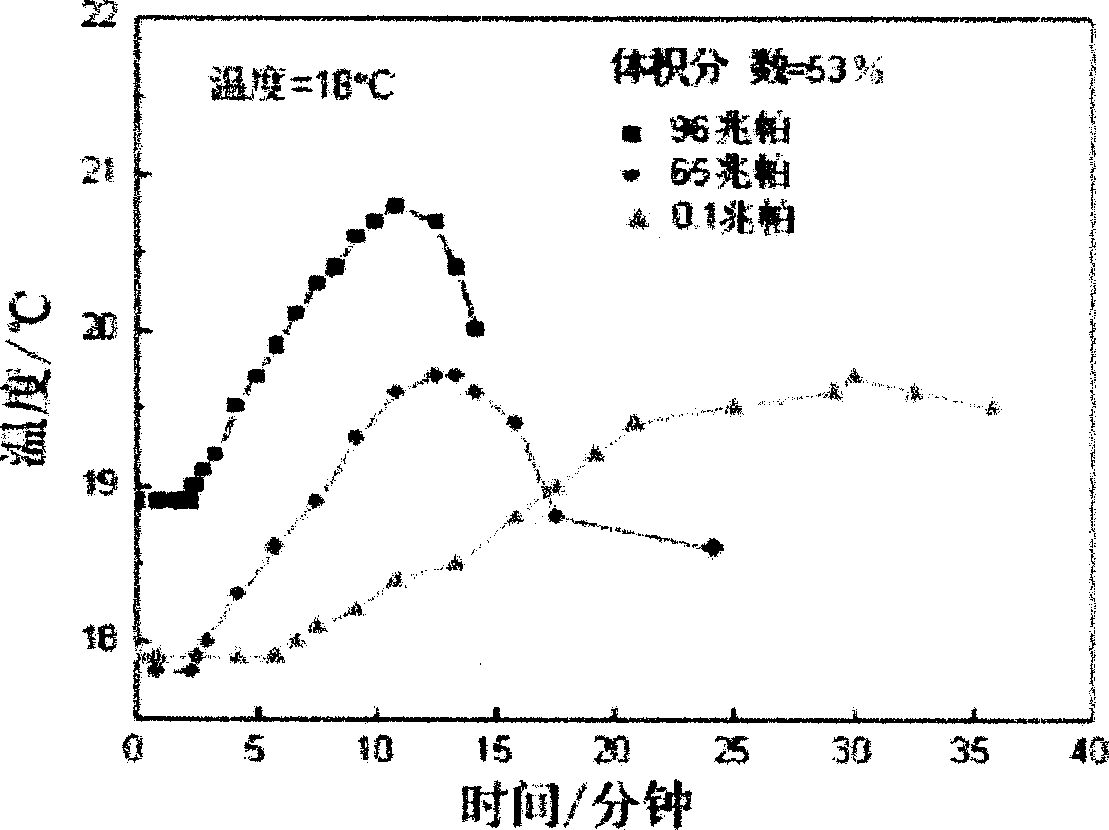

[0023] Disperse the commercially available high-purity (>99.9%) aluminum oxide, zirconium oxide, silicon nitride or monite raw materials with a volume moment average diameter of 0.5 μm and a nearly spherical shape into the premix solution respectively. The following is just an example of aluminum oxide being dispersed in the premix, under the following conditions: in the premix (containing 5%, 10%, 15% or 18.6% of the organic The ratio of methanebisacrylamide and acrylamide is 3:35, 2:50, 1:55 or 1:90, the content of deionized water is from 81.4% to 95%), the volume fraction of preparation is 5vol%, 20vol%, 40vol% or 53vol% ceramic suspension, ball milled for 48 hours, take out 100ml, add 100μl catalyst N,N,N',N'-tetramethylethylenediamine and 250μl initiator ammonium persulfate, and then put it into a constant temperature reaction vessel , Respectively react under normal pressure, 65MPa, 96MPa. Through the data collection and analysis system, such as figure 2 The curve sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com