Special mold for ceramic blank high-pressure slip casting process

A high-pressure grouting and forming technology, applied in the direction of molds, etc., can solve the problems of slow crust formation, insufficient compactness, and reduced strength of gypsum molds, and achieve the effects of preventing damage, high strength, good water absorption and air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

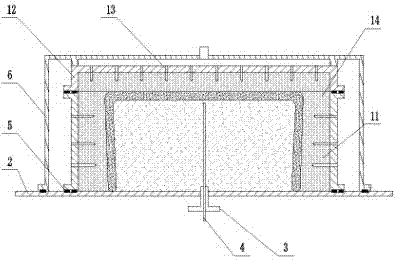

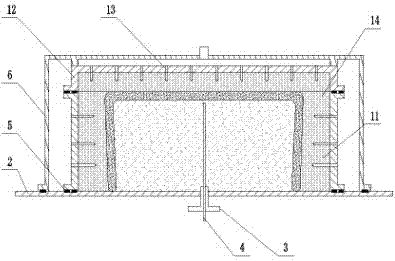

[0016] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

[0017] like figure 1 As shown, the present invention provides a special mold for the high-pressure grouting molding process of ceramic blanks, including an outer mold composed of two half molds, a booster cover 6 and a support plate 2 for sealing the outer mold and the booster cover 6, and the outer mold It includes a water-absorbing and breathable K plaster mold 11 and a steel sleeve 12 arranged on the outer wall of the K plaster mold. The steel sleeve 12 is provided with air holes 13, and the outer surface of the K plaster mold 11 is provided with corresponding air holes 13 on the steel sleeve 12. The blind hole 14, the diameter of the blind hole 14 can be selected between 0.5 ~ 2mm according to the size of the mold, the bottom of the blind hole 14 is 1cm away from the inner surface of the K plaster mold 11, and the support plate 2 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com