A kind of ceramic microsphere and preparation method thereof

A technology of ceramic microspheres and gel spheres, applied in the field of ceramic molding, can solve the problems of inability to realize large-scale application of an internal gelation process, increase the cost of wastewater treatment, reduce the output of ceramic microspheres, etc., so as to improve the production environment and reduce wastewater. Treatment cost, effect of prolonging stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

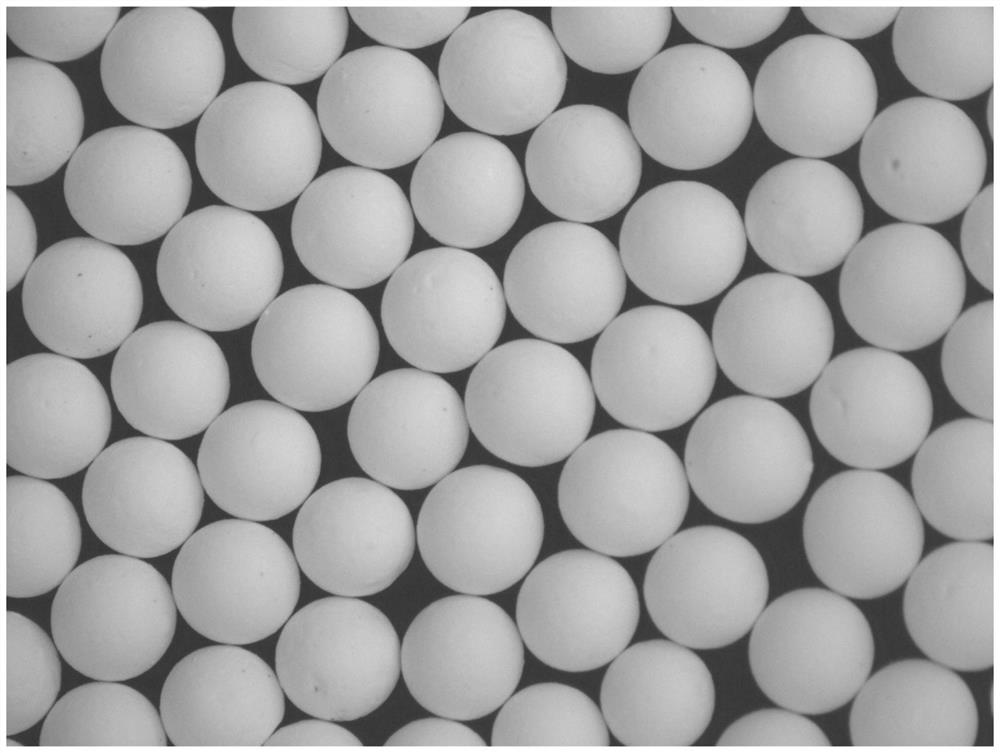

Image

Examples

Embodiment 1

[0056] Embodiment 1 A kind of preparation method of ceramic microspheres (do not contain additive in the glue solution)

[0057] The present embodiment provides a kind of preparation method of ceramic microspheres, comprising:

[0058] (1) At room temperature, add 3 mol of hexamethylenetetramine and 3 mol of urea into deionized water and mix evenly to prepare a 1 L mixed solution to form the first mixed solution;

[0059] (2) Dissolve U3O8 in concentrated nitric acid at room temperature and add deionized water to prepare a 2.8M uranyl nitrate solution with a pH value of 1.8-2.2;

[0060] Take 5ml of the uranyl nitrate solution, add 1ml of complexing agent acetylacetone dropwise into the solution and mix evenly to form the second mixed solution;

[0061] (3) Take the first mixed solution and the second mixed solution and mix them uniformly at a volume ratio of 1:1 to form a third mixed solution to obtain the glue.

[0062] In the obtained glue solution: 1.4 mol / L of metal ion...

Embodiment 2

[0075] Embodiment 2 A kind of preparation method of ceramic microsphere (containing additive in the glue)

[0076] The present embodiment provides a kind of preparation method of ceramic microspheres, comprising:

[0077] (1) At room temperature, add 3 mol of hexamethylenetetramine and 3 mol of urea into deionized water and mix evenly to prepare a 1 L mixed solution to form the first mixed solution;

[0078] (2) Dissolve U3O8 in concentrated nitric acid at room temperature and add deionized water to prepare a 2.8M uranyl nitrate solution with a pH value of 1.8-2.2;

[0079] Dissolve 1.8g of glucose in 1ml of complexing agent acetylacetone, add 5ml of uranyl nitrate solution into the solution and mix evenly to form the second mixed solution;

[0080] (3) Take 6ml of the first mixed solution and mix them evenly with the second mixed solution at a volume ratio of 1:1 to form the third mixed solution to obtain the glue.

[0081] In the obtained glue solution: metal ion 1.4mol / L,...

Embodiment 3

[0092] Embodiment 3 A kind of preparation method of ceramic microspheres (glucose, carbon powder are contained in the glue solution)

[0093] The present embodiment provides a kind of preparation method of ceramic microspheres, comprising:

[0094] (1) At room temperature, add 3 mol of hexamethylenetetramine and 3 mol of urea into deionized water and mix evenly to prepare a 1 L mixed solution to form the first mixed solution;

[0095] (2) Dissolve U3O8 in concentrated nitric acid at room temperature and add deionized water to prepare a 2.8M uranyl nitrate solution with a pH value of 1.8-2.2;

[0096] Dissolve 1.8g of glucose in 1ml of complexing agent acetylacetone, add 5ml of uranyl nitrate solution into the solution and mix evenly to form the second mixed solution;

[0097] (3) Mix the 6ml of the first mixed solution with the second mixed solution in a volume ratio of 1:1 to form a third mixed solution;

[0098] (4) Add 0.17g of carbon powder to the above mixed solution, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com