Device for preparing large-size monodisperse uranium dioxide microspheres

A uranium dioxide, monodisperse technology, applied in the direction of microsphere preparation, gel preparation, microcapsule preparation, etc., can solve the problem of poor sphericity of ceramic microspheres and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

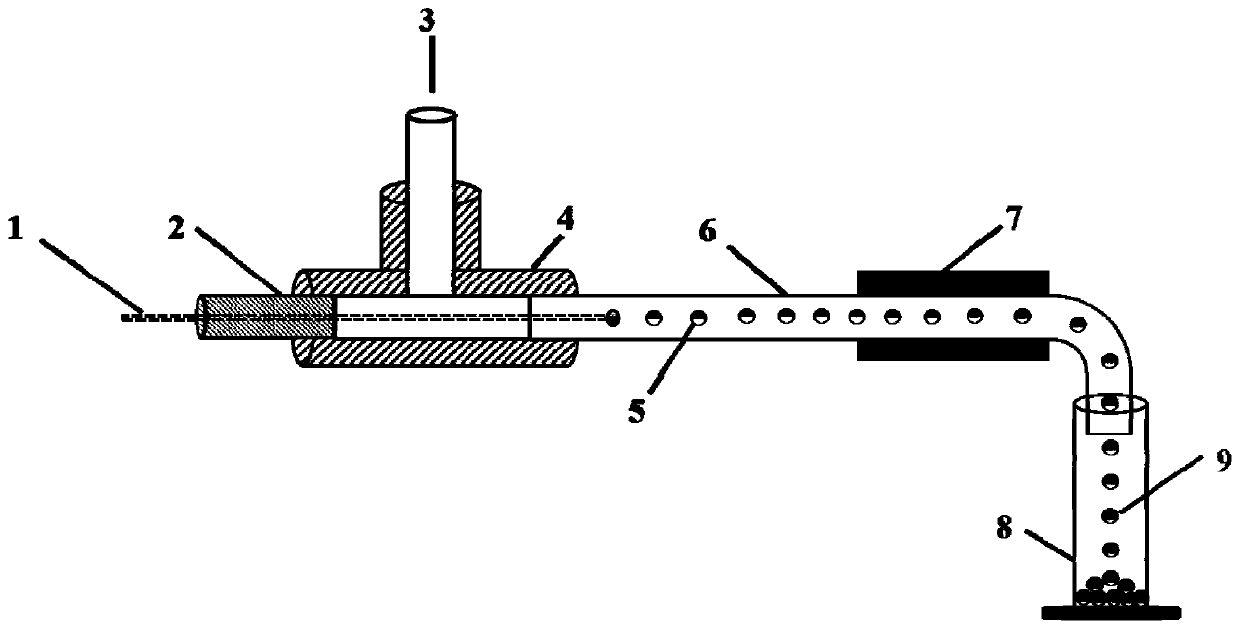

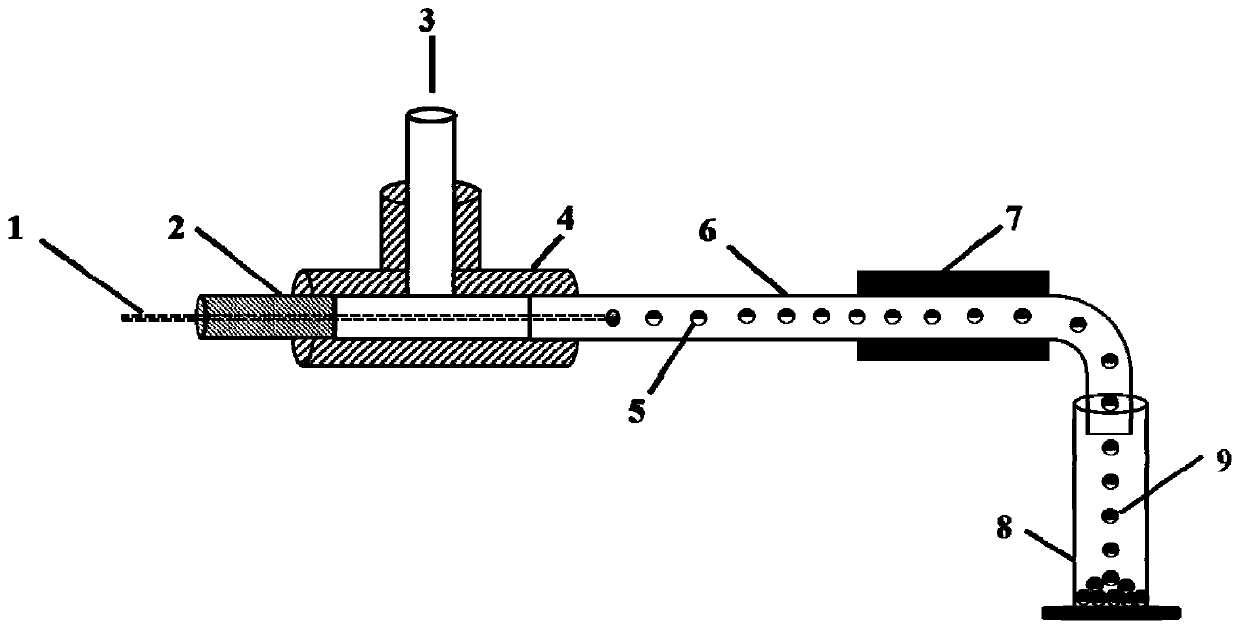

[0011] The device for preparing large-size monodisperse uranium dioxide microspheres proposed by the present invention has a structure such as figure 1 As shown, it includes a dispersed phase fluid inlet pipe 1, a sleeve pipe 2, a continuous phase fluid inlet pipe 3, a T-shaped tee 4, an outlet pipe 6, a water bath 7 and a silicone oil cylinder 8; the dispersed phase fluid inlet pipe 1 extends Into the sleeve pipe 2, one end of the sleeve pipe 2 and the outlet pipe 6 communicate with each other in the lower horizontal pipe of the T-shaped tee 4, and the continuous phase fluid inlet pipe 3 extends from the upper straight pipe of the T-shaped tee 4 The other end of the outlet pipe 6 communicates with the silicone oil cylinder 7; the water bath 7 is set on the outlet pipe 6.

[0012] Below in conjunction with accompanying drawing, introduce working principle and working process of the device of the present invention in detail:

[0013] Such as figure 1 As shown, 1 is the disper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com