A method for preparing uranium dioxide microspheres at room temperature

A technology of uranium dioxide and microspheres, which is applied in the field of preparation of uranium dioxide microspheres at room temperature, can solve the problems of unsatisfactory mixing effect, uneven size, poor sphericity of gel microspheres, etc., and achieve the effect of weakening heat conduction, Uniform size and good sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

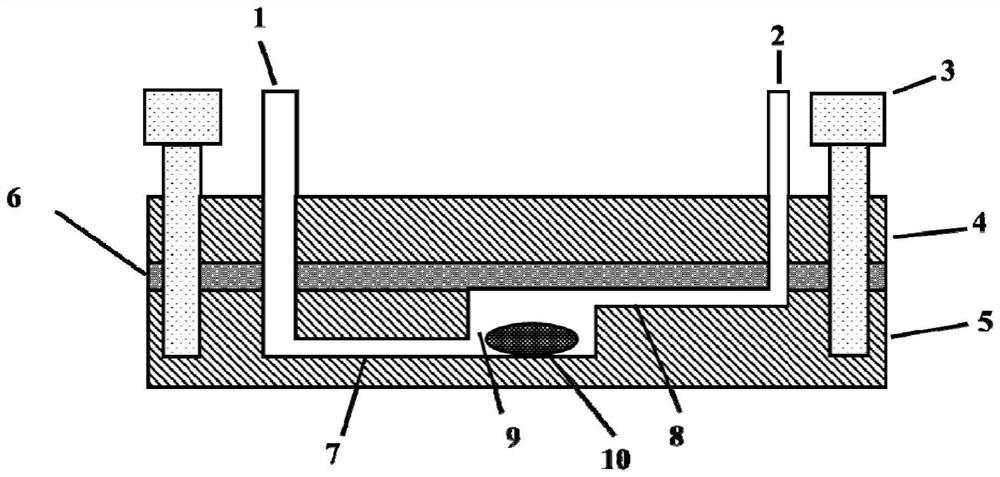

Image

Examples

Embodiment 1

[0029] (1) will U 3 o 8 Powder and HNO with a molar concentration of 16mol / L 3 Mixing, the mass volume ratio of mixing is: U 3 o 8 Powder:HNO 3 =1:0.44g / mL, add deionized water to the mixture, heat and dissolve at 80°C for 2 hours, and make U 3 o 8After the powder is completely dissolved, cool to 20°C, filter, add deionized water to the filtrate to obtain a uranyl nitrate solution with a concentration of 2.8mol / L, which is recorded as the first mixed solution, and cool the prepared first mixed solution to 5°C, set aside;

[0030] (2) preparation molar concentration is the hexamethylenetetramine (HMTA) of 3mol / L and the mixed solution of the urea (Urea) that molar concentration is 3mol / L, the volume ratio of mixing is: hexamethylenetetramine: urea =1:1, the second mixed solution is obtained, and the second mixed solution is cooled to 5°C for subsequent use;

[0031] (3) inject the first mixed solution and the second mixed solution into the container at the same time at ...

Embodiment 2

[0037] (1) will U 3 o 8 Powder and HNO with a molar concentration of 16mol / L 3 Mixing, the mass volume ratio of mixing is: U 3 o 8 Powder:HNO 3 =1:0.44, add deionized water to the mixture, heat and dissolve at 80°C for 2 hours, and make U 3 o 8 After the powder is completely dissolved, cool to 20°C, filter, add deionized water to the filtrate to obtain a uranyl nitrate solution with a concentration of 2.8mol / L, which is recorded as the first mixed solution, and cool the prepared first mixed solution to 5°C, set aside;

[0038] (2) preparation molar concentration is the hexamethylenetetramine (HMTA) of 3mol / L and the mixed solution of the urea (Urea) that molar concentration is 3mol / L, the volume ratio of mixing is: hexamethylenetetramine: urea =1:1, the second mixed solution is obtained, and the second mixed solution is cooled to 5°C for subsequent use;

[0039] (3) inject the first mixed solution and the second mixed solution into the container at the same time respec...

Embodiment 3

[0045] (1) will U 3 o 8 Powder and HNO with a molar concentration of 16mol / L 3 Mixing, the mass volume ratio of mixing is: U 3 o 8 Powder:HNO 3 =1:0.44, add deionized water to the mixture, heat and dissolve at 80°C for 2 hours, and make U 3 o 8 After the powder is completely dissolved, cool to 20°C, filter, add deionized water to the filtrate to obtain a uranyl nitrate solution with a concentration of 3mol / L, which is recorded as the first mixed solution, and the prepared first mixed solution is cooled to 5℃, standby;

[0046] (2) preparation molar concentration is the hexamethylenetetramine (HMTA) of 3mol / L and the mixed solution of the urea (Urea) that molar concentration is 3mol / L, the volume ratio of mixing is: hexamethylenetetramine: urea =1:1, the second mixed solution is obtained, and the second mixed solution is cooled to 5°C for subsequent use;

[0047] (3) inject the first mixed solution and the second mixed solution into the container at the same time at a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com