Cermic Sizing material fast and controllable solidfying colloied state shaping method and device

A technology of ceramic slurry and molding method, applied in ceramic molding machines, chemical instruments and methods, cement mixing devices, etc., can solve the problems of long curing time, slurry curing, uncured, etc., and achieve short curing time and uniform curing. , the effect of a high level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

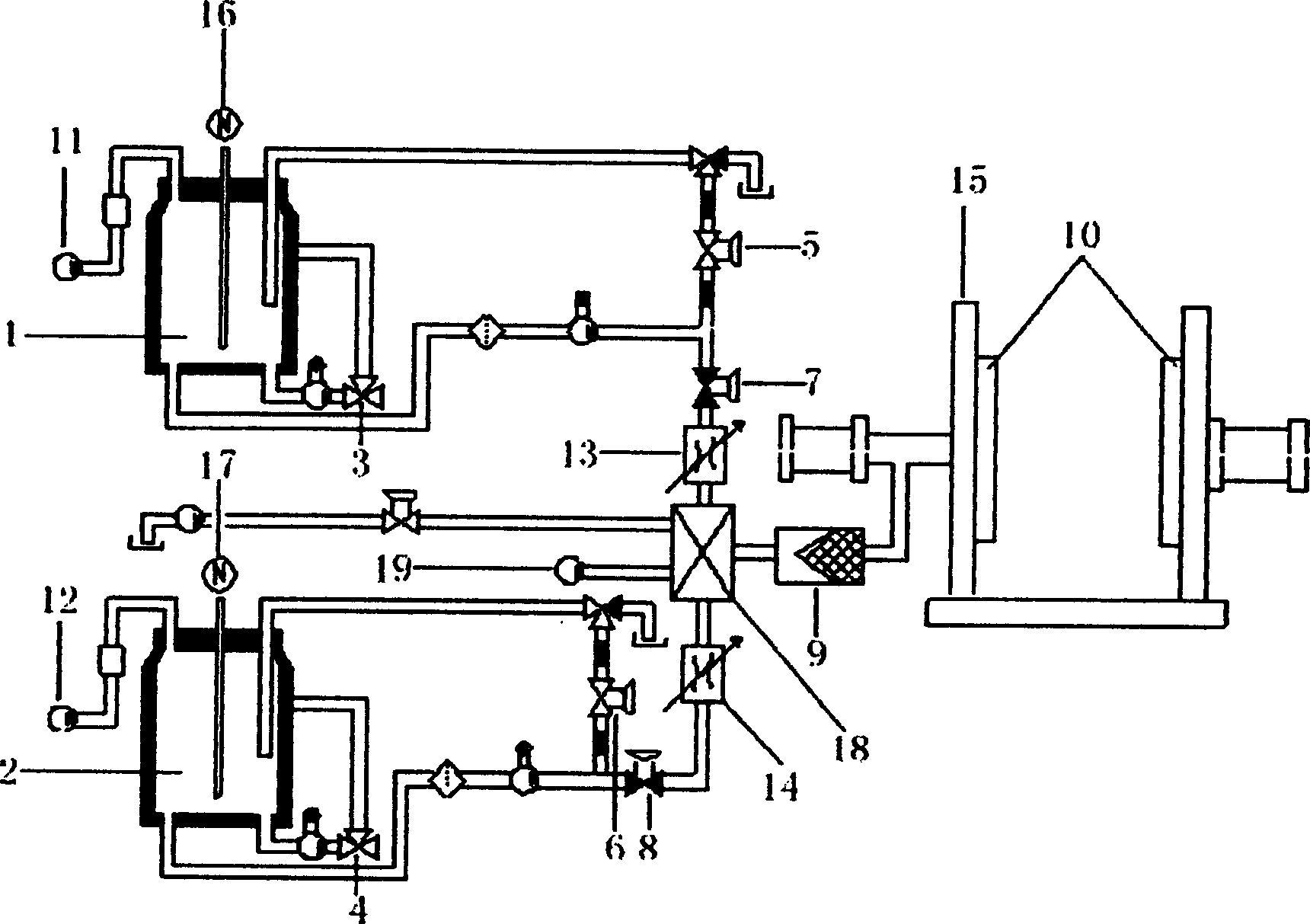

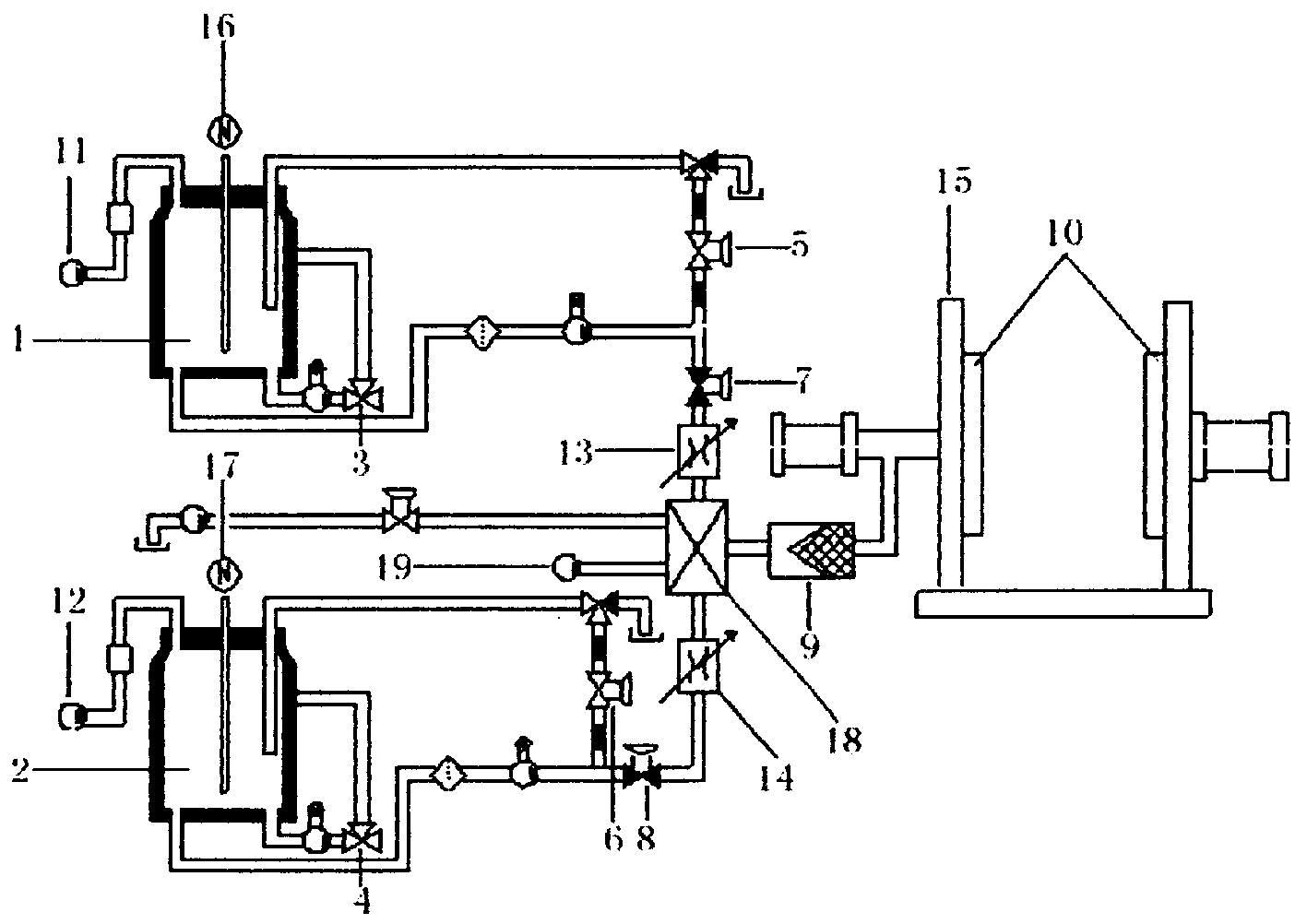

[0040] Example 1 Forming of alumina ceramics

[0041] α-Al 2 o 3 It is a commercially available industrial raw material, the diameter of the particles is about 2 μm, and the shape is relatively uniform. Use hydrochloric acid in deionized water to adjust the pH value between 3.5 and 4, add 6Kg of alumina ceramic powder, and after ball milling for 24 hours, prepare a suspension with a viscosity of 280mPa·s and a volume fraction of 60%, and place it in material A In the tank, the alumina is now positively charged. Use ammonium citrate as a dispersant in deionized water, the pH value is between 5 and 6, add 6Kg of alumina ceramic powder, and after ball milling for 24 hours, prepare a suspension with a viscosity of 200mPa·s and a volume fraction of 60%. , placed in the B material tank, at this time due to the adsorption of ammonium citrate, the alumina is negatively charged. The slurry in the two material tanks of A and B is measured 50ml by the diaphragm metering pump, injecte...

Embodiment 2

[0042] Example 2 Forming of alumina ceramics

[0043] α-Al 2 o 3 It is a commercially available industrial raw material, the diameter of the particles is about 0.5 μm, and the shape is spherical. Use hydrochloric acid in 1000ml of deionized water to adjust the pH value between 3.5 and 4, add 6Kg of alumina ceramic powder and 5g of calcium chloride electrolyte of 0.4mmol / l, and after ball milling for 24 hours, the viscosity is 360mPa·s. The suspension with a volume fraction of 60% is placed in tank A, and the alumina is positively charged at this time. Use 5g of ammonium citrate as a dispersant in 1000ml of deionized water, the pH value is between 5 and 6, add 6Kg of alumina ceramic powder and 5g of ammonium sulfate electrolyte of 0.4mmol / l, and after ball milling for 24 hours, the viscosity is prepared. 300mPa·s, a suspension with a volume fraction of 60%, is placed in material tank B, and the alumina is negatively charged due to the adsorption of ammonium citrate. The slu...

Embodiment 3

[0044] Example 3 Forming of silicon carbide ceramics

[0045] SiC is a commercially available industrial raw material, and the particle diameter is about 0.7 μm. A premix containing 16 wt% of acrylamide monomer and methylenebisacrylamide was prepared with deionized water. The ratio of methylenebisacrylamide to acrylamide is 1:12. Group A powders use the premix to prepare a 55 vol% silicon carbide ceramic thick suspension, and add the catalyst tetramethylethylenediamine at the same time. After 24 hours of ball milling, the viscosity is less than 100 mPa·s. Component B is directly prepared with deionized water to prepare a concentrated suspension of silicon carbide ceramics with a volume fraction of 55vol%. At the same time, add 5g of initiator ammonium persulfate or hydrogen peroxide. After 24 hours of ball milling, the viscosity is less than 150mPa·s. The slurries in the two tanks A and B are respectively metered by diaphragm metering pumps to 350ml, and mixed uniformly with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com