Mold special for direct-pressing forming of bathroom ceramic blank

A ceramic billet and mold technology, which is applied in the field of forming molds for sanitary ceramic billets, can solve problems such as difficult demoulding, damage, and lack of water absorption and air permeability, and achieve high strength, high strength, good water absorption and air permeability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

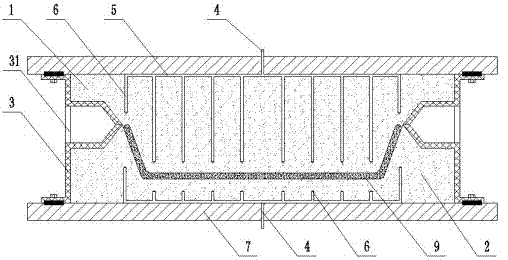

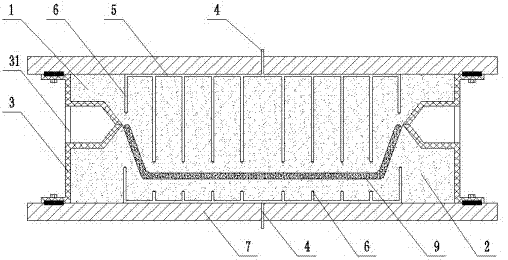

[0016] Such as figure 1 As shown, the present invention provides a special mold for direct pressure molding of sanitary ceramic blanks, including a male mold 1 and a female mold 2 that cooperate with each other. The male mold 1 and the female mold 2 are composed of water-absorbing and breathable K-type gypsum. 1 and the side wall of the female mold 2 are provided with two upper and lower steel mold sets 3 that constrain their deformation, and the two steel mold sets 3 are concave inward at their joints to the edge of the cavity formed by the male mold 1 and the female mold 2, And the vertical side walls of the two steel mold sets 3 are provided with a support block 31, and the upper and lower walls of the male mold 1 and the female mold 2 are connected to the mold steel seat 7 of the hydraulic equipment through the gasket, so when the mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com