Non-standard mold for hot runner of outdoor measuring cup

A hot runner and measuring cup technology, which is applied to the field of non-standard molds for outdoor measuring cup hot runners, can solve the problems of demoulding of cylindrical deep-walled plastic parts, molding failure of plastic parts, and production waste, saving materials, reducing mold height, reducing The effect of manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

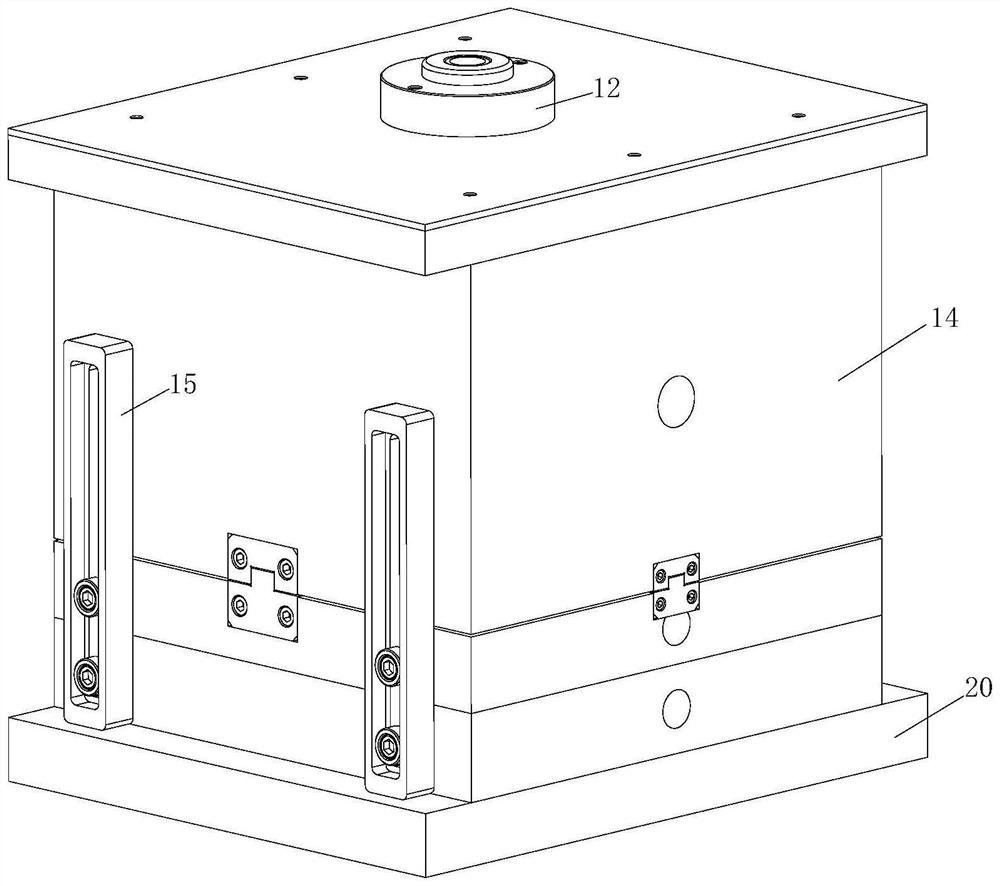

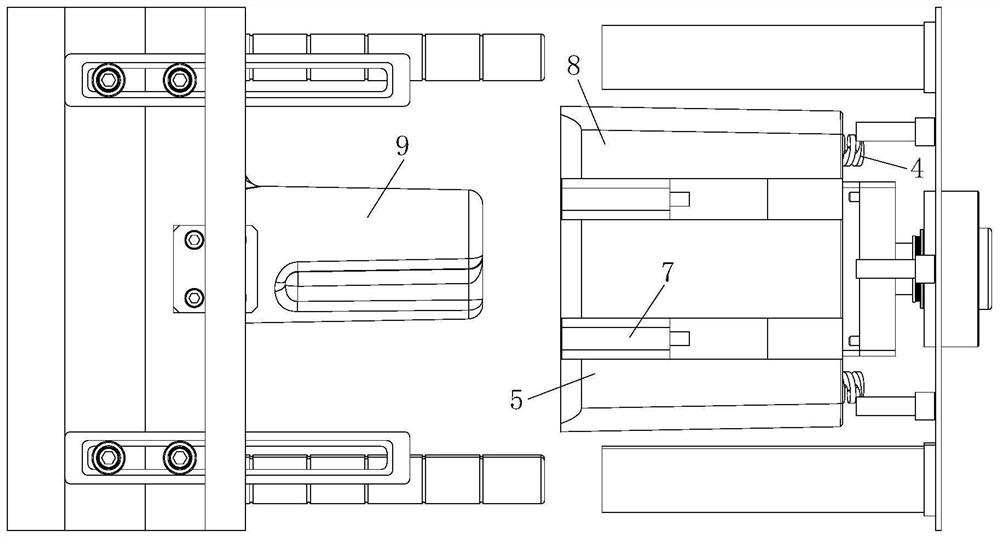

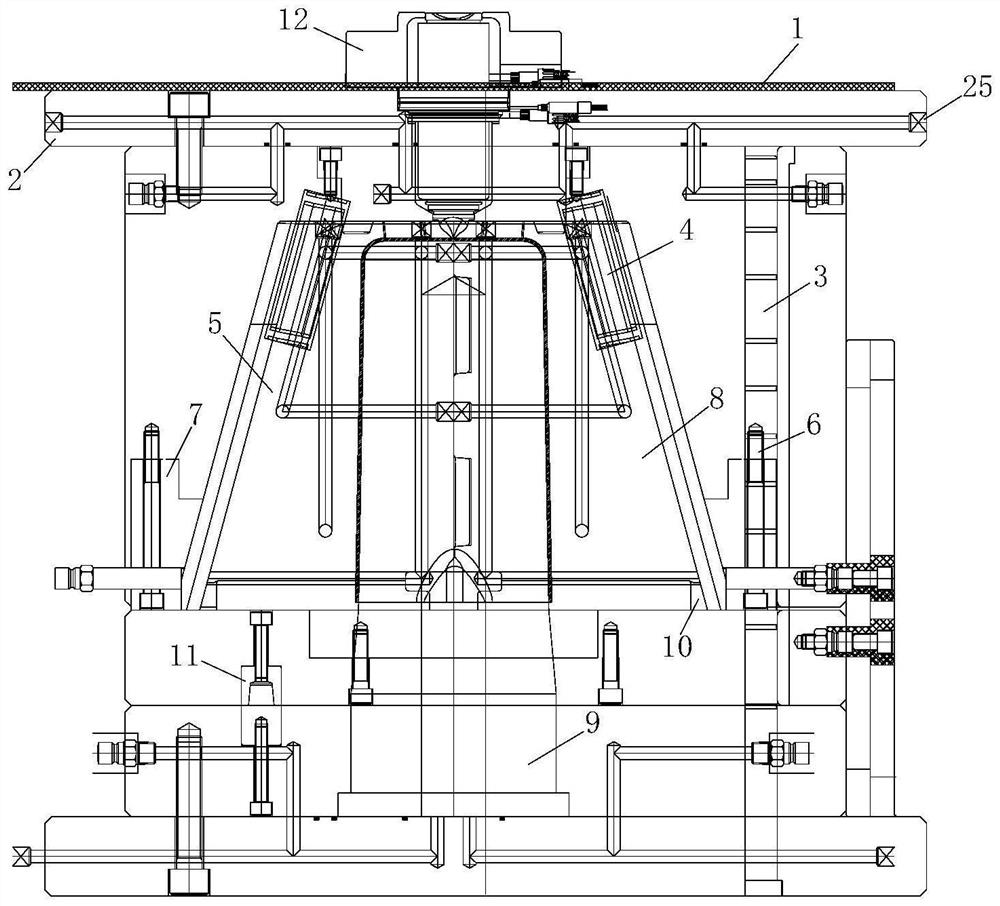

[0029] Such as Figure 1 to Figure 4As shown, the outdoor measuring cup hot runner non-standard mold described in the embodiment of the present invention includes a fixed mold seat plate 2, and a hot nozzle collar 12 is fixed on the top of the fixed mold seat plate 2, and the inner part of the hot nozzle collar 12 runs through A hot runner nozzle 23 is connected, the bottom end of the hot runner nozzle 23 is connected with a partition 13, the bottom end of the partition 13 is fixed with a cup bottom outer wall insert 22, and a fixed template 14 is fixed outside the partition 13, The bottom end of the fixed template 14 is slidably connected with a movable mold push plate 18, and the bottom end of the movable mold push plate 18 is slidably connected with a movable template 19, and the side of the movable template 19 close to the movable mold push plate 18 is fixed with an inner wall type The core insert 9, the inner wall core insert 9 is connected through the movable mold push p...

Embodiment 2

[0039] Such as Figure 7 As shown in Comparative Example 1, another embodiment of the present invention is: a heat transfer cavity 26 is opened inside the inner wall core insert 9, and a pressure plug 27 is slidably connected to the inside of the heat transfer cavity 26, An extrusion spring 28 is fixed inside the pressurization plug 27, and a sliding plate 29 is fixed on both sides of the extrusion spring 28, and the sliding plate 29 is slidably connected with the pressurization plug 27, and the bottom end of the pressurization plug 27 is A connecting rod 30 is fixed, the bottom end of the connecting rod 30 is fixed with a terminal 31, both sides of the terminal 31 are fixed with a judgment contact 32, and both sides of the judgment contact 32 are provided with a circuit contact 33, The side of the circuit contact 33 away from the judgment contact 32 is fixed with a return spring 34, and the return spring 34 is fixedly connected with the inner wall core insert 9; when working,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com